A word from GPLN: Newsletter Issue 79 / Mar-Apr 2021

Last month we all watched with concern the incident with Ever Given, an ultra large containership that was stuck in the Suez Canal for around six days, blocking one of the busiest shipping lanes in the world. This has created a traffic jam of more than 400 vessels which were left waiting at either end of the canal when the 400m-long Ever Given became wedged across it on March 23, 2021. In the meantime, the ship was formally arrested on April 13 by Egypt’s Authority over non-payment of claims of around USD 916 million. They didn’t explain where this amount comes from, nor have they provided a breakdown of expenses. It could include paying for lost USD 95 million in transit fees while the Ever Given blocked the Suez Canal, 2 dredger ships, 11 tug boats of varying sizes, wages of 800 Egyptian workers who operated around the clock to free the ship, damage to the canal and other miscellaneous equipment used to free the ship, such as excavators etc. We leave it to you to make your own opinion if this huge amount of almost USD 1 billion is justified. Furthermore, we think that the Egyptian Authority resolved this problem quite efficient within 6 days, which was faster than diverting a vessel and go around the horn of Africa, which adds an additional seven to nine days to a trip. Taiwan’s Evergreen Marine Corp., operator of the containership whose thousands of containers are stranded on it, is exploring now the possibility of transferring the cargo to another ship. This would enable the release of millions of dollars’ worth of goods, which are meant to be delivered all over Northern Europe.

In better news, the strong wind energy market, recovery of the dry bulk market, positive oil price development etc. contribute to the flourishing demand for multipurpose vessels. The charter rates have increased around 18% more than this time last year and have made a remarkable recovery since their low-point in June last year. Following the initial decline in demand as a result of the Covid-19 pandemic, the charter rates fell to a low. Since then, the charter rates climbed back up steadily until December, after which the increase accelerated driven by generally high demand and capacity issues in the container segment. Some project carriers even posted pictures on social media of their heavy-lift vessels fully loaded with containers.

According to the Global Wind Energy Council (GWEC) wind energy had a record setting year in 2020. Undeterred by the coronavirus pandemic, installations grew 59 percent year-on-year compared to the previous year. Leading the charge was China, which broke the world record for most wind power capacity installed in a single year with 52 GW of new capacity. Asia Pacific as a whole is increasingly driving the global wind energy industry’s growth, with the region accounting for 60 percent of all new wind power capacity in 2020. In addition to China, Australia, Japan, and Sri Lanka all had record years for new wind power installations in 2020 and strong demand is also continuing in 2021.

As you may know, Breakbulk Europe event in Bremen was moved from May this year to a new venue in Rotterdam from May 17-19, 2022. GPLN will exhibit at this event and has secured a prime location in the main hall. This is obviously subject that the world is back to normal by then.

In regards to our AGM in 2021 which is scheduled from September 18-20, 2021 at the Dorint Park Hotel in Bremen, we are carefully monitoring the situation and are also regularly in touch with our GPLN members in Germany. Furthermore, we are now evaluating an alternative location in Asia in the first quarter of 2022 as a back-up.

Please stay safe and healthy!

Your GPLN Team

| New GPLN Members / March – April 2021 | ||

| Finland | Turku | CF&S Finland Oy |

| Germany | Stuttgart | Transmaritim international GmbH |

| India | Mumbai | TEAMGLOBAL Logistics Pvt. Ltd. |

| Kenya | Nairobi | Afriasia International Shipping & Logistics Limited |

PNI Logistics arrange shipments for Qatar airport and Nigeria power project

PNI Logistics handled the transportation of 2650 freight tons of steel structures of various sizes, with a total of 460 pieces from UAE and loaded them also on to a barge. The scope included coordination with the supplier in UAE to make sure that the material was bundled and lashed for safe transit, including coordination for the transportation to the port for the cargo to be loaded on a 5000 DWT barge. We had to ensure that the cargo was coordinated as per loading sequence and also delivered as part cargo on direct delivery basis, as well as part cargo on indirect delivery to ensure continuous operational efficiency.

Documentation, in transit and port acceptances and permissions were also arranged from our end. The PNI crew was there at the site working in multiple shifts to oversee the operation and ensure that all the cargo was loaded in the agreed time frames without interruptions. The shipment was very time critical for the Qatar airport concourse project and given all the challenges like reduced work hours due to Ramadan and other operational delays, it was a very closely monitored coordination from our side to ensure success of the project move which we executed efficiently.

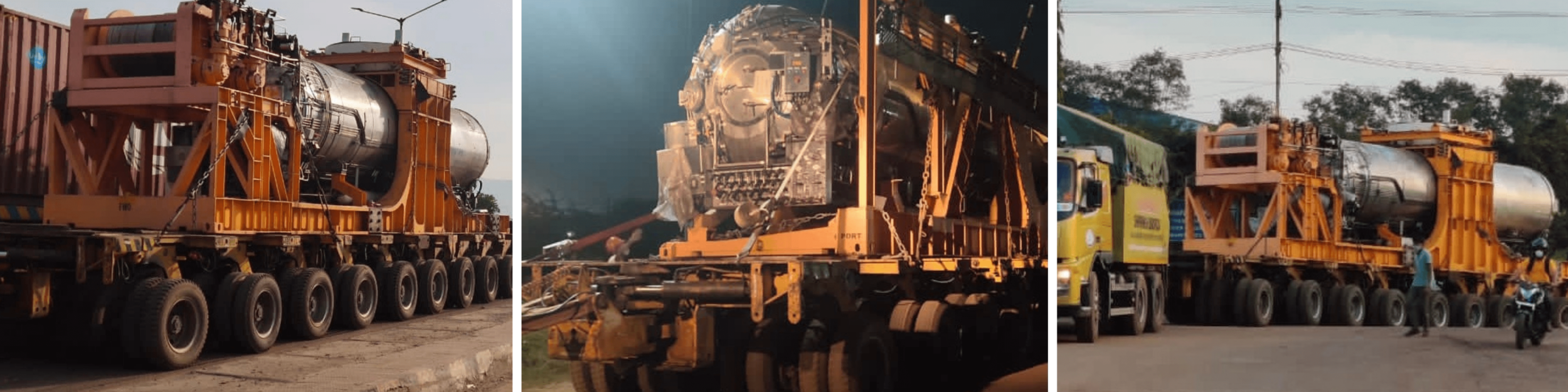

In another task PNI arranged the transportation of 3,300 freight tons of used gas power plant which was moved from UAE to Nigeria. This consisted of 2 units of gas turbines weighing 127 tons each and other accessories totally 62 packages. Our scope included coordination of transportation from UAE yard to port including all transit and port permissions. All port related acceptances and permissions were arranged by us. The PNI crew was available at the port to supervise and assist in the operations. We chartered a break bulk vessel to move the cargo from UAE port up to Onne port in Nigeria. Coordination with vessel owner and tracking the vessel to ensure the time line was met and clients were updated on the vessel position real time basis. Final coordination with the end client in Nigeria and multiple online joint meetings to ensure all parties concerned with the shipment were updated on the delivery schedules.

Universal transport locomotives from Kassel to New Jersey

A total of 25 locomotives from a plant in Kassel will serve rail lines in New Jersey, USA soon. The first special locomotive successfully reached its destination mid-January this year. The transport of the locomotives from the plant in North Hesse via the Port of Hamburg to the USA is in the hands of the Universal Transport Group and its subsidiaries.

The project forwarder, GPLN member Universal Transport’s sister company, Züst & Bachmeier, was responsible for organizing and handling the transport, including unloading, in the US port. Universal Transport took care of all necessary work up to the seaport. The implementation of all necessary measures to prepare the route as well as the transport escort was carried out by the StB Verkehrstechnik.

The planning and preparation of this complex transport took over a year. For example, the transport to the seaport had to take place on the road, because the locomotive is not designed for use on German rail networks. On one hand it is too heavy in terms of axle load, on the other hand the built-in train technology is not permitted here in Germany.

For the road transport of the locomotive, however, many traffic control measures were necessary along the 360 kilometers to Hamburg, traffic signs were dismantled, trees had to be cut, roadway plates were laid out and curve radiuses expanded. The height of the transport – the locomotive plus the low-loader measured an impressive 4.50 meters – posed a major challenge. When crossing bridges, there was often only a few centimeters left. After four nights, the 90-ton locomotive arrived in Hamburg. Here it was finished off with its bogies. The cargo with a total weight of now 130 tons was then loaded by Ro / Ro ship to the port in the USA, where it was finally transferred directly onto the tracks of the American rail operator.

Total Movements ship transformers to USA

GPLN member Total Movements from India executed this door-to-door delivery of 2 x 150MT transformers from ex-works India to the final site in the USA, in the middle of heavy rain and Covid induced disruptions. It was a complete end-to-end scope that we successfully executed with the help of our reliable partners. Our scope included local transport in India, customs clearances, ocean transport from India to the USA, custom clearances in the USA, and final transportation to the site. While the shipment was fraught with challenges, our team managed the delivery with advance planning with ease. The consignment was delivered safely and timely to the site to the satisfaction of the customer. Total Movements thanks all its partners who were a part of this successful execution. A special thanks to Jumbo Maritime for carrying this consignment on their prestigious vessel MV Jumbo Kinetic and to Wheel & Time for their support.

CKB complete mobilization of Caterpillars (CAT) 777E

GPLN member PT Cipta Krida Bahari (CKB Group) from Indonesia, a member of PT ABM Investama Tbk (ABM), has completed a project logistics service from PT Trakindo Utama to mobilized 18 units of Caterpillar (CAT) 777E from CKB Group Jakarta Mega Hub, Indonesia. The destination of 15 units was Durban in South Africa and another 3 units Tema in Ghana.

CAT 777E is an Off High Way Truck model that is used to transport loose material and mineral/coal materials in the construction and mining sites. The CAT 777E has an empty weight of 65 tons, with a total load weight of 100-105 tons.

A prudent survey, operating plan analysis, routes and selection of the right type of transportation are key factors for successful delivery, which means meeting the customer’s expectation with CKB Group solutions. The project was challenged by Indonesia’s geographic and inadequate infrastructure; thus, the company plays an important role in restoring the necessary infrastructure such as strengthening local bridges so it could be crossed by the project shipment transportation. Nevertheless, with CKB Group vast experience in handling this kind of project, the shipment of these cargoes was delivered on time and safely.

Global Shipping Services handle Minster Presses

GPLN member Global Shipping Services from USA moved recently 22 pieces of a DAC 165 Minster Press for cupping and its accessories to Vietnam. Shipper sent Presses and its accessories to Baltimore for packing and crating. The shipment was time sensitive and had to depart USA before end of March.

The original plan was to move the cargo from Baltimore to Vietnam but due to the width of the Breakbulk pieces, equipment shortages in Baltimore and time sensitive material, we had to go via NY/NJ. Summary of cargo:

1 Breakbulk Crate – 212 x 186 x 96 – 147,000 LBS / 2 OOG Crates on 1 x 40’FR – 160 x 96 x 119 inches – 17,703 lbs. and 224 x 81 x 120 inches – 22,410 LBS / 19 smaller crates in gauge on 2 x 40’HC. Breakbulk was moved on a 13-axle truck from Baltimore to Elizabeth Port for a live load alongside vessel. 2 OOG crates were moved loose to trans load into 1 x 40’FR in Newark, NJ and then to Port Elizabeth.

2 x 40’HC were loaded directly from packer in Baltimore and moved directly to Port Elizabeth. From there all 22 pieces were loaded safely and on time on the CMA CGM Thalassa on direct route to Vung Tau in Vietnam.

Greenroad moves transformers to Ethiopia

GPLN member Greenroad International Logistics from China has successfully completed the transportation of 4 transformers from Shanghai, China to Oromia, Ethiopia. They were safely and securely loading a total of 130 tons cargoes from the vessel to the truck and by ship cranes at Djibouti port.

When the rainy season arrives in Ethiopia, it is almost impossible to organize and perform the transportation with minimal expense because of the slippery road, hot weather, steep hills and tire bursts due to abnormal running. Nevertheless, for Greenroad, the reason why we are an excellent project logistics agent is that no matter how big the difficulty is, it will be regarded as a challenge that can be overcome. To make the movement as efficient and safe as possible, an armed escort was essential for our high valued cargo of precious customers, besides multiple other safeguarding procedures.

SARR Freights executes a defense contract to Southern India

SARR Freights has successfully completed another turnkey turnkey project for ODC Cargo. Four packages, weighing 100 MT each, weretransport – ed using hydraulic axles in Southern India. The cargo was successfully delivered to Vishakapat- nam (port city and industrial center in the Indian state of Andhra Pradesh, on the Bay of Bengal), and the total distance covered was 700 km. SARR Freights provides clients with multimodal freight forwarding (sea, air, rail & road) and freight management solutions across the globe.

Megalift handle PLEM for offshore oil & gas project

Malaysia is one of the key oil and gas producers in the Asia-Pacific region, and it is therefore natural that oil and gas is a major industry that we service. For many years since the establishment in the 1980s, GPN member Megalift has been a trusted logistics partner for numerous international oil and gas players both within and outside of Malaysia.

A lot of what is used in oil and gas, whether onshore or offshore, are over-dimensional cargoes that involve high-risk handling with a considerable degree of engineering expertise. For some projects, the methods of delivery can be unique or even unprecedented. Thanks to our vast experience, we take pride in what have done and are always excited in exploring new possibilities for our clients.

Ushering into the year 2021, we are glad to share a loadout job that we performed for a new client. Apart from the PLEM (Pipeline End Manifold) that we rolled out using our multi-axle hydraulic trailers, there were also some pipe spools of various sizes and weight and smaller items to be delivered along to the offshore site using a barge. Dimension of cargo: L19.80 m x W16.60 m x H5.70 m / Weight: 102 tons

First carbon neutral voyage for Höegh Autoliners

On 19th March 2021, Höegh Autoliners accelerated its decarbonisation efforts successfully completing its first carbon neutral voyage from Europe to South Africa. During this voyage the New Horizon vessel Höegh Trigger ran on advanced biofuels meeting the highest sustainability standards. The successful trial voyage showed that biofuel is a viable choice for vessels in the fleet.

Höegh Autoliners is working closely with customers and partners in reducing its carbon footprint and supporting customers in decarbonising their logistics supply chain. Using advanced biofuels to run existing fleets has a strong potential to significantly reduce emissions today, while new ship technologies evolve.

Andreas Enger, CEO at Höegh Autoliners said, “We are committed to leading the way towards a zero emissions future. The success of this trial voyage demonstrates that with the use of alternative fuels like biofuel, we can contribute to significant steps towards decarbonisation in the maritime transportation industry. Our company and customers have high ambitions to combat climate change, and we are committed to delivering on that.”

Hear from Andreas Enger: GoodFuels’ biofuel was chosen for the test run as it’s virtually free of sulphur oxides and reduces the vessel’s carbon emissions by up to 90%. The remaining emissions generated were offset through certificates from Gold Standard, to make the voyage truly carbon neutral.

Isabel Welten, Chief Commercial Officer at GoodFuels, says, “We are proud to supply our truly sustainable biofuels. Working with shipping operators like Höegh Autoliners, we contribute to making ocean transport more sustainable and together play an essential role in reducing CO2 emissions in the maritime industry.

Learn more about the voyage:

Höegh Autoliners operates some of the greenest and largest PCTC vessels in the world: The New Horizon series can transport up to 8500 car equivalent units and were designed to minimise its impact on the environment. The vessels are equipped with the latest fuel-saving technologies, reducing CO2 emissions per car equivalent unit by 50% compared with standard car carriers.

A commitment to sustainable development:

Höegh Autoliners aims to contribute to sustainable development by operating as a socially responsible shipping company; actively integrating social and environmental concerns in business operations. As a patron of the UN Global Compact Action platform for sustainable ocean business, Höegh Autoliners is committed to conducting business in a safe, responsible and transparent manner. Sustainability activities are focusing on reducing the environmental footprint, protecting life below the sea and being a responsible business partner as well as a safe and inclusive workplace.

To support a more sustainable maritime industry, Höegh Autoliners works with organisations that drive sustainable development initiatives: Höegh Autoliners is a member of Clean Cargo. This business leadership initiative is dedicated to reducing the environmental impacts of global goods transportation, promoting responsible shipping, supporting clean oceans, healthy port communities and global climate goals. Höegh Autoliners is furthermore one of the founding members of the Trident Alliance, a coalition of shipping owners and operators who share a common interest in robust enforcement of maritime Sulphur regulations.

JSL Global handle steel structure for FIFA World Cup 2022 stadium

JSL Global Qatar & JSL Global Oman, both GPLN members, wanted to share that this project was most challenging- not because of dimension/weight or its route. But it was extremely demanding because it was handled at time when 9 JSL team members were Covid positive, including Mr. Rakesh Barai (Project Manager). This was a tough task for the whole JSL team to manage the office cum port operation in such a scenario. But Mr. Barai performed his responsibility so well by continuously coordinating all tasks with the JSL port operations team.

JSL Global Qatar was proud to handle this prestigious job, moving 490 CBM of heavy steel structures for the FIFA World Cup 2022 stadium. The shipment was arranged with a Breakbulk vessel ex Lianyungang Port in China and JSL Global handled it at Hamad Port in Qatar on indirect delivery, using port MAFI trailers & heavy low bed trailers. As the shipment was for one of the FIFA stadiums and considering ongoing work and site restrictions in receiving the cargo, it required immense planning between several parties including customs, port authorities, crane operators, traffic department, stadium authorities etc.

Lift & Shift delivers critical equipment for Paradip Refinery

GPLN member Lift and Shift India Pvt. Ltd. (LSPL), a leading Heavy-lift operator and Project Logistics company in India operating over 7 decades, have delivered another milestone by transporting safely 15 Heavy-lift & Over-Dimensional equipment from L&T Hazira for Indian Oil Corporation Ltd (IOCL), Paradip Refinery, one of prestigious projects of Government of India. M/s. Larsen & Toubro Hydrocarbon Engineering (LTHE) was the EPC company for the project and was awarded the contract for expansion of Mono Ethylene Glycol (MEG) plant and Ethylene Recovery unit (ERU) which included critical Heavy lift & ODC equipment from their yard in Hazira, Gujarat. Lift & Shift India was contracted by All Cargo Logistics Ltd for movement of 15 Heavy lift & ODC equipment from the fabrication facility in Hazira to Adani Hazira Port.

The cargo was shipped in two lots which involved Land and Marine transport using LSPL 250 class barge in 3 voyages from Larsen & Toubro Jetty to Adani Port Hazira. The critical and challenging equipment was transporting of the EO Reactor weighing 1200 MT and 2 Columns of 100 m length. The length of the 2 columns required the RORO jetty at L&T Hazira facility to be modified and levelled to meet “zero” degree elevation against the actual jetty which is inclined and suited shorter equipment. The EO Reactor was transported on 3 side by side axles using a total 66 SPMT axles. The Barge AF 250 loaded 2 Nos 100 m columns were flagged off by Mr. Dharmendra Pradhan, the cabinet minister for Petroleum & Natural Gas in the government of India. Lift & Shift’s expertise team was involved in meticulous planning from beginning to optimise the road and marine movement from Larsen & Toubro fabrication facility to Hazira port which is one of the keys for successful execution of the project.

PROTRANSER handles multiple shipments since beginning of the year

GPLN member PROTRANSER’s team delivered 2 sets of transformers from Turkey directly to Taiwan (not via China mainland). The weight and dimension of each main body was 52 tons and 7300x2900x2900mm.

Actually, we have started to communicate with our partner in Turkey since the end of Sep.2020, and meanwhile, keep close contact with our client, to check the possibility of different options, such as port of loading which might be related with the shipping schedule, port of discharging which might affect import customs clearance issue, BBK on container vessel or Ro/Ro, and so on. Finally, we were choosing the solution of BBK on container vessel, which was the suitable one at the time.

In another shipment PROTRANSER shipped a tank to door in France for an energy project. The weight and dimension of the tank were 28,000 kgs and 10.45m x 3.90m x 4.10m. Our work scope included: pick up of cargo, transport on container vessel (breakbulk way) from Shanghai to FOS and delivery to door.

Furthermore, PROTRANSER handled a set of high value stainless steel sculptures exhibits from Wuhan, Hubei province to New York by sea. The value of sculpture was nearly 2 million USD. The cargo was located in downtown Wuhan city, so we had to apply for permission for the truck to enter downtown to pick up them in a specify time period. We faced also another challenge due to the packaging of the goods which were nearly 2 meters height, and the limitation of the site. It was not possible to use mechanical operations to load the truck, and only manual loading could be used. During operation process of stuffing, forklift operator and workers coordinated with each other to push cargo into container slowly and carefully. And we arranged staff to supervise the whole process in order to make sure everything went well. After lashing properly, we delivered the precious cargo to New York by sea.

Besides other moves, such as 14,000 CBM cargo for a cement plant in Africa, 700+ CBM cargo from Switzerland and 1400+ CBM “door to port” from France to Hong Kong, 1000 tons cargo from Shanghai to a jobsite in Pakistan, and 1000+ CBM Heat Treatment equipment from Shanghai to Jakarta, PROTRANSER was honored to deliver a famous passenger car, Hongqi H9, to Dubai by air. The gross weight and dimension of the car was 1995 kgs and 5,137m x 1,904m x 1,493mm. Work scope included: pick up car in the factory in Changchun city, Jilin province, North China, delivery from Beijing to Dubai by air and transport to 4S store. Hongqi is a famous brand in China, the first Hongqi car was built in 1958 and chosen as official car for China’s major celebrations and events. Today, Hongqi L series limousine has also been chosen as official car for China’s major celebrations and events. For Hongqi H9, this is the first time to enter the market in Dubai. We delivered the car safely and on time to help our client to promote and expand the market.

PROTRANSER shipped also 64 different kinds of vehicles from China to the Democratic Republic of the Congo (DRC). These vehicles included dump trucks, fuel trucks and sprinkling trucks. All vehicles were delivered in 3 lots to Dar es Salaam port in Tanzania, 1 lot from Lianyungang port and other 2 lots from Shanghai port. Our work scope was from collecting cargo at port, chartering breakbulk vessel from China to Africa and arranging local drivers to drive all vehicles to jobsite in DRC after discharging.

Polaris Shipping handle several projects

The project team of GPLN member Polaris Shipping Agencies LLC (United Arab Emirates) recently completed several project shipments successfully. Details on a few of our completed jobs are listed below:

Shipment of Hydro Hammer on Steel Cradles to Singapore:

Polaris projects was appointed as project partner in UAE for by one of our close associates in Singapore for shipment of 1 x S800 Hydro Hammer on steel cradles weighing approx. 90 MT with shipping dimensions of 14.50×2.20×2.50 Meters (Length x Width x Height). In order for clients to have the competitive freight solutions, subject heavy lift was carefully planned to be transported out from shippers closed ware house using suitable gantry crane to Polaris nominated customs bonded storage yard in Jebel Ali Free Zone and transferred to carrier’s heavy duty MAFI for shipment to final destination on RORO tonnage. The entire operation was carried out under supervision of third-party independent surveyors under their strict quality control to ensure that the operation is line with respective guidelines issued by clients.

Shipment of Bird Cages to Port Casablanca, Morocco – 150 x 40’ High Cube: Polaris Projects was called upon last moment by a reputed semi-governmental organization for shipment of steel structures for Bird Cages from UAE suppliers’ yard to Port Casablanca, Morocco. As per the contract, Polaris Projects was responsible for choosing the carriers, arranging for suitable handling equipment’s for grounding of high cubes, assistance for stuffing & lashing, all other related FOB operations and ocean freight up to Port Casablanca, Morocco. Forecasting the restrictions due to Covid 19 and also reduced working hours during the holy month of Ramadan, Polaris Projects team managed to complete the operation in record time with satisfaction of all concerned.

Project contract for Shipment of Mercedes-Benz trucks ex Kuwait to Antwerp: Polaris has received an interesting order to handle shipment of Mercedes-Benz trucks arriving ex Kuwait by road for onward movement to Europe via Port Antwerp. Being UAE Sea Ports ideally located to handle any transhipment cargo with choice of several Break Bulk, container and RORO options, Polaris Projects are fully geared to handle transhipment cargo from/to any GCC states. Our Services includes positioning of suitable trucks at any GCC locations, lodging of necessary transit deposits at respective transit border points with related customs documentations to ensure that transit cargo is connected to on carrying vessels with no delays. The first lot of 6 x Mercedes-Benz trucks has arrived Port Jebel Ali and have been connected to port Antwerp as scheduled, followed with several lots.

Star Shipping coordinates various shipments

GPLN member Star Shipping from Pakistan was involved in various projects during the first quarter of 2021. Transportation makes up a third of the world’s movement of goods and therefore forms a significant part of our work at Star Shipping. Although transportation modes include transport by air & sea, our focus here is on the road products specifically, including the movement of Heavy Over Dimensional cargo. Efficient transport is critical to economic development, and our focus is on providing solutions for processes domestically. Below are details of some of our projects: Commodity: Petroleum Project Cargo / Volume: 4x 50 tons with accessories / Dimension in m (L/W/H): 18.22 x 6.09 x 6.09 / Loading Port: Vietnam / Scope of work: Full coordination of cargo inclusive unloading

Star Shipping coordinated also successfully projects on behalf of principals at Karachi Port. Cargo details were as follows: Commodity: Long Heavy Gas Capsule / Dimension in m (L/W/H): 25.60 x 4.267 x 3.65 / Weight: 274 metric tons / Delivery: from Karachi Port to site area / Scope of work: Coordination, transportation and surveyance.

Furthermore, Star Shipping completed also the delivery of bulky cargo from Karachi to site in Daharki, Sindh province. Commodity: Air compressors, coolers, engines / Dimension in m (L/W/H): 15.24 x 5.08x 6.35 / Weight 55 tons Loading: Vietnam / Discharging: Karachi

Scope of work: full coordination from Karachi to Daharki site below the details of cargo. The transportation from Karachi to Daharki site took 8 hrs. and 31 min. (584.1 km) via National Highway 5. There were some hurdles we had encountered during the transportation, but managed to transport the cargo safely in accordance with ISO-9001:1500 standards.

Star Shipping finally completed the delivery of 58 tons discharging cargoes from vessel onto a barge (open sea cargo project) operated at Karachi Port. Commodity: Submarine optical fiber cable (double armor) / Dimension in m (L/W/H): 15.3 7.1 x 6.7 / Weight 58 tons / Loading: Shanghai / Discharging: Karachi. This was the first of its kind open sea project handled by Star Shipping and there were no reports of any damages.

Last but not least Star Shipping are proud to announce that the management system of the company has been certified according to the standard ISO 9001:2015. The ISO 9001 covers the development of project cargo warehousing, transportation and logistics.

L.C. van Tiel Logistics handles transshipment to Japan

GPLN member L.C. van Tiel Logistics from Netherlands moved recently a hammer and some other parts into a barge at RHB Stevedoring & Warehousing of the Breakbulk Terminal at Rotterdam Port in Netherlands for direct transshipment. They arranged also the barge transport and charter of the vessel with final destination Japan.

Seashell Logistics recent project shipments

GPLN member Seashell Logistics from India handled machinery from Nhava Sheva Port east of Mumbai to Benghazi in Libya. Volume: 173 CBM / Dimensions in m (L/W/H): 16.40 x 3.25 x 3.25.

Seashell was appointed for handling this shipment basis ex work terms to arrange pick from a factory (which is located at around 1400 km away from port), custom clearance, port handling and freight all had to be planned well. The first challenge was to arrange road transport due to the long length of the cargo, in order to be moved for such long distance, which also involved interstate border crossing. It was done smoothly using 60ft trucks and taking care of RTO clearances at border.

The next step was getting shipper registered at customs. Though they are one of the big established regular exporters, due to recent changes in customs regulation for all shipper’s AD code registration which was a bit time consuming, procedure was also managed smoothly before cargo arrived at port. The next challenge was smooth loading on vessel. However, since this was not a regular breakbulk vessel but a container vessel to accept this unit as BB, the lifting equipment’s and arrangements were different than BB and had to be made available as per cargo’s safe loading requirements. Plus, the lifting points made on cargo were not at same level and not symmetric with COG and also not at center, but little on a foreside of cargo. With expertise of our project team, it was handled skillfully and monitored well. A single piece to this destination would have costed much more on a regular BB vessel which we, with our strong & appropriate pricing skills, could offer to our esteemed client on a container vessel at a very competitive price for this freight.

Furthermore, Seashell Logistics also shipped recently tanks from Mumbai to San Juan Port in Puerto Rico. 3 units, each of them 78 tons and 646 CBM = Total of1938 CBM.

Latest project by Wirtz Shipping

GPLN member Wirtz Shipping & Co NV from Belgium shipped recently two coli’s of 220 tons and some accessories from Antwerp to Taiwan.

We delivered the cargo by barge and loaded it in direct transshipment with lifting equipment on to BB vessel Sophia from dships carrier, handling the cargo with ship’s gear of 2 x 180 tons. The final destination was Port of Mailiao in Taipei and the receiver was a petrochemical company. This port is very small therefore only ships with a max. length of 180 m can enter it.

Furthermore, they shipped also a Liebherr crane by RORO to Sohar in Oman. The crawler main body was 61 tons, plus top section, boom and bottom section and counter weights who had a weight of another 50 tons and two crawler carriers at 25 tons each. They picked up the cargo by truck at Jan de Nul terminal in Oostende and moved it on a Mafi to Antwerp and shipped it with Heroic Leader.

And finally, they arranged another shipment from Antwerp to Taichung in Taiwan for a petrochemical company on RORO vessel MS Hoegh Jacksonville one “loading arm” from SVT in Schwelm, Germany. The weight was 21 tons, plus some spare parts.