.

A Word From GPLN: Issue 75 / May-June 2020

Pre-existing troubles in freight forwarding due to the impact of Covid-19 have intensified, according to Transport Intelligence (TI) latest research which reveals that the global freight forwarding market could contract by 7.5% in 2020 as a result of the crisis, projecting a second consecutive year of negative growth. The analysis of the impact of COVID-19 indicates an extremely challenging year ahead for forwarders which was already struggling from the US-China trade war, falling production in key markets, and a wider economic slowdown. The new research shows that, in a best-case scenario, the impact of COVID-19 will drain 2.0% from global market value but this is also depending on the easing of social and economic restrictions in the second half of the year. If the public health crisis endures and the lockdown measures seen across much of the world so far in 2020 remain, the fall in market value will be much steeper. Under such circumstances a worst-case scenario would impact regional and country markets hard, especially the US market which is projected to contract by 10.8%. However, there are reasons for hope with signs that Asian markets are emerging from the crisis and an increasing momentum in Europe behind an easing of restrictions, at least in certain sectors of the economy.

As announced earlier, we have postponed our AGM in Casablanca from this year to May 15-17 in 2021 at the Parkhotel in Bremen/Germany, just ahead of Breakbulk Europe (May 18-20, 2021), so that our delegates can combine next year both events in the same city. All relevant details are published on our dedicated AGM page of our website. This is obviously subject that the world is back to normal by then.

Breakbulk Europe has been also rescheduled and will now take place from September 29 to October 1, 2020. GPLN will exhibit with a spacious stand in the main Hall 5 of Messe Bremen. So far following GPLN members will join our stand: Agence Maritime Mohab/Tunesia, Brelog/Germany, Falcon International/Canada and Unishipping International/Bulgaria. Right on the day Breakbulk Bremen starts in the evening, on September 29, we are organizing again our renowned Heavy Lift Maritime and Transport Seminar at the Parkhotel which is located within walking distance to the exhibition center. This technical course is also open for non GPLN members and offers a great opportunity to learn more about Heavy Lift Shipping and expand technical abilities and knowledge for project cargo business. More details are available on our website. Both our participation at the Breakbulk Expo and our Seminar are obviously subject that we’re back to normal conditions allowing us to travel and participate safely.

Depending on the development of the Covid-19 situation in USA we might also exhibit at Breakbulk Americas in Houston which was postponed from end of September to November 3-5, 2020, but we will not participate this year in Breakbulk Asia in Shanghai which was rescheduled from March to August 2020.

Stay safe and healthy!

Your GPLN Team

| New GPLN Members / March – April 2020 | ||

| Armenia | Yerevan | Greenroad Armenia LLC |

| Bolivia | La Paz | Greenroad Bolivia SRL |

| China | Shanghai | Shanghai Greenroad International Logistics Co., Ltd. |

| Ethiopia | Addis Ababa | Greenroad Ethiopia Logistics PLC |

| India | Mumbai | Epitome Logistics LLP |

| Senegal | Dakar | Greenroad Shipping & Logistics SARL |

BATI GROUP handles flat-rack project

GPLN member BATI’s project team recently handled flat-racks from Turkey to Oman. The flat-racks were loaded in Istanbul and delivered to the port of Ambarli outside Istanbul, where they were covered by a tarpaulin. The cargo was afterwards shipped from Ambarli port to Duqm port in central-eastern Oman. In another flat rack movement from Turkey to Oman, BATI shipped 8 flat racks from Izmir to Duqm. The cargo had different sizes and was lashed to flat racks, each of them weighing around 12 tons. BATI’s project team successfully coordinated and executed this task from home where all employees are presently socially isolated.

BATI GROUP ships boiler

GPLN member BATI would like to proudly announce the latest project executed by them. A 52 tons boiler was transported together with its accessories from Gunzenhausen (Bavaria) to Hamburg with a lowbed trailer. The boiler who had a dimension of (L) 9m x (W) 3m, was shrink-wrapped and delivered to the port where all items were loaded on to a breakbulk vessel from Hamburg to its destination in Tianjin, China. The total cargo volume was 250 CMB and was successfully handled by BATI GROUP.

FOX Brasil coordinates various logistics moves

GPLN member FOX Brasil Project Logistics has recently shipped a backpressure turbine, measuring 6.10 meters long, 4.2 meters wide and 3.2 meters high, along with its accessories from Brazil to North America. What makes this project special is that the customer has a sustainable business model to produce paper without cutting down trees, co-generate green energy with the steam turbine shipped, and recycle water from the industrial processes. To produce a single ton of paper, 250 cubic meters of water is needed. Through investments in new technologies like this backpressure turbine equipment, the recycling of the very same 250 cubic meters of water, can reach a 92 percent level of recycling. FOX Brasil’s project team intensively worked on the complete planning and execution for the road transportation, from the shipper up to the port of loading. Main challenge was to manage the logistics restrictions during the COVID-19 peak that included: Deadline to get the road permits / Restrictions for out-of-gauge cargo and adverse weather conditions / Finding a suitable vessel to assure the safety of the cargo / Under deck shipment guaranteed /Shortest transit time to avoid delay on project kick at job site. The team met all of the safety requirements on the road and at the port, making a safe move not only to its clients, but also for FOX Brasil’s partners and team.

FOX Brasil handled also successfully the logistics of 4 x out of gage components, composing a boiler, destinated to a biomass power plant at Brazil’s country side. Description: 1 Convection tube (Lx W x H in meters) 12,550 x 4,38 x 3,40 / 1 Hearth 10,700 x 3,85 x 4,20 / 1 Economizer 10,880 x 3,85 x 2,65 / 1 Combustion Chamber 11,450 x 3,75 x 3,75. FOX Brasil’s team has managed the logistics from the sea freight, receiving under hook on delivery 1000km inside the country at job site. A route survey was performed previously for the whole project management. Occupational Safety and Health rules were specially taken into account, due to the high risk for contamination during the Covid-19 outbreak in Brazil.

BATI handles shipments to overseas detinations

GPLN member BATI Group of shipping companies has been active during the Co-Vid19 days acting as the Agent of Messrs Rolldock in Turkey. MV Rolldock Sky has transported Stators and accessories to Gulluk, Turkey from Europe during the pandemic where BATI have performed as the port agent at Gulluk and organized port clearance together with unloading operation. Although it was quite a challenge to work with the new Co-Vid19 regulations in force, BATI has successfully arranged clearance up on arrival to get the berth. Vessels’ operation took slightly more than 24 hours (in and out) to unload about 1125 cbm cargo with no night shift. It was a spotless operation for all parties.

BATI Group has also successfully completed yet another flat rack shipment while taking all necessary hygiene precautions with regards to the Covid-19 pandemic. The company recently shipped three 40-foot and 20-foot flat racks with a total weight of 50 tons from Turkey to Australia. The goods were picked up by the shipper and transported to BATI Group’s warehouse to be disinfected by its team. Following the disinfection process, the goods were shrink wrapped and covered with a tarpaulin, ready for shipment.

Furthermore the latest project executed by BATI was a 52 tons Boiler which was shipped out of Gunzenhausen to Hamburg with a lowbed trailer together with its accessories. The boiler, 9-meter-long and 3 meters wide, was shrink wrapped and delivered to the port. All pieces were loaded on a breakbulk vessel from Hamburg, Germany to its destination in Tianjin, China. The total volume of 250 cbm has been successfully handled by BATI Group.

Another heavy load performed by BATI Group, was to Australia. BATI performed to engage a Main Frame Raptor and Bowl to the vessel which included pre carriage, warehousing, fumigation, shrink wrapping, lashing and all other necessary services. The heaviest part of the cargo on skids with 50 tons required special lashing with steel ropes and cables during pre-carriage and was finally placed to the container vessel as Break Bulk after fumigation at Mersin warehouse which took about a week. Thanks to all parties concerned to make it happen successfully.

The BATI Group Boat Transportation team has finally successfully delivered another beautiful boat to Bodrum where green meets turquoise. This is a great boat if you are looking forward to entertain 12 guests while having an open cockpit. The boat can reach 40 knots. These features are great to cruise around Bodrum. We have transported the boat to Bodrum, Turkey from Begunje, Slovenia. The boat was 11 meters long and 3,6 meters high. Once again, we were happy to add another boat to our portfolio while leaving a big smile on our customers and yacht owners face.

SARR completes various transportations

SARR Freights, a member of the Global Project Logistics Network (GPLN) in India, has recently successfully executed a complex Multimodal Transportation project from Mangalore to the Kalpeni Islands, Lakshadweep, India. The shipment comprised of a 100-Ton capacity Lattice Boom Hydraulic Crawler Crane and a 30-ton Tyre Mounted Mobile Crane. SARR undertook the turnkey project which included road transportation, stevedoring, port handling and towing operation from Mangalore Port to Kalpeni islands with a barge/tug combination. To compete the project, additional services such as constructing a Jetty due to poor infrastructure, dismantling of the cranes, insurance, port documentation and acquisitions of approvals were required. The project was completed despite the additional obstacles due to the nationwide lockdown. In addition to its international undertakings, SARR has extensive prior experience in coastal movement in India. Aside for opening a new route from Vizag to Northeast India route through Bangladesh a few years ago, SARR has completed many challenging turnkey projects involving multimodal freight forwarding and freight management services for the Indian govt. in Andaman Islands. SARR continues to undertake challenging projects and pioneering solutions for various government entities and multinational ventures.

SARR Freights completed also a turnkey project transporting heavy cargo via road in North India. The cargo comprised of a LP Turbine Rotor, weighing 90 MTS, (Dims: 8.8m x 4.65m x 4.16m) & HP Turbine Module, weighing 95 MT (Dims: 6m x 3.2m x 3.7m), among other heavy cargo. The haulage was from Anpara (Uttar Pradesh) & Haridwar (Uttrakhand) and included disassembling cargo, loading, transportation and unloading at the final destination. SARR completed the project within a week, deploying the relevant equipment and labour, covering ~1,000 km distance.

Furthermore, SARR Freights has completed its latest shipment of Railway Coaches (60-70 MT each) & Locomotives (130 MT each), amidst the nationwide lockdown, for their client in Jammu & Kashmir. After completing transportation of 24 railway coaches & locomotives last year, this shipment was part of another 20 coach & locomotive movement undertaken by SARR Freights. The shipment consisted of Railway Coaches, each having a dimension of 22.3m x 3.34m x 4.05m and weighing 60-70 MT. The Scope of Work included providing cranes, other handling equipment, and labour required for dismantling and loading the cargo onto the trailers, under supervision of the client’s engineers. SARR was also responsible for the entire transportation at unloading at destination. The haulage was from Udhampur (J&K) to Srinagar (J&K), covering a distance of approximately 400 kms and made challenging with the hilly terrain and political uncertainty in the region. After 3 decades of experience in this area, the SARR team has developed extensive expertise and a deep understanding of local infrastructure, terrain & local politics. The unprecedented nationwide lockdown and extreme political volatility of the region, however, produced additional challenges for the movement.

The project was executed seamlessly within weeks, overcoming many typical and atypical obstacles. SARR worked with local authorities & government for the necessary permissions. The 5 meters height cargo was maneuvered through challenging road conditions, culverts, political instability and adverse weather conditions such as heavy snowfall and landslides. The route consisted of passing through the Chenani-Nashri and Jawahar tunnels, and required additional security for the safety of the cargo. The SARR team was able to capitalize on its experience and successfully execute the of the ongoing project.

Global Shipping Services moves Phoenix Art Project back to China

The Phoenix was in display in many museums and churches around the U.S. After 2 months of storage, the artist decided to move them back to China and we arranged the transport from New Jersey, USA to Tianjin, China. The job consisted of 13 flat-bed pickups and storing for 2 months. We had to do some work with the metal pallets to make pieces fit better on the Open Tops, including taking specific bolted pieces off pallets to fit into High Cube containers to reduce the cost. The final number of containers was 1 x 40’HC, 2 x 40’OT, 6 x 40’HC FR.

About the artist: Drawing inspiration from the contemporary realities of his fast-changing country, Chinese artist Xu Bing spent two years creating his newest work, Phoenix. The installation features two monumental birds fabricated entirely from materials harvested from construction sites in urban China, including demolition debris, steel beams, tools, and remnants of the daily lives of migrant laborers.

GPLN member Global Shipping Services handled also an import shipment of a heat exchanger from Angola. The cargo measured 525 x 132 x 132 inches with a total weight of 115,741 lbs. / 52,500 kgs. The unit arrived to be refurbished and will be re-exported to Angola after the work is completed.

Brelog moves Agriculture and Farming Equipment to China

Besides containerized services for ‘high and heavy’ shipments the team of GPLN member Brelog from Germany always considers RoRo (roll on – roll off) as a service option. For our customs we manage the most efficient transport from whole Europe to the port and link it with the best seafreight option. We recenlty moved a sugar beet harvester for a Chinese customer and used RoRo as the most efficient option. Dimensions of 15,20 x 3,00 x 4,00 m and up to 32 tons of weight are part of our daily portfolio. We arranged the transport of the sugar beet harvester from Austria to Hamburg and managed the seafreight by RoRo. Containerized services for ‘high and heavy’ shipments are a key element of Brelog’s forwarding solutions. Especially the handling of flat rack containers is a daily work of our team. We also moved a corn harvester for a Chinese customer from Germany to China and use a 40′ flat rack container as the most efficient option. The dimension was 8,20 x 3,05 x 3,88 m and 16,5 tons of weight. Dismantling, packaging, documentation and transport – one stop shopping at ist best. We also moved grassbaler for a Fareast customer from Europe to China and used RoRo as the most efficient option. The dimensions was 9,60 x 3,05 x 3,60 m and up to 145 tons of weight per vehicle. High, heavy, oversized, projects – this area is one of the focus areas of Brelog. Whenever your cargo is exceeding standard dimensions or is even part of a project we and our specialists take over. In this case our shipment (n autoclave) had a size of 415 x 415 x 392 cm and a weight of over 17 tons. We arranged packing, pre-carriage (including road permit and escort vehicle), customs handling, shipping and on-carriage. Our team also arranged the lifting by shore crane and synchronized the entire door-to-door process. We are taking good care – also in this case and made sure that project shipments of all sizes reach their destination in best conditions and in time.

Punto System handles time critical shipment to Greece

GPLN member Punto System recently handled a time critical shipment of one case of 793 kg containing spare parts urgently needed for a broken gas piping site in eastern Greece. Reacting to a really short notice under Covid-19 lock-down emergency, Punto System designed a tailor-made solution for this critical case integrating freighter liner service to a European hub and full charter flight up to the country of the final destination. The cargo was collected on a Thursday evening in Houston and boarded as priority cargo onto Cargolux freighter to Luxembourg taking off during the night. At the same time a full charter AN22 aircraft was booked and positioned on the parking lot at Luxembourg, waiting to receive the incoming freight coming from United States. The Cargolux freighter landed on Friday evening and transshipment operations were performed under priority.

The ramp airport staff transferred and boarded the cargo onto our charter aircraft during Friday night, allowing a sharp on time departure to Athens on Saturday morning. The charter aircraft landed at this destination towards noon on time for the import clearance and same day express delivery to the destination site by a dedicated truck.

RoRo is the clear choice for Rail Cargo

There are roughly 619 passenger rail projects including mass transit, light rail, heavy rail and high-speed infrastructure in the world, and these numbers are only likely to increase given the rising population and urbanization. Rail manufacturers look for transport and logistics carriers that offer the best solutions for their rail products from multiple origins going to multiple international destinations. One may ask what mode of ocean transport is the best for shipping rail cargo. Let me outline the three top advantages of using RoRo (Roll-On Roll Off) vessels.

Reliability: Rail projects are commonly planned years in advance, with railcars produced in one or more origins and then transported internationally to meet a project deadline. Timing is therefore critical when delivering rail cars, so having a liner service that offers frequent sailings and fixed schedules gives the customer the chance to plan ahead; consequently, reducing both risk and overall costs.

Safety: Loading breakbulk cargoes such as rail products on RoRo vessels is quite different in that there is no high lifting involved. The railcars are lashed and secured on roll trailers equipped with integrated rails, and are simply rolled on board the appropriate deck. For railcars transported on truck-trailers, our specially designed Höegh bridge allows the direct transfer of railcars from the truck-trailer, to the roll trailer. This makes the operation safer and more efficient than other modes of transportation as it ensures safe handling regardless of weather conditions and avoids possible damage often caused by lifting heavy commodities. The safety continues during ocean transport, when stowing the cargo underdeck in ventilated cargo holds. Protected from elements such as seawater and humidity the valuable commodities are kept safe, clean and dry until they reach the port of destination. This means that customers do not need to pack the cargo, making it a more affordable option than other transport methods.

EGL (Kadmar Group) successfully completes the latest order

On 28th May 2020, GPLN member Egyptian Global Logistics (EGL), and a subsidiary of KADMAR GROUP completed transportation of two heavy lift vessels. The site was located about 900 km from the port (our engineers suggested using the longest road to avoid old bridges on the costal road and to save time for civil work as the client insisted on the delivery of vessels before the 28th May) It was a quite challenging operation scheme that was performed and completed, despite the difficult conditions.

Receiving the cargo at the container terminal that unloaded the cargo with terminal gantry cranes. Current circumstances: COVID-19. Mandatory daily curfew: from 17:00 till 06:00. (Transportations were effected during El-Fitr feast). Vessel dimensions: 9.6 m x 5.5 m x 5.4 m. Weight: 117 tons/each. Thanks to EGL Project Team for cooperation. EGL continues to impress the market with the well-trained staff along with the latest fleet equipment and technology in Egypt. EGL achieved this success through careful planning without sacrificing safety aspect in order to meet clients demand.

Polaris Projects handle cargoes during Covid-19 pandemic period

GPLN member Polaris Shipping Agencies LLC (United Arab Emirates) project team were working full time even during the pandemic period to keep customer satisfaction at the highest levels with our professional services. We have arranged several jobs as listed below.

They recently completed shipment of 1 x Unit M701F Rotor for Turkey which is part of total shipment of around 6 x Rotors to several destinations. Due to the time sensitive nature of the shipment and our close relation with CMA CGM we were able to secure space on one of their regular container vessels with fixed sailing dates to meet with deadline for arrival at Turkey. The rotor was promptly received by our partners on arrival at Port Iskenderun on nominated heavy duty axles and further delivered by road safely to the final destination.

Polaris were also awarded door to door movement of 8 packages of burner boom board side with booms ex UAE to Bahrain which had a shipping dimension of 28.50 x 2.30 x 2.85 m (L x W x H) and weighing around 18 MT. Due to unavailability of regular break bulk liner vessel in this sector and since shipment had to be executed in different lots the available option of part charter was working out expensive for the customer.

However, Polaris project team negotiated and managed to have a contract signed with one of the RORO Carriers with their confirmation to position 72’ long Mafi’s according to clients required schedule and Polaris project in house team who arranged the origin operations including securing of cargo on to Mafi’s at the time of RORO vessel in port.

Finally, the shipment was completed on schedule to the satisfaction of all parties concerned. Furthermore, Polaris Projects successfully handled also a time sensitive project shipment of Rail Wagons and Motor Car with cranes ex Saudi Arabia to Italy in coordination with GPLN partner Gruber Logistics from Italy. Polaris project team was responsible for inward movement of above shipment into Saudi Arabia in 2018.

Since our team was fully updated on the import documentations and procedures it helped our partner to handle the re-export process smoothly, even though there was a curfew imposed due to the Covid-19 Pandemic and all government offices were working with reduced staff, including Saudi Arabian customs and traffic authorities. Due to the sensitive nature of the shipment and to be transported under clients strict quality guidance, Polaris ensured that the required pre-shipment meeting was arranged with all concerned sub-vendors for them to be aware on the procedures that had to be followed during the transport and to avoid any incidents during the handling.

Polaris scope included the coordination with shippers, sub-vendors for correct documentations, route survey and road adjustments with completion of all HSE requirements, completion of customs formalities, police permissions etc. considering the curfew hours, pick up on special axles and stuffing, securing on flat racks and smooth ocean freight arrangements.

Shodesh Shipping handles biggest shipment in Bangladesh

GPLN member Shodesh Shipping has recently completed another charter vessel named M/V Happy Dragon for an important project. When you handle cargo of the biggest project of your country and if the shipment is the biggest of that project then you are feeling that you should be more confident and prouder to be an identity of a company like Shodesh.

This shipment is the biggest so far for the Rooppur Nuclear Power Plant Project and even bigger than in the past and we were therefore very proud to be the exclusive agent in Bangladesh for handling this mega project. We have used total 2 barges to move the cargo by river and 221 trucks/trailers to transport the cargo by road from Mongla port to Rooppur NPP project site. At the project site we have used 1 x 300 tons Crawler Crane, 1 x 250 tons Crawler Crane, 2 X 300 tons Grove Cranes and 1 x 50 tons Mobile Crane for unloading the cargo. We have just shared a part of cargos out of multiple hundred cargos. Facts and figures: POL: St. Petersburg, Russia / POD: Mongla, Bangladesh / Commodity: Nuclear Power Plant equipment / Packages: 734 packages including HL, OD and general cargo / total weight: 2007106 kg / total volume of cargo: 6024.27 CBM

Protranser International Logistics’ moves

From the beginning of March to April in 2020, during COVID-19 period, GPLN member PROTRANSER’s team kept working on a dismantling and packing project for precision instruments which needed to be returned to Japan for maintenance from Chengdu, Sichuan province, Southwestern part of China, 2000 km away from Shanghai. Their team handled also 1*20’GP container import to Hong Kong, China by air. They were in charge of import customs clearance for the container in Shenzhen and delivery by truck to the jobsite in Guangdong province. Cargo description: Fuel assembly deformation measuring equipment. Furthermore, they delivered 300 tons of tomato paste to Japan from Xinyang province, northwest China via Tianjin. The distance was over 3000 kilometers from Xinjiang to Tianjin. Protranser handed also 12 pieces of autoclaves from Shanghai to India for a client and the service included picking up cargo from the factory and port service. Cargo description: Autoclave: 1,68*2,6*2,8 m, 23tons*12.

Furthermore, their team chartered recently a roro vessel for their client to transport more than 60 different kinds of vehicles, over 6,000 CBM, from Shanghai to Massawa, Eritrea. This shipment was consisting of livestock carriers, buses and spare parts. Finally, PROTRANSER’s team was executing the transportation of millions of face masks to Europe for protection against COVID-19 by full charter plane, contributing to the global anti-epidemic (COVID-19 was characterized as a pandemic by WHO on March11, 2020). All masks were delivered by another 3 planes in April, besides the first one in March 2020.

Some safety tips. Please remember W-U-H-A-N:

W – wash hands carefully and often

U – use mask properly

H – have temperature checked regularly

A – avoid large crowds

N – never touch your face with unclean hands

Way of handling Breakbulk cargo by EUKOR advances over time

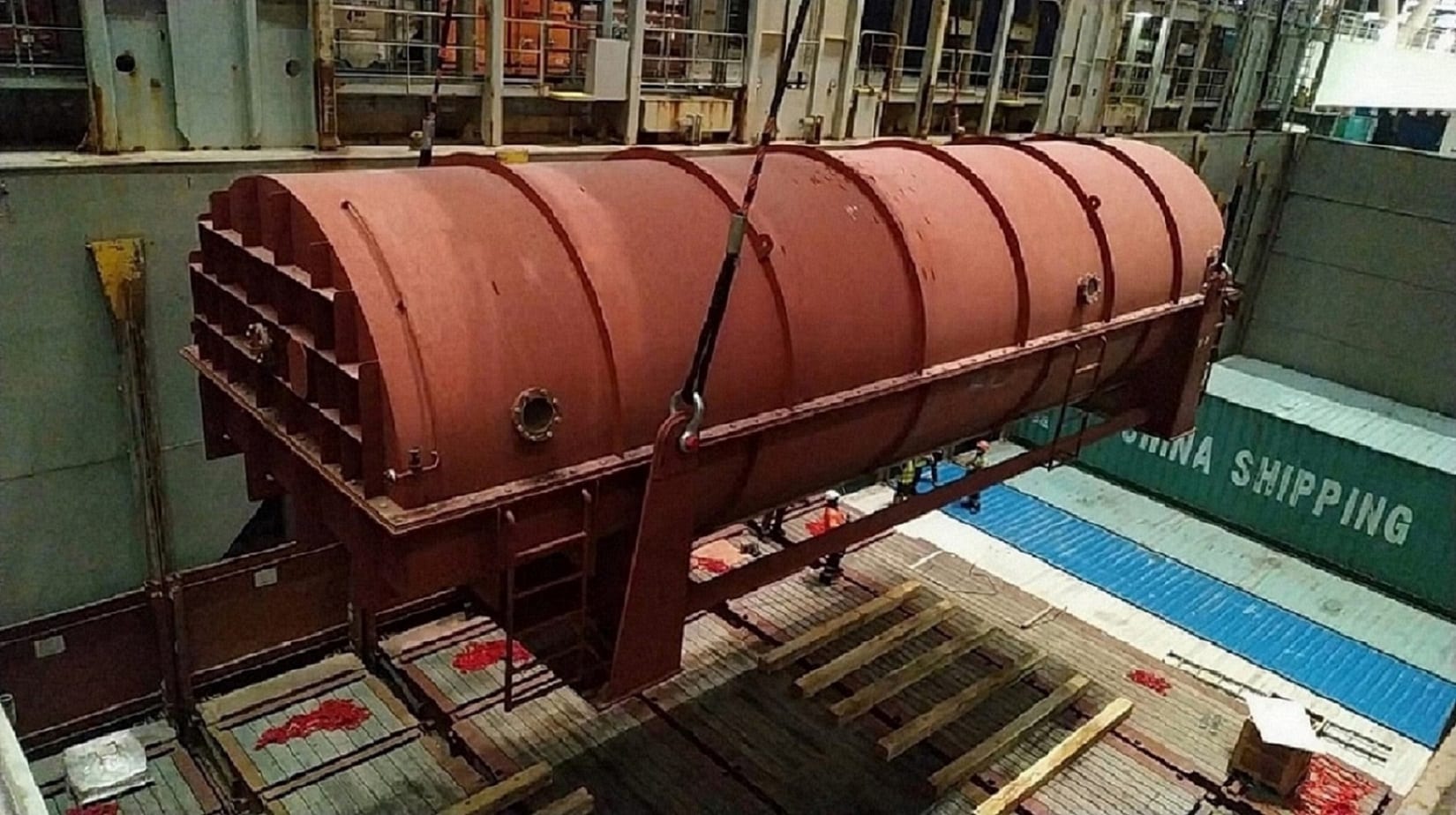

Usually when the dimensions of a cargo exceed the ramp width of a vessel, it is inevitable to think that the carrier would turn down the request saying “We are extremely sorry but we cannot help you with your cargo because of its size.” But guess what? That’s not how we approach our breakbulk cargo customers. We try to find the best possible way to handle various type of non-self-propelled cargo from aviation to boats, construction equipment, power generation equipment and railcar and many more. Especially, with the knowledge of ports worldwide and know-hows, our strong team of experts provide safe and smart solutions. Here’s a noteworthy case of EUKOR handling breakbulk cargo – a cargo wider than q-ramp – in a very brilliant way. A few weeks ago, relatively big static cargo without wheels arrived at the port of Bremerhaven, Germany. Those cargoes were two big size so-called ‘under hull frames’ bound for a shipyard in Singapore for the construction of a drilling rig. In the first place, simply by looking at the specifications of cargo, measuring 8.4 meters long and 7.2 meters wide, it seemed like the cargo could not fit in to the ramp of our vessel ‘Morning Crown’ as width of the cargo was wider than the ramp of the vessel. “We received the inquiry for shipment of this cargo from a project forwarder whom we have known for many years. Due to the dimensions of this cargo which exceeded the ramp width of the vessels in position, we needed to find a solution for loading this cargo. We collaborated closely with customer from preparation to execution. And after a few times of pre-testing with experts at EUKOR, ‘Eureka!’ there came a perfect solution from Cargo Superintendent Specialist Mr. Frederic Verhofstede and his team,” recalled Mr. Per Moe, a customer service agent and sales agent for EUKOR in Sweden. Per also added that “This shows the flexibility of our RORO solutions and our team looks forward to more oversized cargo inquiries in the future.” Two 40ft roll-trailers, most commonly used cargo handling equipment that can cater cargo up to 12 meters long and 2.5 meters wide, were used to load this cargo as it could not roll on and off the vessel on its own.

If the cargoes were to be handled in the traditional way, we might have transferred cargo from trailer to the handling equipment at the port yard. But it had to be treated differently this time. We placed an empty 40ft roll-trailer at the entrance of ramp, and then transferred the cargo from trailer by lifting the cargo utilizing a mobile crane at the port. Simply put, we stuffed the cargo onto the handling equipment on the ramp not at port yard. The Cargo Superintendent Specialist Mr. Frederic Verhofstede added that “The most noteworthy yet difficult part for loading this cargo at Bremerhaven was that the width of the cargo was slightly wider than the q-ramp. Our team put our heads together and tried to think outside of the box to come up with best solution for this project. Our handling methods focused on minimizing number of switches while loading and discharging process, significantly reducing the risk of damage. We are proud that our way of handling breakbulk cargo advances over time.”

ALPHA Projects & Logistics handles transport of project material

Despite a challenging Corona period and a forced lockdown for many suppliers in Italy, GPLN member ALPHA Projects & Logistics from Genoa/Italy performed a successful transport of project materials from Milano, Italy to Rostov-on-Don, Russia. The shipment consisted of up to units’ weight of 58000 kg and dimensions of 15,82 x 4,95 x 2,95 m (L x W x H). The Italian supplier managed to obtain special approval to load this urgent cargo at their premises. Despite unexpected bridge closure due to construction/reinforcement work and other extended roadworks that made the previous route impossible, we managed to obtain necessary permits for a “last minute” route change and the units were transported safely by special trucks from vendors premises to Porto Maghera without any significant delay. At Porto Maghera the units were then successfully loaded, without trouble and shipped on a charter vessel to Rostov-on-Don. Where there is a will there is a way!

ALPHA Projects & Logistics from Netherlands performed recently also a project shipment of steel pipes from Constanta, Romania to Balikpapan, Indonesia.

Cargo spec: 1.594.186 kg steel pipes. Due to tight delivery schedule and safety reason the pipes were loaded into 65×40′ DC and shipped by FCL vessel from Constanta to Balikpapan, Indonesia.

Despite a challenging Corona period and a forced lockdown for many suppliers in Italy, ALPHA Projects & Logistics GENOA performed a successful transport of project materials from Milano, Italy to Rostov-on-Don, Russia.

Shipment: up to units weight of 58000 kg and dimensions 1582x495x295cm LWH

The Italian supplier managed to obtain special approval to load this urgent cargo at their premises.

Despite unexpected bridge closure due to construction/reinforcement work and other extended roadworks that made the previous route impossible, we managed to obtain necessary permits for a “last minute” route change and the units were transported safely by special trucks from vendors premises to Porto Maghera without any significant delay.

At Porto Maghera the units were then successfully loaded, without trouble and shipped on charter vessel to Rostov-on-Don.

Where there is a will there is a way!

STAR Shipping delivers two heavy Gear Boxes to China

STAR Shipping Pakistan has again set a milestone in Pakistan’s logistics Industry by delivering 2 Heavy Gear Boxes from Jhimpir Wind Power Site to SAPT Karachi Port during COVID-19 lockdown situation in the mid of June, 2020. STAR Shipping was given an urgent task of lifting & shifting the aforesaid Gear Boxes, weighing 16 tons each (Dead-Weight Cargo) from Jhimpir to Karachi Port and shipping them from Karachi Port to Shanghai, China. It was an extremely hot summer weather at Jhimpir Site with humidity and dry air which made it a real difficult task for our professionally trained staff, but neither the human resource nor our equipment suffered any adversity except extreme heat. We utilized a 80 tons capacity: a certified mobile hydraulic crane for the safest lifting of Gear Boxes and 2 separate low bed carriers for the delivery of the same.

Super Cargo Transport handles cargo with cabin-load flights

GPLN member Super Cargo Transport (SCT,) a subsidiary of SCS from Vietnam has continued executing a series of air charters from Vietnam to USA. We did arrange cabin-load flights as a critical part of charter solution. This 9th charter of B777 loaded 250cbm of vital PPE products of Vietnam in the belly of aircraft & on cabin which on both passenger seats as well overhead compartment that really helped our customer to gain cost optimization. Route: Saigon-New York, USA (JFK Airport). Loaded volume: 250cbm / 50tons of PPE Products made in Vietnam.

Furthermore SCT just finished handling 2 Kalmar Super Gloria Reachstackers, 350 CBM / 110 tons from Saigon port to the job site. These were so far the biggest Reachstackers in the Asia-Pacific area. Scope of services: unloading Kalmar Super Gloria Reachstackers at Cát Lái port in Saigon, customs clearance and delivery to the job site.

CKB moves Steel Box Girders for an Elevated Toll Road Construction Project

GPLN member PT Cipta Krida Bahari (CKB Group), part of PT ABM Investama Tbk (ABM), has been awarded a project logistics service contract by the EPC (engineering, procurement and construction) company, PT Bukaka Teknik Utama Tbk (BUKK) mobilized steel box girders for the Jakarta-Cikampek II Elevated toll road construction project. This included the supply of prime movers, multi-axles, turn tables, supporting tools, lashing, wire rope, slings, chains, lightning and manpower. The total steel box girder mobilized was 422 units with the heaviest cargo being 80 tons and the longest size being 60 meters. The mobilization of the steel box girders is carried out in stages and will be completed in approximately 9 months. The mobilization of these steel box girders started from KM 9 to KM 46 which is conducted at night until morning, involving police escorts to maintain the security and safety of the project workers and traffic users. A prudent survey, operating plan analysis, routes and type of transportation were the key factor of a success delivery, which means meeting the customer’s expectation with CKB logistics’ solutions. The project was challenged by the Indonesia’s geographic and a minimum of infrastructure; thus, the company played an important role in restoring the necessary infrastructure such as strengthening local bridges so that they could be crossed by the project shipment transportation. To achieve it the operations timing precision was crucial in regards to sea transportation which was challenging due to the climate and weather changes and also local issues for the team to handle and properly manage. Nevertheless, with CKB logistics vast experience in handling this kind of projects, the cargo shipments could be successfully delivered timely and safely to the site in Jakarta.

Aero Africa appoints Jay Cameron as Director Product Development

Aero Africa, the air cargo management group, is proud to announce the appointment of James Cameron as Director Product Development, Southern Africa. South Africa born Jay Cameron comes with more than 10 years of International Experience in the Airfreight Wholesale Industry. He joins Aero Africa after spending more than 10 years with Neutral Wholesaler CFR Freight SA (Pty) Ltd. He was instrumental in assisting CFR Freight SA (Pty) Ltd Airfreight Division to become a top 10 IATA Cargo Agent working with various Freight Forwarders and Clearing Agents.

In his new position as Aero Africa’s Director Product Development, Southern Africa, Jay will be based in Johannesburg and responsible for developing the airfreight consolidation products and scheduled cargo service into the region, as well as monitoring and overseeing all shipments to and from Southern Africa. Jay has a valued image and reputation in the marketplace, both within the Freight Forwarding, Wholesale and Airline marketplace, with extensive knowledge and expertise of the industry. “We would formally like to welcome Jay to the Aero Africa team, I have had the privilege of being Jay’s client over the last few years and his service level to his clients us unbelievable. Jay, we know will fit into the Aero Africa mold as he has set the bar extremely high to continue in his journey as our Director of product development in Africa. Jay has a wealth of experience that he brings to our business and we really look forward to the opportunity of working together.” says Jade Da Costa, CCO Africa. Juergen Anwander, Germany based General Manager adds: “We as Aero Africa are proud that, despite of the difficult times we all face, an experienced and well reputed person like Jay is strengthening our management team in Southern Africa. With his experience and knowledge, he will definitely help us to move Aero Africa to the next level.”

Universal Transport master a challenge with flying colors

“Extraordinary” is day-to-day business for a heavy-duty logistics company like Universal Transport. However, modules for a huge tunnel boring machine are not on the daily program either. In June, the experts at Universal Transport were able to proof that they can get these goods to their destination smoothly like any other.

The transport started at the port of the Lower Silesian town of Malczyce in South-Western Poland. From there it was transported with a special truck to Lodz in the heart of Poland, around 260 kilometers away. The largest module transported was eight meters wide and weighed a respectable 185 tons. With a total weight of 309 tons, the truck loaded with the largest part was 36.5 meters long, 7.96 meters wide and 4.75 meters high – plus a truck to push and pull.

These impressive dimensions made transport organization and route planning a challenge. The transports were run by the Universal Transport subsidiary in Poland, which also took over the securing of the route and the vehicles were supplied by the Czech branch of the heavy-duty logistics company. Thanks to its cross-border network and expertise in the different areas of heavy load and project logistics, Universal Transport can also offer exceptional international transports successfully from a single source.