.

A Word From GPLN: Issue 74 / March-April 2020

If the Covid-19 outbreak is contained by the fourth quarter of 2020, demand growth for breakbulk and project cargo will stagnate over the next two years, according to consultancy Drewry. They expect multipurpose and heavy lift cargo demand growth to rise at an annual rate of just 0.3 percent until the end of 2021, as the longer-term economic fallout causes recessions in multiple countries.

The Covid-19 outbreak has virtually affected every industry. For the renewables sector, construction of wind and solar projects in China has slowed over the last few months due to the Covid-19 outbreak, hampering the return to work after the Lunar New Year holidays. However, recent reports suggest that turbine production is on the increase again in China. Europe is a major manufacturing hub for wind turbines but the European manufactures have been forced to close their facilities in Spain and Italy since mid-March. According to WindEurope, a total of 18 factories have been closed, including facilities of leading manufacturers like Siemens Gamesa, Vestas, Nordex and GE-owned LM Wind Power. Additionally, a number of onshore construction sites in Scotland have come to a standstill and Atlantique Offshore Energy has halted the construction of the electrical substation for the Saint-Nazaire offshore wind farm. Meanwhile, the recent lockdown in India required wind turbine and solar PV component manufacturers to close until mid-April.

Of all the unprecedented swings in financial markets since the Covid-19 pandemic broke out, none has been more significant than the recent collapse in a key segment of U.S. oil trading. The crude oil price fell for the first time below zero. That means that oil producers are now paying customers to take their stock! Or in other words: A barrel of oil is now cheaper than a coveted roll of toilet paper!

In the meantime, we have postponed our AGM in Casablanca from this year to May 15-17 in 2021 at the Parkhotel in Bremen/Germany, just ahead of Breakbulk Europe (May 18-20, 2021), so that our delegates can combine next year both events in the same city. All relevant details are published on our dedicated AGM page of our website. This is obviously subject that the world is back to normal by then.

As you know this year’s Breakbulk Europe has been also rescheduled and will now take place from September 29 to October 1, 2020. GPLN will exhibit at this event and has secured the same prime location in the main Hall 5 of Messe Bremen and still a few spaces are available for GPLN members who would like to join and share our stand. Right on the day Breakbulk Bremen starts in the evening, on September 29, we are organizing again our renowned Heavy Lift Maritime and Transport Seminar at the Parkhotel which is located within walking distance to the exhibition center. This technical course is also open for non GPLN members and offers a great opportunity to learn more about Heavy Lift Shipping and expand technical abilities and knowledge for project cargo business. More details are available on our website. Both our participation at the Breakbulk Expo and our Seminar are obviously subject that we’re back to normal conditions allowing us to travel and participate safely.

At the time of writing we are also planning to exhibit at Breakbulk Americas in Houston which was postponed from end of September to November 3-5, 2020. However, this year we will skip Breakbulk Asia in Shanghai which was rescheduled to August 3-4, 2020.

Stay safe and healthy!

Your GPLN Team

| New GPLN Members / March – April 2020 | ||

| Chile | Santiago | CLASQUIN CHILE SPA |

| China | Shenzhen | Fly Dragon International Transportation Co. |

BATI GROUP handles flat-rack project

GPLN member BATI’s project team recently handled flat-racks from Turkey to Oman. The flat-racks were loaded in Istanbul and delivered to the port of Ambarli outside Istanbul, where they were covered by a tarpaulin. The cargo was afterwards shipped from Ambarli port to Duqm port in central-eastern Oman. In another flat rack movement from Turkey to Oman, BATI shipped 8 flat racks from Izmir to Duqm. The cargo had different sizes and was lashed to flat racks, each of them weighing around 12 tons. BATI’s project team successfully coordinated and executed this task from home where all employees are presently socially isolated.

BATI GROUP ships boiler

GPLN member BATI would like to proudly announce the latest project executed by them. A 52 tons boiler was transported together with its accessories from Gunzenhausen (Bavaria) to Hamburg with a lowbed trailer. The boiler who had a dimension of (L) 9m x (W) 3m, was shrink-wrapped and delivered to the port where all items were loaded on to a breakbulk vessel from Hamburg to its destination in Tianjin, China. The total cargo volume was 250 CMB and was successfully handled by BATI GROUP.

Punto System handles tunneling project

With over 30 years shipping experience into construction equipment and building material sector, GPLN member Punto System from Italy was handling transportation for a large tunneling project in South America, involving 400 oversized pipes.

The first urgent lot for this project started involving 60 pipes, which were collected as loose items and lashed onto 30×20’FR OOG before shipping

Biggest single piece ever delivered to Africa

At the port of Bremerhaven, parts of a gantry crane with a length of 32 meters and a total weight of 48 tons were onboard of EUKOR’s Asian Trust bound for Mombasa, Kenya. This shipment was part of a large project for building a new grain terminal facility near Mombasa.

As many of us all know by now, to deliver heavy and out-of-gauge cargo without wheels we use special cargo handling equipment. For this project ex Bremerhaven to Mombasa, 80ft roll trailers, known as the longest of its kind that can cater cargo up to 24 meters long and 2.5 meters width, were used. Due to its size and shape being rather unusual, some people doubted if this could actually work.

But an excellent performance coupled with a close cooperation with all concerned parties from stevedores to ship’s crew and port & cargo operation managers made this shipment possible.

There are several factors we need to take into account when loading OOG cargo. For example, weather conditions, cargo handling equipment availability and cargo dimension to name a few. When given dimensions at the time of booking and actual size of the cargo upon delivery do not match, there goes the problem. This is why we do go through simulating and internal discussion with colleagues for successful stuffing prior to loading. For this time, as can be seen from the images on the below the center of gravity was pretty low and also the boom blocked up by wooden dunnage. This was a bit of challenge, said Capt. Jan Luenzmann, a travelling supercargo specialist in charge with over 16 years of experiences.

It’s probably the biggest single piece EUKOR ever delivered to Africa. Many highly recognized this shipment as a successful case, not only for how we handled the enormous size and shape of the cargo, but also for how all the concerned parties within the WW organization has put everything together by combining commercial and operational competences and experiences in an agile way.

“We chose EUKOR very naturally because we had already used their vessels on this project, which we have been handling for several years, and the MAFI transport on Roll-on Roll-off ships is perfectly suitable for static transport as well. Their teams are efficient and trained in exceptional transport,” said the customer from Paris.

Mr. Raphaël Roche, a Sales Support Officer at WW Ocean – the sales agent for EUKOR in Paris France added that “Our team has been working on this project since October last year. Our customer from Paris, one of the freight forwarders specialized in selected large projects, chose EUKOR because we have proven that we have all the assets through our organization to expand beyond our traditional market segment. Also, through a continuous communication with customer, along with coordination between colleagues from different functions, we were able to load the gantry crane arm and an extra parcel that accompanied the long arm successfully”

Super Cargo Service Group ships steel for FIFA WC 2022 Stadium

After the Covid-19 outbreak was declared a pandemic many flights and large events have been cancelled as countries and companies implement travel and working restrictions. Logistics were affected all over the world, with no exception of any country. In Vietnam, many flights were cancelled, and the air cargo capacity reduced by 75%, therefore inland traffic was much less compared to normal circumstances.

Despite this fact, GPLN member Super Cargo Transport, as well as Super Cargo Service Group, are all 100% in charge and just recently successfully shipped 1,045 tons of structural steel system from HCM in Vietnam to Hamad in Qatar for building a FIFA Football World Cup 2022 stadium. The volume was 161 packages and 12,991 CBM and the scope of work included also chartering, stevedoring and shipping.

In another move Super Cargo’s team has successfully managed a big bulk cargo shipment of steel billets from HCM in Vietnam to Batangas in the Philippine which had a volume of 7,995 PCS and 5,421.510 MTS.

PROTRANSER delivers a set of rudder

GPLN member PROTRANSER’s project team delivered a set of rudder by sea barge from Liaoning province in Northern China to Jiangsu province in Eastern-Central China. The dimension of the cargo was 10.3m x 9m x 2,3m and the weight 79 tons. The cargo was located in Lüshun district, Dalian city and the team picked up the cargo from the factory by trailer and delivered it to Lüshun port.

After chartering a sea barge the cargo was loaded load and moved to Dalian bonded port for customs clearance (for export and import). After finishing the import customs clearance, the barge was delivering the cargo to the nominated shipyard in Jiangsu province, which took around 4 days.

Allseas Global Logistics ships large catamaran

The Sierra Queen is a large capacity high-speed craft built in 1986 and has a dimension of 38m x 9.4m x 6m and a weight of 140 metric tonnes. This catamaran has sailed thousands of tourists and locals in the Freetown area of Sierra Leone for many years.

Allseas Global Logistics were asked to manage the move of this vessel from Freetown in Sierra Leone to its new home in Rhodes, Greece. As with any vessel charter, meticulous planning is key as the operation included the precise lifting of the vessel from and to the water at both its origin in Freetown and the destination in Rhodes. This meant communication was critical throughout the whole move, as any changes to the mother vessel schedule would need to be immediately relayed and managed to ensure the shipment went as smoothly as possible.

The Allseas Global Logistics team worked with the client and project partners in order to keep close lines of communication between all parties, managing the process at every stage of the move. This included the Port Agents and the Shipper to arrange the required Tug vessel to perfectly position the Sierra Queen for loading to the Mother Vessel.

Once lifted from the water, the Sierra Queen was lashed and secured to the deck ready for shipment. Focus then turned to the destination in Rhodes, similarly managing the process and close communication with the Port Agent and Tug vessel arrival team. The detailed planning and continued communication ensured the Sierra Queen safely reached its destination, into the waters of Greece, on-time and on-budget.

PT Energy Logistics teams up with Logistics International to ship drilling rig

GPLN member PT Energy Logistics teamed up with fellow GPLN member Logistics International to ship a drilling rig with its equipment to Indonesia with East Timor as a final destination. This rig will be the first one to operate in East Timor over the last 40 years in order to develop onshore oil and gas resources within the country with the first 5 wells expected to be drilled in 2020. The shipment consisted of 146 packages breakbulk and 12 containers for a total of 1,253 TS, 4,848 M3. Most of the packages were trucked from Oklahoma directly to Manchester Terminal in Houston, but some cargo was delivered first to Logistics International’s warehouse in Houston. Bill Durkin and his team arranged repacking and skidding as well as the export formalities. The Heavy lift vessel, MV BBC Asia, was chartered by PT Energy Logistics on behalf of their client, located in East Timor. Cargo was loaded during the first week of February and discharged in Kupang, East Indonesia, on 26th of March.

In order to avoid unnecessary storage and double handling costs, we arranged ship to ship operations and the cargo was discharged directly onto barges on transhipment basis with its final destination in East Timor. The discharging operations took 4 days to complete in difficult conditions. All the operations were supervised by Pt Energy Logistics’ representatives and were completed promptly, efficiently and safely. The cargo was received in perfect condition and PT Energy Logistics was congratulated for a perfectly executed job.

JSL Global WLL Qatar ships CO2 tanks

GPLN member JSL Global WLL (Qatar) shipped 2 x CO2 tanks for a European client who is serving the Qatar Power Plant-Umm Al Houl. Each tank had a dimension of 18m x 4.2 m x 3.5 meter and a weight of 45 MT. The challenges were: Shipment arrived on 26th March @ Hamad port during ongoing COVID 19 issue. Shipment was booked as Breakbulk on containerized vessel. Considering ongoing restriction from Qatar government and less working timing for all private/public entities, JSL has planned to take shipment on beams to avoid any unplanned delays at port or at consignee’s site. Engineering team checked technical drawings and we managed to source beams to handle this width cargo and planned to take direct delivery from vessel to multi axel trailer.

Shipment arrived on Wednesday late night and JSL team managed to get traffic department’s approval and escort permission on Thursday morning itself. As shipment was urgent for final site, JSL Global team arranged customs inspection and other formalities and took these 2xCO2 tanks out from port. But because of ongoing restriction for less working time for most government entities, Thursday night shipment could not be delivered to client site. For Friday/Saturday usual cases the Traffic Department permission is not feasible. Finally, JSL managed to get Police escort permission as special case for Sunday and managed to transport cargo to the power plant on Monday early morning. But because of heavy wind and less visibility on this morning shipment could not be offloaded using a crane.

But JSL planned from beginning all these exceptions and managed to offload cargo using beams/stools options and assisted client to ground cargo at laydown area. JSL Global Operation’s team coordinated this project from different countries + different sites/offices/home because of COVID 19, and JSL major team was also working from home as only a few persons of the operation team were present at Hamad port etc. “We @JSL Global would like to thank all concerned parties including Q-Terminal, Qatar Customs and Qatar Traffic department who supported this important project even during this challenging time.

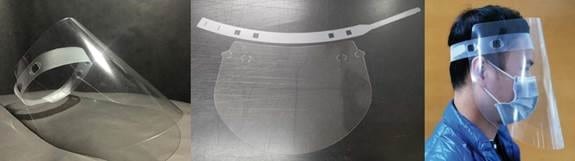

Face-shields to Italy

Due to an existing relationship with a Chinese exporter, who usually produces plastic packaging, GPLN member Lysander Shipping from Genoa in Italy has recently arranged a shipment of over half a million face-shields to be used in hospitals around Northern Italy. With the help of our Hong Kong partner, the Chinese exporter has managed to switch production from plastic packaging to plastic medical masks in an effort to assist in the fight against the Covid-19 pandemic. Lysander has been coordinating with the Italian government representatives and our Hong Kong partner, in order to ensure the first delivery of 750,000 face-shields which arrived over 5 large airfreight shipments during March and early April.

After careful discussion with the customs authorities we were able to give instructions to the importer on how to issue the documents in order to import the masks free of duties and benefit from a smooth and fast customs procedure, considering the exceptional circumstances and urgent nature of the cargo. The face-shields are used by hospital staff in the Lombardia region of Italy, an area with the highest registered cases in the world since the beginning of the pandemic. In addition to the 750,000 face-shields a shipment of 5 containers are currently on their way from Hong Kong, with even more face-shields. During this time of global emergency, where hospital staff in Italy and around the world are performing heroic acts in the fight against this terrible pandemic, we hope we can play a small part in the effort to fight it.

CHIREY Projects transports Railcars

CHIREY Projects, a GPLN member from China, recently transported a number of railcars from a Chinese factory to the end users. Cargo details: one unit had a dimension of 17,5m x 3.52m x 3.91m and a maximum weight of 73 tons. Products from the railcar industry is known very well by CHIREY Projects since they are involved in this business since the company was established 20 years ago. CHIREY Projects has handled all kinds of railcars products, and is able to provide full sets of services, including full supervision, inland transport, customs clearance, design hoisting tools, ocean shipping, surveys, and so on, therefore a one stop end to end services expert! CHIREY Projects focus on professional logistics solutions of the railcar industry from China to worldwide destinations by heavy lift / breakbulk / container vessels.

Shodesh Shipping handles mega shipment for power plant

Shodesh Shipping’s project team handled recently the biggest shipment so far for the Rooppur Nuclear Power Plant Project in Bangladesh. They are very proud to be the exclusive agent in Bangladesh for handling the mega shipments and have used a total of 9 barges to transport them by river, as well as 187 trucks/trailers/low bed to transport the cargo by road from Mongla port to the Rooppur NPP project site.

At the project site they have used one 300 tons crawler crane, another 250 tons crawler crane, and two 300 tons grove cranes for unloading the cargo to the jobsite. They have just shared a part of the cargo out of multiple hundred cargoes.

The cargo was shipped by Baltic Winter & BBC PERU (2) vessels from St. Petersburg, Russia to Mongla, Bangladesh with 307 packages, including HL, OD and general cargoes and a total weight of 3,038,000 kg.