.

A Word From GPLN: Issue 73 / February 2020

The mood during the recent Breakbulk Middle East conference and exhibition and in Dubai was upbeat despite the coronavirus limiting the number of visitors attending this event which was also caused to the fact that all flights from Iran, Kuwait and Bahrain were cancelled on short notice. The region’s project logistics market is dynamic and diverse and there are plenty of opportunities emerging from the renewable energy and construction sectors, besides the traditional oil and gas projects in the Gulf Cooperation Council (GCC) states. A new gas discovery in the UAE, estimated to be holding about 80 tn cu ft of gas, is shaping up to be one of the world’s biggest gas finds since the Galkynysh field in Turkmenistan in 2005. The discovery in Jebel Ali, operated by Abu Dhabi National Oil Company (ADNOC), could have far-reaching ramifications for the country, but while the initial find has generated excitement in the market, it is too early to make assumptions about the size of the total volumes. However even one-tenth of the preliminary estimate would still be enough to enable the UAE to become energy independent by 2030. At the same time, the UAE is boosting power generation from renewable energy sources and is expected to start generating power from a nuclear reactor this year.

In the meantime, the Breakbulk Asia conference and exhibition, originally scheduled for March 18-19 in Shanghai, has been rescheduled to August 3-4, 2020, as a result of the coronavirus outbreak. However, the biggest industry related event in the world, Breakbulk Europe conference and exhibition with over 11,000 industry professionals and key decision makers is still scheduled to go ahead from May 26-28 in Bremen, Germany. At the time of writing we are also planning to conduct our AGM in Casablanca, Morocco from May 31 to June 2, 2020, just after the Breakbulk event. We are in close contact with our agents, suppliers and health authorities in Morocco to stay up to date with the latest developments as the safety and health of our attendees has first priority.

Kind regards,

Your GPLN Team

Allseas ships Airbus A320/21 Cabin Crew Trainer

The transport of a fully assembled, highly fragile Cabin Emergency Trainer unit was never going to be easy all the way from Felixstowe, UK, to the Viet Jet facility in Ho Chi Minh. But GPLN member Allseas Global Logistics from UK was more than ready to take up the challenge for our client EDM, the world’s leading supplier of training simulators to the civil aviation and defence markets. The 15,500kgs high value training unit, measuring approximately 16.36 x 4.15 x 3.02 metres, was carefully loaded ready for shipment at Felixstowe requiring multiple precision lifts for this delicate cargo. Phase one of the transportation was the shipment to port Vung Tau in Vietnam. This was followed by the second phase of the project which included the careful unloading and on-carriage to the Viet Jet facility in the city of Ho Chi Minh, assisted by our GPLN partners The Freight Co. Ltd.

The high value and delicate nature of the cargo required detailed planning for the precision load, unload and on-carriage move to its final destination. Our customs clearance planning ensured the smooth transition from ship to forward carriage, all completed within a tight deadline to avoid any port waiting charges. Customer quote: “Following the negotiation and subsequent purchase order raised for the project, EDM found the process easy and with piece of mind. EDM was kept informed at all stages of the process including photos of the loading and unloading at both ports & site. The final arrival and positioning of the goods within the new training facility in Vietnam was done in accordance to our SOW requirements and within budget. In total, a seamless and first-class achievement by Allseas Global Logistics”

New Project Cargo Director for BATI Innovative Logistics

GPLN member BATI Group appointed Mr. M. Erman Atik as the new Project Director and Head of Break Bulk & Project Cargo Forwarding for BATI Innovative Logistics, effective January 13, 2020.

Mr. Atik has over 20 years of professional experience in the fields of Container Agency, Breakbulk and Oversized Cargo Transportation and Project Management for major industrial construction projects for Oil & Gas, Offshore Projects, Windmills, Solar Tech, Power Plants, Construction, Turn Key Projects. On the past he was responsible to develop and execute projects in Turkey and the Black Sea countries including Bulgaria, Romania and Georgia under the capacity being the Deputy General Manager of an important Regional organisation and he took several global assigments in his career. His solid project management and logistics skills, as well as accumulated know-how and experience will be great assets for BATI Group of Shipping Companies for the year 2020 and onwards.BATI GROUP is very proud of his announcement as not only his high attainments and technical knowledge in the industry will open a new era in our family, his personality will also give us more strength on our top principal values of Reliability, Customer focused, Value-added and Innovation. We are very confident that Mr. Atik will deliver great value, support and innovation to you and lead us as a company into the future! Please join us in welcoming Mr. Atik to the BATI Innovative Logistics family!

BATI GROUP delivers Mastercraft and Boat to Bodrum

The boat transportation team of BATI GROUP, a GPLN member from Turkey, has successfully delivered another beautiful boat to Bodrum where green meets turquoise. This is a great boat if you are looking forward to entertain 12 guests while having an open cockpit. The boat can reach up to 40 knots and these features are great to cruise around Bodrum. We have transported the boat from Begunje in Slovenia to Bodrum in Turkey. The boat was 11 meters long and 3,6 meters high. Once again, we are happy to add another boat to our portfolio while leaving a big smile on our customer’s and yacht owner’s face. BATI GROUP also delivered a brand-new Mastercraft to Bodrum which is a gateway for nearby beach towns and resorts where people enjoy watersport activities. The boat was shipped out of Miami, USA to Izmir in Turkey and after the discharge from the vessel it was loaded on a standard trailer and delivered to Bodrum.

Excellent Shipping moves Stern Ramp

GPLN member Excellent Shipping from China recently moved a stern ramp that had a dimension of (L) 10m x (W) 7.05m x (H) 0.58m and a weight of 15, 000 kg and was loaded as one piece of steel structure/stern ramp as a break bulk cargo on a 4 x 40’ Flat Rack Container with the last tier at Bay 46 under deck at the Port of Shanghai to Vancouver.

The delivery time of this project was very tight and just ahead of our Spring Festival. But even under the influence of Corona Virus, we were able to solve all difficulties, such as limited space on the vessel, found suitable barges and loaded the cargo to a large vessel and shipped it smoothly to Vancouver. We obtained also a special transportation license and arranged a professional lashing team to support the shipper for lashing day and night at the port and finally completed the task successfully on time and to our customer’s full trust.

PNI Logistics ships heavy equipment to Australia

GPLN member PNI Logistics from UAE arranged the transportation of heavy equipment’s from client’s yard in the Hamriyah free zone, UAE to Australia for a UADRAFLOAT/ DUO FLOAT project. After the completion of the project in Australia we mobilized it back to client’s yard in UAE.

The scope of work included crane handling, customs documentation, port and other department permissions, and transportation for the out bound as well as the inbound movement. The equipment used were a 100-ton crane together with a 50-ton support crane to load the heavy packages onto transport vehicles at the time of out bound shipment from client’s yard to Hamriyah port and vice versa. In total there were 29 trips necessary comprising of regular flatbed trailers, extendable trailers (18m and 24m long) and lowbed trailers. PNI transported this heavy equipment’s from client’s yard at Hamriyah free zone for a Break bulk shipment to an Australian Port on a BBC vessel. The total volume handled was 1900 CBM with a total of 38 packages ranging from 6 tons to 25 tons in weight and measuring up to 22 metres in Length.

Star Shipping handles Pakistan Transmission Project

GPLN member Star Shipping from Pakistan has once again setup a milestone by receiving a whole break-bulk cargo shipment of 4,400 freight tons “Under Hook” at Port Qasim, Pakistan, in January, 2020.

The aforesaid shipment comprising 423 break-bulk packages was received hook-hook within 2 days without any trouble. We provided a total 30 trailers to fulfill the given task of receiving the whole shipment under-hook and shifting it from the berth area to a temporary storage area inside the premises of Port Qasim. Our good relationship with stevedores, port staff, custom clearing agent & subcontractors played a major role in a swift & safe operation. The shipment was destined for the Matiari site which was successfully delivered within a few days right after the completion of the custom clearance formalities and duty payments.

No injury to any human being or equipment occurred and our plan of zero accident prevailed successfully. Such successful achievements not only increase our morale, but also boost our good-will and trust worthiness among our clients & International market approach.

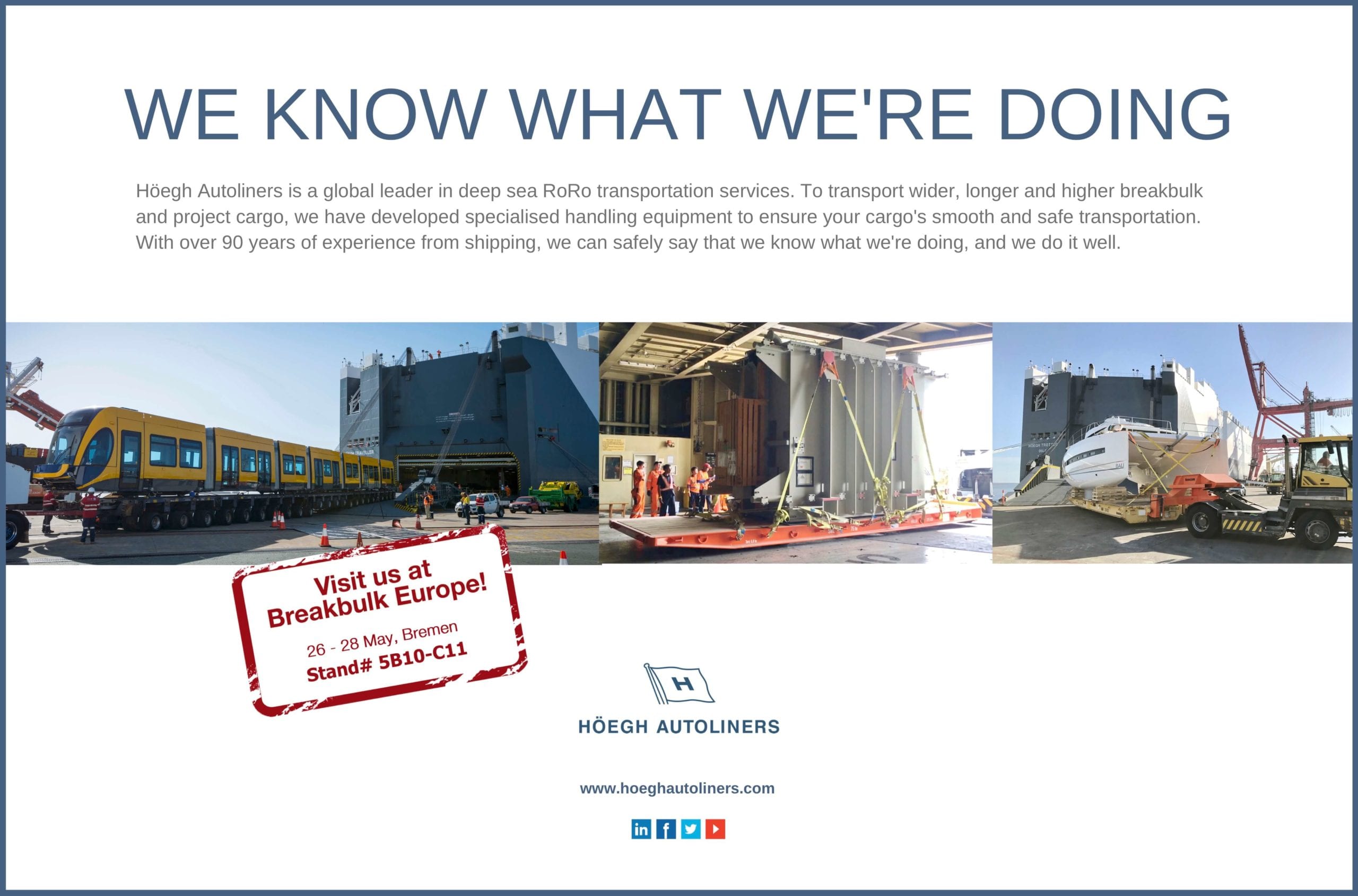

Höegh’s RoRo solution ensures safety for sensitive breakbulk shipment

Transporting sensitive cargo across the world requires careful cargo handling and meticulous planning. The stakes are even higher when transhipment is required. Recently the Breakbulk team in India was presented with the task to transport a 55 metric tonne turbine generator from Ennore to Mombasa. With Höegh’s established liner service, strategic transhipment set-up, local breakbulk competence and specialised equipment, the team devised a plan to reduce costs and risk for the sensitive shipment.

Pre-planning is crucial

Loading, stowing and discharging breakbulk cargo are delicate operations which requires meticulous planning, customised equipment and experienced cargo handling. During the pre-planning phase, the team discovered that the height of the generator would pose a challenge during the transhipment operations. With a fleet of 3300 rolltrailers to choose from, the team chose the most suitable equipment to ensure the cargo would be transported to its final destination safely and with minimal handling. Capt. Atuldutt Sharma, Breakbulk Sales Manager in India explains, “Standing at 4.3 metres alone, the height of the unit was too high for transhipment operations. Most of the vessels in the Middle East to India and Africa service have a door opening of around 5.0 metres so the solution was to use Höegh’s Superlow rolltrailer. The Superlow rolltrailer is only 0.47 metres high and is designed to load Breakbulk cargo that is 25-30 cm higher than what we were previously able to transport.”

Safety continues with transhipment

RoRo (Roll-On Roll-off) vessels are designed for cargo to be stowed and lashed safely underdeck. This is particularly important for sensitive cargo as the climate-controlled decks keep the delicate cargo safe from exposure to salt water, changing temperatures and high humidity, reducing the risk of damage during transit. During transhipment operations, the safe operations continue, as the cargo never leaves the rolltrailer it was originally transported on. The sensitive cargo is rolled directly from the vessel to transhipment terminal and onwards to the next vessel. This mode of transportation ensures minimal handling of the cargo during its entire transportation. Capt. Atuldutt continues, “The customer chose our RoRo solution as it provided the safest mode of transportation for the customers’ sensitive cargo. With the cargo safely stowed underdeck it reduced packing costs for our customer and ensures the cargo reaches its final destination in the same condition it was handed to us in.”

Time Critical Air Cargo to Angola

GPLN member Global Shipping Services’ Houston project team managed the shipment of Time Critical air cargo required in Angola for a rig down situation from IAH Houston, TX, USA to LAD Luanda in Angola. The team worked closely with air charterers, shipper and packer over a 3-week period to reduce the cargo height so we could load into 747F nose loading aircraft. After dismantling the main piece measured 42’ x 8’ x 6’11” / 23,000lbs + accessories.

Eric Drennan from the Global project team coordinated this shipment from start to completion, such as on-site meetings with the client, shipper, checked and confirmed max dimensions for the 747F option and worked with packers to build a skid strong enough but low enough to handle the cargo. Eric Drennan was also on site with the customer and attended the aircraft loading on Sunday 1st March.

Suvari Shipping makes a difference

It is easy to say there is no service available in the C.I.S and Caucasian area and leave it, unless a company like GPLN member Suvari Shipping & Trading from Turkey and Turkmenistan comes up and can offer alternatives to make a difference as a Logistics Solution Provider.

This specific project started with small toughts and was supported by maths, and when this two ingredients are coming together with experience there is one thing that can be enjoyed. We are proud of to announce that 74 peices / about 700 MT / 3600 CBM of vehicles and accessories were delivered safely from Derince Port in Turkey to Poti Sea Port at the mouth of the Rioni River in Poti, Georgia. The heaviest cargo had a weight of 30 tons and the longest measured 14 m. We would liek to take this opportunity to thank our team for the whole process in handling every step carefully and with passion.

EUKOR successfully delivers sets of windmill parts

Sets of windmill parts were delivered recently from China to South America. It was one-year-long project awarded to EUKOR, a South Korea based shipping company that specializes in port-to-port deep-sea transportation of cars, trucks, rolling equipment and breakbulk all over the world. Nowadays many countries around the globe continue to take meaningful action on renewable energy development, with an assumption that renewable energy and energy efficiency are key to sustainable growth. This is one of the reasons why more and more countries invest in building wind power generation.

EUKOR has worked effortlessly to promote that Roll-on Roll-off vessel (or RoRo) is just a perfect option for delivering crucial parts of those renewable energy plants, seeing the potential in the business. As a result, EUKOR successfully clinched an order of delivering windmill parts ex Asia to the opposite side of the world. This project has affected EUKOR breakbulk sales in many ways.

First, it was a good chance for the customer to reaffirm that EUKOR’s RoRo vessels were more than capable of delivering not only automobiles but also non self-propelled cargo. Also, this project has contributed a lot in the growth of the company’s breakbulk sales last year. “Wind turbines are known to convert wind energy to electrical energy for distribution in a more cost-effective and environmental way than other energy. We believe countries eyeing on introducing wind power as one of renewable energy sources will likely to increase in the coming years. We have already proven that we have the ability to deliver windmill parts on RoRo vessel with previous experiences of handling similar cargo to North America in the past. We will continue to focus on this renewable energy business and seek more opportunities,” said Mr. Sungwon Choi, the head of Breakbulk Sales at EUKOR. RoRo vessels don’t just carry cars but are capable of handling almost any type of breakbulk cargo, from aviation parts, and construction machinery to transformers, rail cars and windmill parts.

EUKOR’s large and modern fleet of RoRo vessels can carry single-unit weight of up to 300 tones and with door access up to 7 meters wide and 6 meters high. Transferring breakbulk cargo from its arrival trailer to a suitable roll trailer requires limited lifting only. From thereon, it’s all about moving on wheels: simple, safe and efficient.

MFC receives ETNOW Best Logistics Service Provider of the year for Project Cargo

The year 2019-2020 has been an exceptionally challenging year for MFC as it had the opportunity to execute a number of Projects from multiple locations and had to provide End to End Logistics Services. We successfully managed all the projects that were being executed simultaneously from multiple locations with varying scale highlighting the technical expertise, dominion knowledge, management capability & skill in organizing, mobilizing the manpower, equipment, vendors, and the financial resources to execute these projects in such a short time.

We would like to thank ETNOW – Business Leader of the year for this honor and recognition to award us with the Best Logistics Service Provider of the year for Project Cargo / Valuable Cargo / Heavy Lift. We as MFC would not be here today, accepting this award, without the support and blessings of our late founder Mr. Sureshchandra Agarwal. The management appreciates the effort and commitment of entire MFC Team in executing the projects, so once again a very heartful thanks to all for the continued and extended support. MFC Management

The Freight Co., Ltd. completes the transportation of 105 subway wagons

As announced last year, GPLN member The Freight Co., Ltd. from Bangkok in Thailand secured a contract to transport 105 subway wagons for the Blue Line extension from Laem Chabang Port to the subway depot in Bangkok and they are now pleased to announce that they finally completed this challenging task with the transportation of the last 3 wagons on 2nd of March 2020.

The wagons were shipped by a container vessel to Laem Chabang where The Freight Co. took care of them and moved them to the subway depot in Bangkok. The delivery period for the 105 wagons lasted around 10.5 months and virtually every weekend a lot of 3 wagons arrived at the port with the occasional lot of 6 wagons. The convoy usually left the port at 23:00 hrs. and reached the subway depot in Bangkok around 02:00 hrs. Unloading at the depot was done by the client by using hydraulic jacks. The Freight Co. had staff supervising the operation on board the vessel and on the jetty where the coaches were loaded on hydraulic trailers, as well as at the depot and provided seamless reporting to the client.

For 33 lots the transport from the port to the depot was mostly uneventful. However, for the last 2 convoys there was a construction site close to the depot. So immediate action was taken so that the last two lots could also been delivered timely.

EGL successfully completes Assuit Power Station Project

Project Introduction:

The project included one 650 MW steam thermal power plant to interconnect with the National Unified Power System (NUPS) through a 500/220 KV GIS switchyard. It is comprised of one Rankine cycle sub-critical turbine generator unit with a nominal rated capacity of 650 MW using natural gas instead of heavy fuel.

YouTube Video Link: https://www.youtube.com/watch?v=3rPVbedYyS8&feature=youtu.be

Project Execution and Completion

GPLN member Egyptian Global Logistics (EGL), subsidiary of KADMAR GROUP, completed transportation of the Assuit Power Station project. In addition, EGL (Kadmar Group) succeeded to deliver accessories and containers to the same site including the arrangement of all types of clearance formalities and getting approvals from the relevant authorities to clear containers in the port. The site is located about 850 km from the port of Dekhila on the west bank of the Nile river . It was a quite challenging operation scheme that was performed and completed, despite the difficult conditions. One of the greatest difficulties, in addition to the Project was the discharging of 4 x 228 ts Transformers and accessories. The same vessel delivered other 4 x 228 ts Transformers for another project. The port was congested, so special arrangement to berth the vessel alongside the container terminal and to secure sufficient storage space for unloading the units at the port of El Dekheila were made. Other important activities were route survey, transport study for choosing the most economical route from the port to the site including bridges study, civil work, crossing cities during the night time, moving under electric high voltage cable, removing traffic signs, removing sidewalks, removing trees all over the route, compacting the ground to bypass bridges, site preparation, soil compacting, shifting from 24 axles 2 Files configuration used during the transportation to 24 axles 2 Files. Moreover, the reinforcement of Manqabad Bridge made it incredibly hard to finish with a deadline ending after 45 days, so it took time until it was fully reinforced and ready for the heavy units. Furthermore, it was very tough to obtain authorization Yet, EGL was able to achieve success in this project through careful planning without compromising any safety aspects. For crossing the bridge, the challenge was great due to the age of the bridge and the direct crossing for a rail connection with a window of just 10 minutes between the train passing which made very difficult. Special calculations and dynamics test for the bridge reinforcement before and after crossing to make sure that the load will not harm the old bridge connecting Assuit west and east parts. With EGL to the rescue, the incredibly complicated task of building a hyper-modern power station was achieved safely. Today, the power station is helping Egyptian citizens to further grow their economy in ways that no one ever imagined.

EGL people engaged in the project

83 staff members including: engineers, technicians, administrators, safety officers, escort staff, drivers, mechanics, electricians, riggers and custom clearing staff. EGL managed to provide the whole scope of operation and avoid increasing costs of overhead cables and gantry, perform the whole project smoothly during 45 days.

Collaboration of GPLN Members SNS and Conti-Trans

GPLN member SNS International Transport from Turkey accomplishedly and achieved successfully a project delivery of two separate transformers, each weighing 75 tons and a dimensions of (L) 7,35m x (W) 2,50m x (H) 3,90m, cooperating together with esteemed GPLN partner CONTI-TRANS Speditionsgesellschaft mbH from Germany.

In addition to this, loading of the accessories and equipment belonging to the two transformers was also carried out and loaded into 9 different tilt trucks during the three days operation. A total of 105 pieces of accessories and transformer equipment was loaded and moved to consignee’s address within 6 days. The transformers were shipped as RO-RO from Pendik port which is located on the Asian side of Istanbul. After the transshipment arrived at Trieste port in Italy, customs procedures were fulfilled and both transformers were transferred into new lowbed trailers which arrived from Italy. Afterwards the lowbed trailers departed to the consignee’s address where they arrived safely.

Contrary to all obstacles encountered, SNS & CONTI-TRANS’ collaboration overcame them and solved all the problems with their long years of experience and dedication, and due to their timely correspondence, which was the key for a smooth communication between both partners. Based on confidence, speed, and finding solutions, the result of this collaboration was a huge success!

CHIREY ship cargo to Nigeria and Bangladesh

The first shipment by GPLN member CHIREY Global Logistics from China was a dredge boat from Tianjin to Lagos, Nigeria by heavy lift vessel.

Th total quantity was 1,000 FT, the dimension (LxWxH) 19m x 3.3m x 3.06m and the maximum weight 46 tons.

Furthermore, CHIREY PROJECTS shipped also trailers from Shanghai to Chattogram (Chittagong) in Bangladesh by a breakbulk vessel. Th total quantity was 860 FT, the dimension (LxWxH) 11m x 2.5m x 3.75m and the maximum weight 13 tons.

FOX Brasil Project Logistics handles 5 Transformers

Project Logistics, the overall performance of logistics service providers (LSPs) particularly, essentially depends on the extent of information sharing among stakeholders, mostly because information sharing can contribute to reducing the cost to the firms as well as the whole supply chain. The effective information sharing is considered an important aspect of supply chain management in addition to products and financial flow (Sahin & Robinson, 2002), or the appropriate integration of information sharing between suppliers and retailers enables effective decisions to deal with environmental uncertainty while reducing logistics costs and improving customer service levels (Kumar & Pugazhendhi, 2012).

Given the potential of information sharing to improve logistics performance, especially in developing countries such as Brazil, it is important to understand the customer needs, and explore what factors influence in a great deal planning. This is a methodology of GPLN member FOX Brasil Project Logistics: Since the nomination, we started our working in a planning of aligning, with a perfect information flow, providing a transparency and efficiency experience, avoiding mistakes, with focus in play down of extra costs.

By emphasizing information sharing quality in the logistic solution, we are delivering reliable characteristics and thinking about every detail, including the weather conditions for execution (this was the great challenge of this project). The transformers were manufactured in Brazil – Guarulhos City. Inaugurated in 1954, it is the Group’s first factory in Brazil. In this location are the areas of robotics, transformers and medium voltage products, panels, power substations and other products and systems for utilities and industries. The loaded trailers were moved approximately one hundred and thirty kilometers to the Substation of the final customer, where the engineer from our team, made the inspection and prepare an action plan to receive this equipment. For the heaviest transformer, the scope included a jack and slide operation to move the old transformer from its pad at the power station and the same operation for the new transformer. With the use of a reach forklift, FOX Brasil also loaded out and hauled the transformers accessories, lashing the entire load to the trailer.

The principle challenges in sliding the transformer were created by limited site access, and a live substation environment with energized electrical equipment in close proximity to the surrounding work area and overhead. Also, we face the challenge of transporting all these transformers during the Holiday Season, which in Brazil, the Legislation is super strict for the transit of heavy equipment. Besides that, it was necessary to stop the operation for several times and even days due to bad weather conditions, and thus, be able to have a safe operation, and avoid extra costs to the customer. Through an operation progress report, sent daily, all the steps were performed with excellence, and duly informed. Our team – 5 dedicated people: Service Quality and Customer Service, Engineer, Operation and Project Manager, received in the conclusion of the project a good evaluation from ABB Ltda, considered as great performance. Project details: Power Expansion Project

with 5 Transformers weighting between 134 to 204 tons and a dimension of (LxWxH) 8,40m x 3,60m x 4,81m and (LxWxH) 10,80m x 4,62m x 5,10m respectively, as well as 1340,00m³ / 400 tons of accessories. The scope of work was Logistic Solution, Engineer Planning, Complete management of the communication flow among stakeholders, Heavy lift road transportation, Discharge on base at the plant of the final customer, Domestic insurance coverage and Positioning on foundations and assembling works.

Collaboration between Megalift and Asia Imperial Cargo Logistics

GPLN member Megalift from Malaysia has been working with another member of GPLN, Asia Imperial Cargo Logistics from Shanghai, China, for several shipments from China to Malaysia. The import to Malaysia involved a variety of machines including Stamping Machines, Feeder and Straightener Machines. Especially the stamping machines were oversized with a weight of 85 tons and a dimension of (L) 6.179m x (W) 3.776m x (H) 4.285m and required the use of our multi-axle hydraulic trailers.

Asia Imperial Cargo Logistics took charge of the arrangement in China and the transportation of the freight to Port Klang, Malaysia. We then took over from the port and delivered the items from Port Klang to two different locations: Bangi in Selangor state and Batu Pahat in the state of Johor. The consignee has two plants in Malaysia to perform different precision works. This is a great example of a successful collaboration between two GPLN members. We will see a long-term partnership between Megalift and Asia Imperial as we expect more shipments to follow. Certainly, we are also excited to work with other members of GPLN in China and from other countries.