A word from GPLN: Newsletter Issue 77 / Sep-Dec 2020

Dear Reader,

The Covid-19 pandemic has caused more disruption to the energy sector than any other event in recent history. For many producer economies and for oil and gas companies, declines in production from existing fields create a need for new upstream projects, even in rapid energy transitions. However, there are reasons to be positive. The International Energy Agency (IEA) said recently that solar is the new “king of the global electricity market” due to the relatively low investment cost involved. Offshore and onshore wind energy will continue to spread. Natural gas demand is set to recover quickly, as countries continue to switch away from coal. Interest in hydrogen, ammonia and synthetic fuels is widespread, and all should provide long-term opportunities for the heavy lift and project forwarding sector.

Analyst Wood Mackenzie suggests that the power generation sector in Asia Pacific could attract a lot of investments over the decade ending 2030, with an average of 170 GW of capacity added annually. Most is projected to be spent on solar and wind energy in the region. Indonesia’s government announced recently plans to decommission 69 coal-fired or coal/gas-fired plants, totalling over 11 GW, and replace them with renewable power generation facilities, as part of a drive to double the proportion of green electricity to 23 percent. It also aims to double its gas production over the next ten years, following the discovery of huge reserves at the Sakakemang Block in South Sumatra. While the archipelagos of Indonesia are stunning, that geography creates challenges for project transportation. Most of the government’s development projects, whether building new power plants, water treatment facilities, airports, seaports, railways or laying submarine cables, are focused on opening up remote Indonesian locations and new areas.

In hopeful news regarding the Covid-10 vaccine, BioNTech Chief Executive Ugur Sahin has recently said that deliveries of BioNTech-Pfizer Covid-19 vaccines could come as early as Christmas this year. “If all goes well, I could imagine that we gain approval (from US FDA) in the second half of December and start deliveries before Christmas, but really only if all goes positively,” he said. This comes after the drug maker Pfizer on Wednesday said that their coronavirus vaccine candidate has shown 95 per cent efficacy in the late-stage trial. In the meantime, Moderna has also announced that its Covid-19 vaccine was 94.5 per cent effective in preventing coronavirus.

Distributing an effective COVID-19 vaccine to the global population will likely be the greatest logistical challenge since World War II. Delivery by air, which will be challenging given the shortage of air cargo capacity, can only occur to airports certified to receive pharmaceuticals, and these airports can only handle so much product at a given time. The vaccines will then be transported to distributors for allocation to hospitals, pharmacies, and vaccination centres, which have yet to be established. Enhanced security will be required to prevent theft of the valuable products, and many will also require specialized low-temperature packaging and shipping conditions. Considering that most COVID-19 vaccines will require storage at standard refrigerator temperatures (shipping and long-term storage conditions at minus 20 degrees Celsius), except for the BioNTech-Pfizer Covid-19 vaccine which requires minus 70-80 degrees Celsius, this approach will need the development of novel solutions for establishing and maintaining low to very low temperatures in the entire chain of transportation and storage facilities all over the globe.

Our next year’s AGM is scheduled from May 15-17, 2021 at the Dorint Parkhotel in Bremen, just ahead of Breakbulk Europe, so that our delegates can combine both events in the same city. All relevant details about our annual conference are published on our dedicated AGM page of our website. This is obviously subject that the world is back to normal by then.

As this is our last newsletter for this year, we wish you all the best for 2021.

Stay safe and healthy!

Best regards,

Your GPLN team

| New GPLN Members / Sep – Dec 2020 | ||

| Bahrain | Manama | Console Shipping Services W.L.L. |

| Bangladesh | Dhaka | Conveyor Logistics Ltd. |

| Canada | Toronto | Nu-Era Logistics Inc. |

| Canada | Vancouver | Rohde & Liesenfeld Canada Inc. |

| China | Qingdao | Jit International Logistics Co., Ltd. |

| Serbia | Belgrade | Holleman Transport doo |

| Spain | Barcelona | International Project Cargo S.L. |

| Turkey | Mersin | CETA LOGISTICS & PROJECTS |

| UAE | Dubai | Alpha Projects & Logistics DMCC |

| Ukraine | Dnipro | Holleman Ukraine SLL |

Sparber Group ships Fishing Boat

GPLN member Sparber Lineas Maritima from Spain organized recently the shipment of a Spanish fishing boat from the port of Palamos in Spain on board of MV Ulm Veronica to the port of Luanda in Angola. This was an extremely interesting and challenging loading and stowing operation, starting with lashing under water. The dimension was 23m x 6.5m x 22.43m and the weight 60 tons.

Furthermore, they have also successfully completed the transportation of 12 water pumps from Madrid/Spain to Bangkok/Thailand, including the main body, engine and all accessories for a total of 250 tons and more than 800 CBM. The shipment dimension of the 4 pumps was 5.5 m in length, 3.56 m in width, 3.8 m in height and each of them had a weight of 20 tons.

Transformers for the “City of the 10th Ramadan”

Madinat al-Ashir min Ramadan, or as we say the “city of the 10th Ramadan”, was the destination for six Universal Transport trucks in July. Each of these was loaded with one transformer, which are intended for a power plant that is currently under construction. They are now stored on the construction site for three months until the foundation is completed. The 46-ton transformers were loaded at the port of Alexandria. A special crane with a weight of 250 tons was used for the safe loading and unloading process. Universal Transport’s experts took a total of six hours from the port to their destination, Egypt’s largest satellite city.

GPLN member Universal Transport from Germany has been represented also in Egypt with its own subsidiary since 2016. “Egypt continues to be an interesting market for us, with a lot of potential for expansion, especially in the industrial and plant construction, it is important to have experts on site who know the market, the processes, and local customs,” says Managing Director Holger Dechant.

MOHAB moves generators to Russia

GPLN member Agence Maritime Mohab from Tunisia performed the loading at job site, using two 110-ton Faune cranes with a lifting capacity of up to 160 tons. A special lowboy (17 meters long and 3 meters wide) was provided for the inland transport from Sousse to la Goulette port in Tunisia and was used within 2 days in a row. The related cargo was 2 generators with accessories. Each generator was 15m (L) by 3.4m (W) and 3.5m (H)

The loading area was Sousse in Tunisia and the destination port St. Petersbourg in Russia. The total weight of the cargo was 130 tons and the total volume 380 CBM.

Futhermore MOHAB is also a Tunisian freight forwarder who can offer a gateway to Libya and all Libyan airports, such such as Misurata, Tripoli, Benghazi etc. They have recenty successefully organized two full charters by plane with its principals BURAQ Airlines from Tunisia to Libya.

BURAQ AIR is the only airline that is capable to get the goods transported to all Libyan airports without exception (TIP – MJI – BEN etc.) Being an accredited freight forwarder in Tunisia and having its IATA & CASS license, MOHAB has been for over 40 years a great partner for local and international customers and agents.

FASTCO moves Giant Tanks

GPLN member Fastco from Oman transported successfully in October a heavy and oversized tank with an escort to Samail, Oman. This route from the coast to the country’s interior traverses the valley. Dimension of the cargo: 5,8m x 5,8m x 8,8m and weight: 13 tons.

PROTRANSER delivers seamless steel tube

GPLN member PROTRANSER from China delivered over 1000cbm and 22m long seamless steel tubes in one lot from Shanghai to Korea by Breakbulk vessel. They supervised the whole process from delivering cargo to port, discharging on yard, covering with tarpaulin to loading on the Breakbulk vessel. As a special request and according to the client’s requirement, Protranser’s team also supervised the discharging process at the destination port. With the professional service and taking the advantage of good relationship with all related partners, Protranser’s team handled once more OOG (Out Of Gauge) cargo successfully.

GWC appointed as Official Logistics Provider for FIFA World Cup Qatar 2022

GPLN member and Qatar-based GWC Logistics (Q.P.S.C.), a leader in supply chain solutions including warehousing, freight forwarding, commercial, fine art, and event logistics services, was announced as the first Regional Supporter and Official Logistics Provider for the FIFA World Cup Qatar 2022. As such, GWC will be the key operational supplier of logistics solutions for the FIFA World Cup Qatar 2022. GWC, which was already the National Supporter and Official Logistics Provider for the FIFA Club World Cup 2019, will build on this experience and draw on its robust network of contacts throughout the world to deliver logistics and supply chain services for the FIFA World Cup 2022.Speaking about the announcement, FIFA’s Chief Commercial Officer Simon Thomas said: “Logistics are critical to an event as large and complex as the FIFA World Cup, so having GWC on board as a Regional Supporter and the Official Logistics Provider for the tournament will provide FIFA and its Commercial Affiliates with crucial support and expertise in logistics and supply chain management, which will ensure a smooth and efficient delivery of the competition.”

GWC Chairman Sh. Abdulla bin Fahad bin Jassem bin labor Al-Thani said: “Today marks a landmark achievement in the history of GWC as we are entrusted to deliver the logistical requirements for the FIFA World Cup 2022, and today we become a trusted player in the journey towards 2022, proudly doing our part in actualising another milestone of Qatar’s vision. We enter this agreement with confidence that we will showcase the world-class sporting and logistics infrastructure that Qatar has developed over the years, while embodying the values of sportsmanship and encouraging active engagement of football enthusiasts and wider audiences.” GWC has a logistical infrastructure covering more than three million square metres, including the largest privately owned logistics hub in the region, along with a team of dedicated and innovative specialists and state-of-the-art IT systems. The FIFA World Cup Qatar 2022 will take place from 21 November until 18 December in eight stadiums around Qatar – three of which are already fully operational, with two more scheduled for completion by the end of the year. For the latest tournament news, visit FIFA.com/World Cup.

Polaris Projects completes several projects

GPLN member Polaris Shipping Agencies LLC (United Arab Emirates) project team completed several projects successfully amidst several difficulties due to the COVID 19 pandemic situations, as follows:

Polaris projects division has concluded a contract for demobilization of construction equipment’s which is being returned back to contractors’ yard in port Tianjin, China from their Iraq Project. Since the equipment’s are shipped in different lots as required by receivers in China for the convenience of refurbishing, Polaris has made arrangements to ship the units on carriers Mafi’s ex the port of Umm Qasr with interim storage at Jebel Ali storage yard and further cross loading on to flat racks and other special equipment’s as required for UAE / China leg.

Polaris’ scope also included, technical evaluation of equipment’s at Jebel Ali Storage yard by qualified inspectors for receivers to have an idea on the condition of equipment prior receiving at their yard in China which also was part of the contract. The first lot of 2 x side booms, 1 x excavator and compressors were successfully shipped with shipment arriving receivers base by third week of September 2020.

Furthermore, Polaris projects recently also concluded a project for a shipment of used plant and machinery for one of their close Kenyan clients who had procured assets from UAE. Polaris successfully completed the project with their scope not limited to shipping activities but also technical evaluation and repair of all acquired items to ensure that same met the functional requirements as per Kenyan standards. Polaris scope of activities covered survey and repair of each items by qualified surveyors and technicians to arrange for functional reports / Coordination with relevant authorities such as BV and QISJ to have relevant certificate of conformity, in line with Kenyan import requirements / Cost effecting evaluation for best shipping mode and arranging shipment in DV’s, Special equipment’s and as RORO keeping in line the deadline for shipment to arrive Kenya / Complete FOB operation including dismantling of equipment’s as required to accommodate on Container Vessels / Ocean Freight up to Free Arrival Port Mombasa. Finally, Polaris completed this shipment on 28 x 40’ DV’s, 5 x 40’ Flat Racks, 2 x 40’ Open Tops and self-propelled units on a RORO vessel to the full satisfaction of all involved and within the permitted time schedule.

Advantis Projects showcases expertise in Heavy Lift Equipment

As Sri Lanka looks to compete with a fast-moving world, it has embarked on several vital large-scale infrastructure development projects of national significance, which provides GPLN member Advantis Projects with an ideal opportunity to showcase its heavy-lift assets and expertise gathered throughout the years, instilling confidence in local capabilities. Advantis Projects, a subsidiary of Hayleys Advantis Limited, is renowned for serving clients worldwide with the right equipment for any job, whether it’s for a one-day lift or more complex operations like the installation of steel elevated highway. The company recently commissioned special 260-ton crawler cranes and the 250-ton all-terrain cranes for a vital national project. These cranes are best in class available in the market for precision installation and erection works in the region. They are easy to rig and de-rig and offers flexibility, hence minimising time. The specialised equipment is operated and supervised by experienced crane operators and engineers, respectively.

The company has trained and developed of its own technical staff to maintain and repair the equipment in-house, and works closely with global equipment manufacturers. Such capabilities of the company stand as a testament to its commitment towards the expansion of local heavy-lift capabilities. Our team worked with the client and decided to deploy 260-ton crawler cranes, 250-ton all-terrain cranes, 50-ton rough terrain crane, aerial platforms and boom trucks. The company is the first and only in the country to exhibit such technology and an array of equipment. According to the Director of Advantis Projects, Shadil Rizan, “Advantis Projects provides global expertise with localised solutions to serve the market in Sri Lanka. Along with our unmatched fleet of machinery, the company provides reliable logistics support from customs clearance to the transportation of project cargo to on-site storage and handling, seeing to the smooth progress of the project.” According to him, Advantis Projects is actively working in the power & energy, construction, water management, ports and highways sectors in Sri Lanka along with other key sectors.

Megalift shifts Mechanical Unloaders in Malaysia Industrial Port

It was a highly critical job for GPLN Megalift from Malaysia to shift two units of 31-m tall Mechanical Unloaders in an industrial port that is located along the Straits of Melaka, Malaysia. Not only did it require engineering expertise, we would not have successfully executed without a team of experienced personnel. While the traveling distance was not very far, the coastal setting posed a considerably high risk with strong and unpredictable winds. Given the height of the cargo, it was also challenging adjusting its centre of gravity. From jacking up the cargo, moving along the trajectory and jacking it down at its final position, we had to take intervals of pauses to ensure cargo stability and gushes of winds to pass. First cargo: Mechanical Unloader / Dimension: L12.00 m x W4.60 m x H31 m and weight: 253 tons. Second cargo: Pneumatic Bulk Crane Dimension: L7.60 m x W4.60 m x H31 m and weight: 135 tons.

Höegh provides RoRo solution for Sugar Mill Project and Rail Tamping Machine

With the opportunity to support a sugar mill project in Kenya, Höegh Autoliners India was ready to assist. The shipment consisted of transporting two high and heavy cargoes from two different loading ports, and the team were quick to provide an efficient one-stop RoRo solution. The customer, an Engineering, Procurement and Construction (EPC) contractor in India, handles various projects across the globe and the sugar industry is one of their large markets. The cargoes, a steam turbine and a surface condenser, were critical equipment for the Sugar Mill project, and coordinating their shipment was of the utmost importance. The steam turbine is 4.4 meters high and weighs 55.5 metric tons while the surface condenser has a height of 4.6 meters and weighs 48.5 metric tons. The common challenge with transporting high and heavy cargoes is its dimensions. When transporting project and other out-of-gauge cargoes, it is imperative that the correct measurements are provided so a suitable solution can be provided.

Another challenge was that the shipments also involved different ports of origin. The steam turbine would have to be transported from Kobe to Mombasa and the surface condenser shipped from Mumbai to Mombasa. Höegh Breakbulk Sales Manager in India Capt. Atuldutt Sharma shares, “Our breakbulk team in Japan and India coordinated with the manufacturers to get the technical details of each of the cargoes. We then provided an operational solution for the safe lashing and stowage in line with Höegh Autoliners’ stringent cargo quality standards.” Using Höegh’s 32 feet super-low trailers, which are only 0.47 meters high, the steam turbine and surface condenser fit perfectly on to the rolltrailers. The cargoes were safely rolled and loaded on board the vessels in Kobe and Mumbai respectively. Compared to other modes of transportation such as container or LoLo vessels, our RoRo solution offers a safer and more cost-efficient method. Capt. Atul continues, “By partnering with the customer and manufacturers closely, and through our operational capabilities of managing the project, we were able to provide a one-stop solution that assured the customer of safe and efficient transport, allowing them the flexibility to ship their cargo to Kenya from the comforts of their office in India. Capt. Atul concludes, “With the capabilities of Höegh Autoliners as a Project Cargo Carrier, we are able to offer reliable, safe and efficient ocean transport solutions for our customers across the globe.”

JSC DAKOTRANS ships large-size container bulk tanks

During the period from June to September 2020, GPLN member JSC DAKOTRANS from Russia performed the transportation of three large-size container bulk tanks from Russia to the port of Chennai in India. The cargo consisted of three containers with a total weight of 315.5 tons, and the dimensions were up to 22 meters for the length, the width of 4.59 meters, the height of 5.17 meters. The scope of work of JSC “DAKOTRANS” included the delivery of containers from the place of production in the Moscow region to the port of Beseda nearby Moscow, then delivery to the port of Bronka in St. Petersburg, transshipment in the port and delivery by sea to the port of Chennai in India.

Upon arrival at the port of Bronka, St. Petersburg, the containers were loaded onto the ship by harbor cranes for further transportation to the port of Chennai, India. The total distance between the ports was 8,120 nautical miles, which the bulk vessel covered in 47 days. For transportation of these containers, specialized equipment was used at each stage of the delivery process, both for movement by land and for loading and securing onto sea transport. For JSC DAKOTRANS the delivery of this cargo was one of the most interesting tasks, as it required considerable preparation time and precise planning of all details.

D.W. S&T handles break bulk shipment to Iraq

GPLN member D.W. S&T Inc. from Korea successfully performed a break bulk shipment from Korea to Iraq for the Al-Suwayrah Air Base Project during the COVID-19 pandemic. The cargo was 5.5m wide, 8.8m long and only 1.1m high, consisting of PB shield- and sliding doors and a total of 2199.50 CBM. The scope of work included proper exporting packing, in-land trucking to Masan port in Korea, port handling at Masan, ocean freight from Masan to Umm Qasr in Iraq, import clearance process under duty exempted by MOD (Ministry of Defense in Iraq) and overnight inland transportation by lowboy trailer. For smooth delivery to the site and to avoid also any damage of cargo and any incidents on the road, all items were moved by lowboy trailers, instead of using normal flat-bed trailers in order to deliver all cargo to the site very safely. The shipment was part of a long term contracted cargo deal for this project in Iraq and D.W. S&T handled so far over 2,000TEU for this project. The cargo handling included also containerized cargo, air-cargo, and breakbulk items under exempted duty privileges.

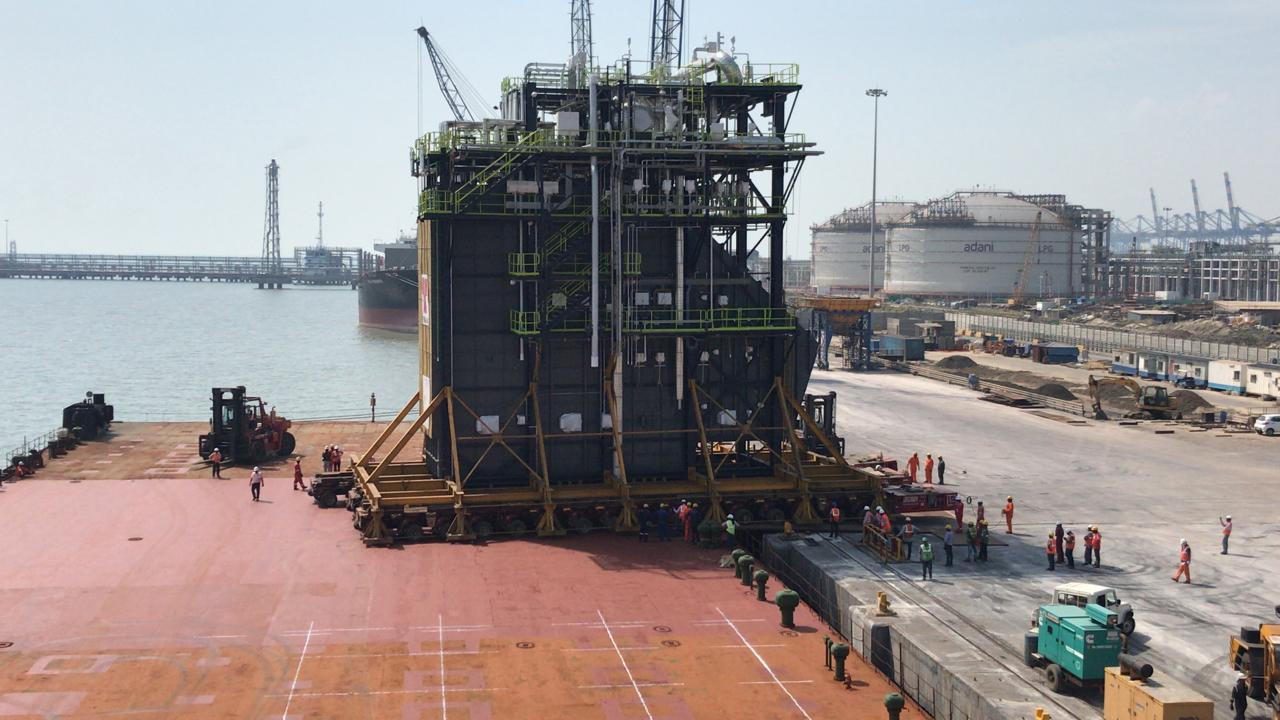

Lift & Shift India wins Overland Transport Provider of the Year 2020

GPLN member Lift and Shift India Pvt. Ltd, a leading Heavy Lift operator and Project Logistics company in India operating over seven decades, have achieved one more milestone by winning an International award – Heavy Lift Awards (HLPFI) 2020 for category ‘Overland Transport Provider of the Year’. The criteria and eligibility for the award was equipment-owning provider of overland transport services by road, rail or inland waterway that has demonstrated its commitment to the safe, efficient and innovative transport of heavy and oversize project cargoes. As per HLPFI, all the finalists in this category demonstrated exemplary handling of heavy and oversize project cargoes, but the judges were particularly impressed by project demonstrated by Lift & Shift India. The judges commented that Lift and Shift’s work required innovative solutions and engineering. Lift & Shift has demonstrated true teamwork and flexibility, with a well-engineered, planned and executed project particularly in consideration of the challenging environment and preparation required. Lift & Shift won the award for the delivery of the largest and heaviest boilers and heat recovery steam generator (HRSG) modules built in India for a refinery project in Nigeria. Lift & Shift India worked with the manufacturer, M/s. Thermax Limited, from the early stages of the project and provided a solution to move the cargoes from a yard in Mundra to Adani port. The complete cargo 26 HL / ODC / 15550 MT / 160000 FRT were exported on 3 roro ships and the heaviest equipment was 1200 MT.

Suvari Shipping delivers equipment for an agriculture factory

GPLN member Suvari Shipping from Turkey completed recently safely the delivery of equipment for an agriculture factory to one of the most effective agriculture companies in Russia. The journey started from Far East with 3 different COSCO vessels during a period of 3 months to fulfill the delivery time. The load consisted of 1650 metric tons /12.750 cubic meters, including 2 oversized items each with a length of 26 meters and a weight of 98 metric tons. With Suvari’s know-how, they arranged the best shipment method for the ocean vessels as they could not continue till Rostov due to Rostov’s port restrictions. Considering this fact, the contractor was choosing Constanta in Romania as a transit port, in order to make a transshipment.

After the cargo arrived in Constanta there was limited time to book the river type vessels to complete this shipment without any delay. Suvari’s experience project team arranged 3 special river type vessels with shallow draft which was suitable to enter Rostov water levels. Suvari’s operation team showed a high level of attendance for the 3 shipments handled from the mother vessel to the river vessel, and they were in full control to arrange also the cargo stowing and securing safely, as well as the required transit custom formalities. They were honored to be part of this operation and followed their duty with a strong team spirit.

ALPHA Projects & Logistics handle project shipments

GPLN member ALPHA Projects & Logistics are pleased to inform that we have continued our project shipments with our long-standing partners in both the Middle East and Asia. In mid-October we loaded 323.842 kgs of steel pipes in Antwerp which will reach final destination Balikpapan, Indonesia soon.

Another interesting project was a transhipping of an exchanger weighing 108.500 kgs with dimensions 1321 x 310 x 371 cm. It arrived first by barge via river from Chalon, France, to Antwerp, Belgium, where it was loaded on a MAFI trailer and shipped by RORO to Jeddah, Saudi Arabia.

Lastly, we also performed a project shipment of seven transformers to the power station in Brakwater, Namibia. The transformers were devanned at our warehouse/CFS and then transported by trucks from Walvis Bay to Brakwater by inland transportation in Namibia.

SNS International ships breakbulk cargo to Chile

GPLN member SNS International Transport company from Turkey has successfully completed the transportation of 19 open cargoes (breakbulk cargoes) and containers from Ankara to Mersin in Turkey and then shipped them to Puerto Angamos in Chile. We have transported parts for a complete shiploader, including main boom split only two parts, the dimensions of the first biggest part open cargo were 22.5 meters in length, 5.96 meters in width, and 5 meters in height, and weighed 80 tons. And the dimensions of the second part were 18.5 meters in length, 5.20 meters in width, 5 meters in height and weighed 45 tons. Our company has made a massive effort to professionally and effectively handle cargoes of such sizes, by utilizing a fleet of trucks that can support such dimensions.

SNS International deals with the best suppliers in Turkey providing a unique service that can meet various clients’ needs by satisfying and exceeding their expectations offering exceptional transport and logistic services, with quality, socially responsible, and professional standards.

STALOGISTIC’s project life doesn’t stop during COVID-19 pandemic

In September 2020 GPLN member STALOGISTIC from Russia has successfully completed a project for the delivery of equipment for the construction of a primary reforming furnace at the Shchekinoazot site. Route: China to Russia.

1) consolidate the entire cargo consignment (586 cargo items) from six different Chinese manufacturing plants at the port of departure, Zhangjiagang Gangxin Heavy Equipment Port.

2) inspect, measure and load the cargo on to the vessel, issue export documents.

3) charter a sea vessel for the delivery of 18,000 freight tons of cargo along the route Zhangjiagang port to St. Petersburg port.

4) reload the cargo onto auto transport for further delivery to the final destination.

5) issue the necessary transit documents.

The largest and heaviest cargo items were as follows: highest: 5.5m, widest: 5.56m, longest: 15,5m and heaviest: 123 tons

STA Projects’ team arranged this delivery of the construction of a primary reforming furnace from port of destination, Bronka (Russia) to the final destination (approx. 1000km faraway) by 188 units of special vehicles within a record 25 days.

The total project implementation period was 4 months from the start of consolidation to the unloading of the last cargo package and happened just during the quarantine period. This circumstance significantly complicated the operation performance. However, thanks to the efforts of the project team, everything was done efficiently and on time.

Star Shipping Pakistan backhaules Mechancial Beast Crane

GPLN member Star Shipping Pakistan has recently performed a tough reverse movement of a mechanical beast crane from Port Qasim to Thar Coal Project Site. It was a challenging job due to very short lead time and movement of the carbody of the main crane, weighing 72 tons. Multiple low beds & flatbeds trailers along with a heavy duty mobile hydraulic crane were utilized to transport this crane. Our scope of services included also the transportation from Port Qasim Site to the ETPL Block II Site, Tharparkar. There were few challenges during the transit such as road permissions, wild life and dry weather. Hence the job was done successfully and the crane delivered in safe and sound condition. Our operations team and all the other work force remained safe and healthy.

Cargo Way is setting up field hospitals in Peru

2020 has been a challenging year in every way, and the effects of the COVID-19 crisis have hit South America particularly hard. GPLN member Cargo Way, through its offices in Brazil and other places in South America, also played an important role in mitigating these consequences, being responsible for the logistics of setting up field hospitals in Peru on a temporary import basis. There were 4 hospitals, with 250 ICU beds, set up in the Peruvian Andes mountain range, in Juliaca, Puno and Cuzco cities. For this urgent operation, the company had to charter one full B747 Freighter and two B737 Airliners to meet the challenging deadline required by the Peruvian government.

Six extra regular flights were also used to move the remaining material for the hospitals. “It was an intercompany operation, where we mobilized staff from the offices of Cargo Way Brazil, Peru, Uruguay, Argentina and Chile. We were responsible for 100% of the operation’s logistics, from preparation and packaging, customs clearance, international flights and final delivery to the Andes mountain range region. We had team members at all stages, following each truck and each flight”, Rodrigo Picolli, Director of Cargo Way, said. There were 250 tons of air cargo shipped from Brazil to Peru. At the destination, temporary imports were cleared in less than 12 hours and loaded onto 16 trucks to travel 2000 km, climbing 4000 m, to the cities where the hospitals were set up. “It was all very time-sensitive but ended up being very rewarding. Cargo Way Peru even carried out the first import in the history of Juliaca airport. We were pleased to take part in this project”, Frederico Canquerini, Commercial Manager of Caro Way, said.

Today, patients are being treated in high-quality facilities, while Cargo Way is already preparing the logistics for the return of the materials at the end of the crisis.

The Freight Co engineers rolling stock move from France to Singapore

GPLN member The Freight Co., Ltd. from Bangkok, Thailand, has engineered a highly unusual move during the Covid-19 pandemic. It all started with a call in the middle of March from a friend in Switzerland to The Freight Co’s founder in Bangkok. “I have a friend in Singapore that needs help shipping 4 unit rolling stock from France to Singapore. Can you help?” After a phone call to the friend in Singapore it turned out that of 4 unit rolling stock 2 of them were considered natural treasure and another one national heritage. The 4 unit were supposed to go to Singapore for an exhibition.

Initially the 4 unit were supposed to be shipped in April. At the beginning the client only asked for help with the shipment from Antwerp to Singapore. Fellow GPLN member in Antwerp, Didier Wirtz from Wirtz Shipping & Co NV helped to get the necessary pricing from a Ro/Ro carrier. However, due to the Covid-19 issue the shipment got delayed and delayed. Throughout the summer months The Freight Co kept in constant contact with the client.

During this period, it transpired that the client was extremely dissatisfied with the information or rather lack thereof by the chosen contractor. The scope included loading at two different places in France and transport by road and river vessel to Antwerp. A decision was made to also push for the local scope ex works to the port of Antwerp. A technical concept was proposed that highly impressed the client in Singapore and their well-connected backers in France. At that moment The Freight Co decided to go for all out. Another push was made for the local scope in Singapore which includes delivery to the site including unloading. Eventually, the client decided to hand the entire job to The Freight Co and their assembled team.

Sometime in September the green light was given. The cargo was inspected together with the cargo owner, a method statement including lifting, transport, etc. was established and road permits were secured. Meanwhile the Ro/Ro vessel was booked. All cargo arrived Antwerp safely, part on the road and part on the road combined with river vessel.

At the time of writing the cargo is well on the way to Singapore and on the way to the exhibition which will open in December. Even though the job did not touch Thailand’s soil or any of the key players is based in Thailand, thanks to perseverance The Freight Co managed to secure a job that seemed to be well under control of the competition. And with perseverance it ended up getting the entire job not only the ocean freight as was initially the client’s idea. Lesson of the day: Never ever give up!