A word from GPLN: Newsletter Issue 80 / May-June 2021

This year’s total budget for the global mining industry exploration could be 20% up compared to last year. This is good news for our members who specialize in mining business, but much will depend on the direction of metal prices which is likely to be influenced also by the demand in China and corona situation, as some projects are still on hold. Recent industry figures indicate overall demand for new mining equipment looks positive as the value of the global mining machinery market is projected to grow because new mines are being developed in many places around the world which will increase also the demand for project logistics services.

Further good news for our members in the Balkans region are on the horizon as the region is not only a major market in its own right but an increasingly important shipping location for the global project supply chain. Adriatic ports have developed to the point where they are now important outlets for shipments heading to the Middle East and beyond. Issues, such as inadequate quaysides, cranes and other infrastructure, are starting to be addressed as modernization gathers pace, creating competition for Northern European ports. Chinese money for major projects continues to flow into the region, particularly to Bosnia and Serbia, and there is numerous green energy-, transport infrastructure- and metals mining development. Shipbuilding and repair are also a significant driver of business, besides some LNG developments in Croatia.

The charter rates for multipurpose vessels continue their upward trend and have now broken through the 10,000-dollar barrier. The average charter rate for a 12,500-dwt multipurpose vessel reached 10,285 dollars in June this year. This is in stark contrast to the rate one year ago when they reached their bottom at just 6,381 dollars following the beginning of the corona crisis.

Due to the current situation with the corona virus and considering that the majority of our members are not able to attend our AGM in Bremen this year, we have moved this meeting to 2022 and will announce the new dates and location in due time.

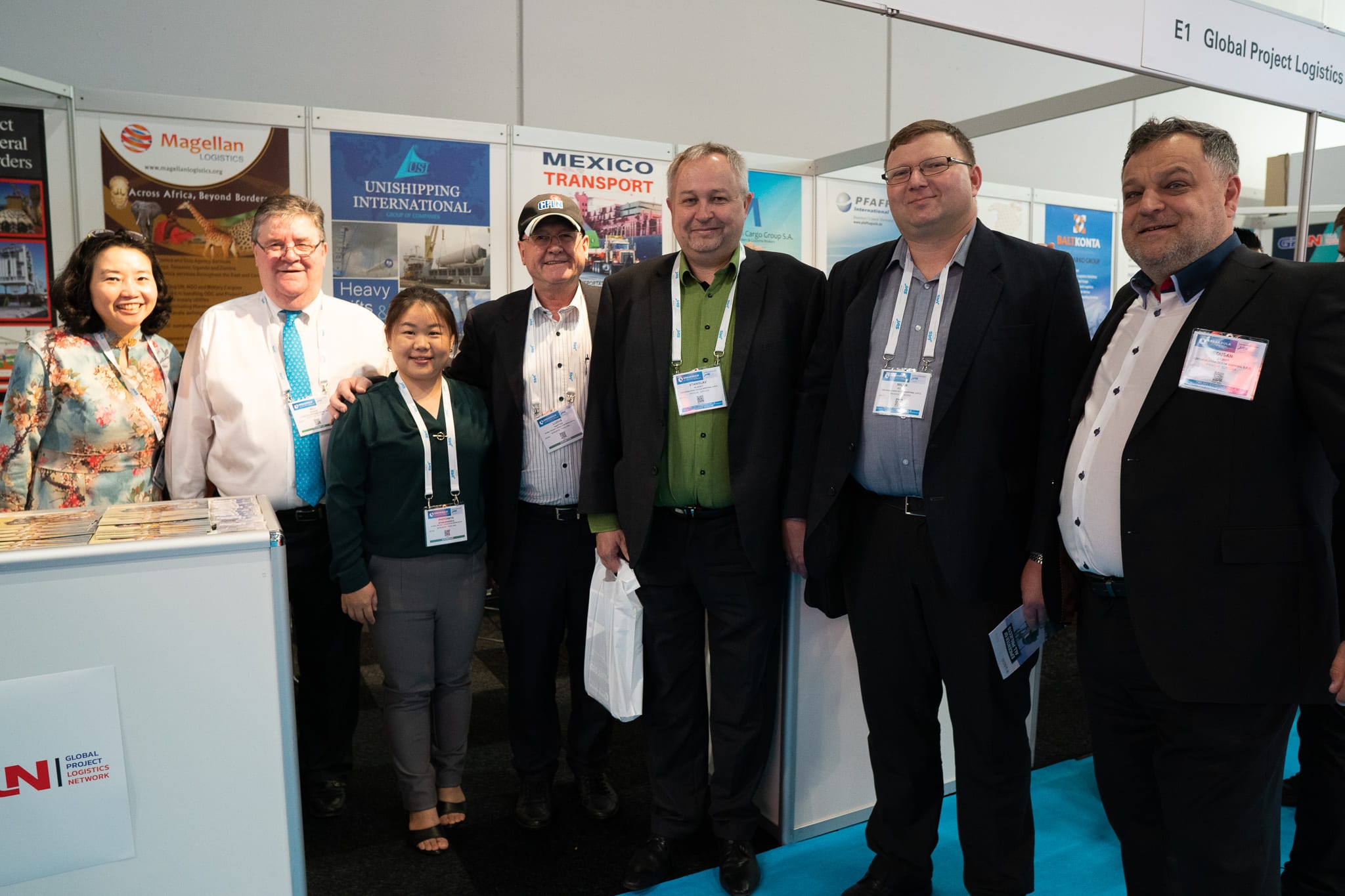

Breakbulk Europe has also been rescheduled to next year and is taking place at Ahoy Convention Centre in Rotterdam from May 17-19, 2022. GPLN will exhibit at this event and has secured a prime location in the main hall. We have tentatively booked 36 sqm which is the equivalent of 4 regular stands. We hope that a lot of members will join us after 2 years away from mingling with fellow project logistics specialists.

All upcoming events are obviously subject that the world is back to normal in 2022.

Stay safe and healthy!

Your GPLN Team

| New GPLN Members / May – June 2021 | ||

| Cyprus | Limassol | Oceanic Logistics Ltd. |

| India | Dahej | Premier Global Logistics Limited |

| India | Hazira | Premier Global Logistics Limited |

| India | Kochi | Navio Shipping Pvt. Ltd. |

| India | Mundra / Kandla | Premier Global Logistics Limited |

| Israel | Haifa | Kamor Logistics Ltd |

| Nepal | Birgunj | Premier Global Logistics Limited |

Greenroad China handles Railway Project

GPLN member Greenroad International Logistics from China has recently coordinated the delivery of 20,000 CBM of cargoes, including six diesel locomotives and other equipment and accessories, for Mexico’s Mayan Train project. This intercity railway will traverse the Yucatán Peninsula on a stretch of 1,525 km. Their transport scope included moving components from Emali in Kenya to the port of Mombasa. The shipment was then delivered to Mexico’s port of Manzanillo and then on to the project’s truck-laying base. The heaviest cargoes weighed up to 138 tons and measured 22m x 3.3m x 4.7m. Greenroad faced a number of challenges, including limited breakbulk vessel capacity, increased freight rates due to limited capacities influenced by the pandemic, and a tight delivery deadline.

After arranging a vessel for the shipment, Greenroad loaded the components directly from the trucks. Besides the ocean transportation, the road haulage was also an important factor. The company carried out a road survey and removed obstacles on a 485 km stretch of road.

SIGMAI delivers Transformers

GPLN member SIGMAI from Israel has completed a successful delivery of 3 transformers, weighing 103 tons and a dimension of 6.20m x 4.35m x 4.30m each, plus 51 cases of accessories, from Turkey to Israel. Due to urgency of this shipment, which was declared as national necessity, SIGMAI was able to coordinate all operational tasks within one week.

From chartering of the vessel, pick up cargoes, local formalities at both ends, sailing, loading & unloading of vessel, up to the delivery to the final receiver in Israel. This was extremely challenging these days due to the heavy congestion and delays at ports, but their team did the impossible-as usual! The loading, stowage and local operations in Israel were all done securely and flawlessly by SIGMAI experts and partners abroad, all leading to a successful delivery and a very satisfied customer.

Best Global Logistics transports modules

GPLN member Best Global Logistics from Netherlands relishes the opportunity to take on significant challenges. The largest of several modules transported from China to Singapore stood approximately 34 meters tall and weighed 900 tons in total. Due to the size and weight of the projects, shipping them was already complicated and, with a chaotic shipping market, COVID-19 outbreaks in local ports, Lunar New Year celebrations in both the origin and destination countries, stringent technical requirements, and an extremely short time window to plan and complete the transport, there were plenty of additional challenges and obstacles to overcome.

Special weight spread and sea fastening solutions were manufactured and developed in record time to the fullest satisfaction of the international MWS requirements. Suitable assets were chartered in the spot market, whereby negotiation of laycan and terms were key to performance and overall cost. Last but not least, technical expertise and engineering capabilities, both in the office and on the job, were critical to completing the project on time, safely, and successfully.

We wish to thank our strong business partners and dedicated colleagues involved in making the job possible.

Total Movements arrange Breakbulk Shipment

GPLN member Total Movements from India takes pride in sharing glimpses of their back-to-back breakbulk shipments from India to Bangladesh. Recently, they shipped more than 52,000 FRT of breakbulk project cargo from Chennai port in India to Mongla port in Bangladesh within just two months’ time amidst the second wave of Covid-19. The consignment included both heavy lifts and small cases. The operation was intensive, hectic, and required advance planning. A major challenge faced while executing these shipments was the announcement of lockdown in both India and Bangladesh, which led to disruption in the port operations. However, their team was persistent to complete the shipment at hand with the support of the port and carrier to meet the client’s requirements.

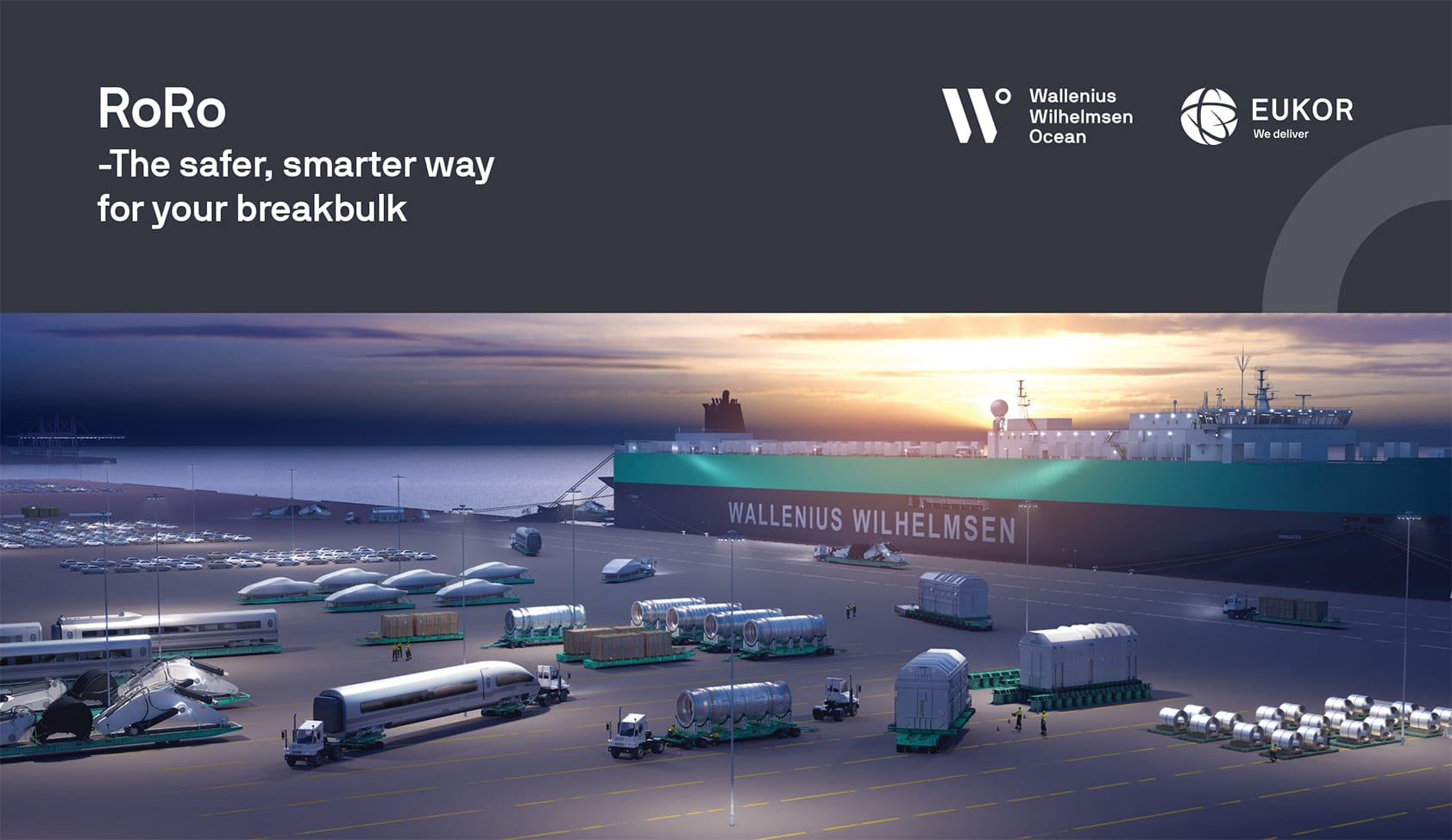

Wallenius Wilhelmsen delivers sustainable RoRo shipment

Shipping the world’s longest press brake from the wilds of Sweden to the US is no small feat. With RoRo’s safe handling and breakbulk capabilities, this record-breaking piece of manufacturing machinery was safely transported across the Atlantic, while cutting greenhouse gas emissions by half. One of the biggest challenges the freight forwarder faced when tasked with shipping a 500-tons Optima press brake from Ursviken Technology’s Skellefteå factory in Sweden to the US was finding a safe and reliable service. Ursviken Technology is based in northern Sweden, where transport options are limited. The manufacturer needed an ocean partner that could transport the shipment from the local port, ensuring faster lead times, lower costs and reduced emissions.

“We knew that loading the cargo in Skellefteå would allow us to cut CO2 emissions by over 50% to Antwerp compared to trucking the big pieces to Gothenburg. Not only that, it would also minimize the risk of damage as the press brake components wouldn’t need to be reloaded,” explained the freight forwarder. Despite Skellefteå not being part of its regular network, Wallenius Wilhelmsen, working in partnership with short sea carrier Wallenius SOL, was able to meet their needs, offering a through bill of lading from Skellefteå port to Charleston in the US.

“Offering a combined transport solution with a Wallenius SOL feeder service connecting to our Atlantic service we were able to deliver a safe, cost-efficient and sustainable solution,” says account manager Anneli Larsson, Wallenius Wilhelmsen, Sweden. Safe handling solutions and technical capabilities minimize risk dismantled into 14 components, some measuring 20 meters in length, up to 4.3 meters in width and weighing over 63 tons each, the press brake required careful handling.

“Drawings and load calculations were made by our technical team in close cooperation with the customer to find the best solution for fitting and loading the pieces on our handling equipment said the freight forwarder.

After careful planning, five 62’ roll trailers and two 40’ roll trailers-part of Wallenius Wilhelmsen’s fleet of equipment for safely handling breakbulk cargo-were used to load the components in Skellefteå with both Ursviken Technology and the freight forwarder present.

“An added benefit of loading at Skellefteå was that both the freight forwarder and the manufacturer were able to inspect the cargo handling, lashing and vessel loading. Loading the product at Skellefteå instead of hauling it long distance by truck also protected the components against rust from the salted roads. Once loaded onboard the Wallenius SOL vessel, the product was shipped to Antwerp where it was discharged and wheeled into storage still lashed to the handling equipment to protect against the elements while waiting for the WW Ocean vessel to take it to its final destination in Charleston, US.

Ms. Anneli Larsson, Account manager, Wallenius Wilhelmsen, Sweden said “Offering a combined transport solution with a Wallenius SOL feeder service connecting to our Atlantic service we were able to deliver a safe, cost-efficient and sustainable solution.” Safe, reliable network supports sustainability efforts shipping direct from Skellefteå not only reduced lead times, it also contributed to a significant reduction in CO2 emissions – a top priority for the freight forwarder and its customer. “We always want to find solutions that are as climate-friendly and safe for our customers’ cargo as possible. The most important factors considering and choosing a partner is a high service level, green mindset and agile thinking.”

By working with partners and expanding a strong and reliable network, Wallenius Wilhelmsen see an opportunity to offer more sustainable transport solutions on their waterways in the future.

Universal Transport Group move Turkish trams to Poland

A total of twelve new trams will be used in the local public transport system in the Polish city of Olsztyn (Allenstein). For the first time, the low-floor vehicles with a track width of 14.35 cm came from a Turkish manufacturer. The project logistics specialist of GPLN member Universal Transport, Group Züst & Bachmeier, was responsible for the transport on the European side. After being picked up from the factory, the tram took the well-known ferry service from the Turkish ferry port Pendik in the province of Istanbul across to the Italian port of Trieste. From here, Züst & Bachmeier took over the oversized cargo.

With four double and two single wing doors on each side, the tram has a capacity of 210 passengers, including 40 seats. From Trieste the transport went through Italy, Austria, and Germany to the final destination in north-east Poland. The special cargo was escorted by police and escort vehicles on its journey. One transport from the port of Trieste to its destination in Poland takes a total of six days. Via the unique heavy Net online system, the customer has access to all current documents and proof of delivery at any time.

In addition, he can track the position of the vehicle in real time. The in-depth preparation of the cross-border transport took a few weeks, this was to ensure as little delays as possible. In addition to planning and registering with all relevant authorities in different countries, it was important to compile the relevant documents such as access authorizations or customs guarantees and obtain the necessary permits. The Züst & Bachmeier team also took care of the coordination with the port agents and customs clearance.

“The Universal Transport Group and its subsidiaries have the necessary expertise in planning, organizing, and implementing international large-scale and heavy-duty transports. We see ourselves as a kind of competence center in which we work out the best solutions for our customers across the group bundled with great commitment, “says Ergin Büyükbayram, who represents the Universal Transport Group in Turkey as regional manager and adds:” Right now customers in the Middle East have a high demand for such well-engineered tools as our heavy-Net. “

Terminal Logistics Services move heavy pieces

Even though considering the complicated situation on the border between China and the Republic of Kazakhstan, GPLN member Terminal Logistics Services’ team (TLS) had a busy spring this year. They have been awarded to move three heavy pieces of Komatsu reclaim feeders from Tianjin, China, to Ridder Mining side in Kazakhstan, for the end user «Kazzinc», a local giant of mining sphere. The scope of work combined everything, starting from the preparations for the customs clearance, certification, as the main challenge was the fact that before this kind of machinery has never been imported to the EAEU region before. Starting from scratch, collecting all needed documents, holding several conference calls between suppliers, end-user and TLS customs department team, brought its benefits, as upon the cargo crossed the border, all operation preparations were finished in just two days.

This was an absolute record for a local customs legislation scope. The shipment included 3 Feeders with a dimension of 12.28m x3.07m x3.27m each, and a total GW of 91 tons, including 11 boxes with spare parts. Two routes and transportation options were planned, as the project was adapted to the current situation with quarantine measures, and longest queues ever at the borders. The first leg was planned via low bed trucks and the second one needed to be loaded on railway platforms. But finally, the whole route was completed on low bed trucks, due to the lack of the railway tare. Anyway, the whole project went very smoothly that the customer even did not noticed changes from plan “A” to plan “B”. The whole route of 4765 km was covered in 32 days, including re-loading at the border and crossing the borders in a queue. We want to take this opportunity to thank our team members and share this success story with all GPLN Newsletter readers accordingly!

Holleman transport heavy equipment and machinery

GPLN member Holleman from Romania recently received a special request for a heavy transport of agricultural equipment and machinery. The most difficult and significant part of the project was represented by the transport of the pieces on the Great Braila Island. Holleman specialists had to find an intelligent solution that would allow the safe transportation of products to their destination. The Great Braila Island is surrounded by water and requires special logistics. Considering the particularities of the transported products, we had to approach the project with special attention.

Parts transported by Holleman and specific features: Grain cylinder dryer with 1900 x 446.2 x 455 m and 46,000 kg / Accessory with 1100 x 350 x 345 n and 30, 000 kg / Complementary piece with 1100 x 290 x 300 m and 4,000 kg. The large part was transported on a trailer, benefiting from steering and hydraulic suspension, for maximum safety. The small parts were transported on normal trailers. The challenge was to cross the water correctly to the Great Braila Island. The ferries were not long enough to accommodate the complete needs of transport, but they allowed us to carry the first two trailers, placed diagonally. The long trailer was transported without the tractor head, which was coupled again on the island. Using a secondary barge and floating cranes, the trailer was partially positioned on the barge, and the two floating cranes transshipped at the same time.

Lysander Shipping handles multiple tasks

GPLN member Lysander Shipping, Denmark, has recently completed the transport of a stainless-steel beam from Korea to Antwerp in Belgium and overnight delivery to Haaksbergen in Netherlands. The structure measured 26.28m x 1.22m x 0.56m, and weighed 5.6 tons, to be used in the construction industry. Due to the length of the cargo, they arranged for a surveyor to check the route from port to final delivery address and an escort to oversee the safe transshipment to consignee.

Lysander Shipping handled also 3 side stream filters, all measuring over 5 meters in height, from FCA Milan in Italy to Stettin in Poland. The cargo was moved by road from Milan area to Porto Marghera and safely loaded on board M/V Nauma to Poland. Lysander had to apply for permits for road transport through 5 different counties in Italy and co-ordinate safe arrival to Porto Marghera, just in time to meet the scheduled part charter vessel.

Höegh Autoliners launching the most environmentally friendly car carrier ever built

Höegh Autoliners is accelerating its decarbonisation efforts to meet its goal of a zero emissions future. Today’s Aurora Class launch is a crucial step in the company’s sustainability commitment. Designed for 9,100 car equivalent units it will also be the world´s largest car carrier.

“With the future of cargos and zero carbon fuels in mind, the Aurora vessels is designed for a greener future. It is the most environmentally friendly car carrier ever built. The Aurora Class represents a big step on our path to a zero emissions future”, says Höegh Autoliners´ Chief Executive Officer Andreas Enger. “We have entered a Memorandum of Understanding with our professional and long-term partner Xiamen Shipbuilding Industry. This will make it possible to have the first vessel delivered by the end of 2023”, the CEO continues.

Höegh Autoliners has a solid history on emission cuts and long-term efforts to combating climate change. We have since 2008 achieved an improved carbon intensity of 37 per cent in our fleet. This has put us in the forefront in sustainable shipping in the deep-sea RoRo segment.

The Aurora class is designed to transport the cargo of the future. Its strengthened decks and enhanced internal ramp systems, enable Electric Vehicles on all decks and provides more flexibility for heavier project cargo. The Aurora Class’ multi-fuel engine can run on various biofuel and conventional fuels, including LNG. With minor modifications it can transition to use future zero carbon fuels, including Green Ammonia.

Hans Eivind Siewers, Segment Director Passenger Ships & RoRo at DNV says, “With the multifuel engine and DNV’s new ammonia ready notation, Höegh Autoliners is bringing the segment and work to decarbonise the maritime industry to a new level. The Aurora design will further meet the enhanced safety standards and reduce environmental footprint significantly. DNV are proud to support Höegh Autoliners on their path to zero. With the right partners, technology, and mindset, we will be able to achieve a safe and sustainable maritime industry.”

Being ready for zero carbon fuels and taking advantage of the latest technology on everything from energy optimization to internal ramp systems the Aurora Class will bring decarbonisation and cargo efficiency to a new level. This will reduce Höegh Autoliners carbon footprint and support decarbonising customers’ supply chain. “We are accelerating our decarbonisation efforts to meet our net zero emissions target by 2040. Together with our customers and trusted partners we will make a significant contribution to a more sustainable maritime industry”, concludes Andreas Enger.

Polaris Shipping Agencies perform various shipments

GPLN member Polaris Shipping Agencies LLC (United Arab Emirates) project’s team was called upon to perform a shipment of approximately 450 MT / 1900 CBM of construction equipments ex suppliers yard in UAE to port Zeebruge, Belguim, for a time bound project. Considering the time taken for refurbishing of machines which included steam washing and painting of some units, Polaris with its close relation with carriers negotiated a deal to have one of their vessels to make an inducement call into Zeebruge after her discharge in Durban, South Africa, enabling to have the shipment connected soonest on completion of required mechanical work and hence meeting the delivery deadline in Europe.

Polaris scope of services included following: Coordinating and liasing for all mechanical repairs / Dismantling of equipments for painting and and fixing back for shipment / Steam cleaning and painting to receivers provided standard / Pre Carriage to port Jebel Ali and all related FOB operations / Ocean Freight up to Zeeburge. This shipment with the heaviest piece of 1 x Caterpillar D9R crawler tractor weighing 50 MT is currently enroute to Zeebruge to the full satisfaction of clients.

Polaris Projects also received their latest break bulk shipment of Seamless Steel Tubing with our scope responsible for local handling of Seamless Steel Tubing strictly as per clients handling procedures at port Hamriyah, Sharjah. Our scope also included receipt from under hook inward vessel to receivers for necessary lining / modifications and further on-carriage to their nominated CIS destination via Poti, Georgia, on completion of lining process. The total volume of around 2100 frt.tons in multiple lots was received stored in our nominated storage yard for inspection by appointed independent surveyors for any damages and further delivered to receivers to their requirement.

Star Shipping handles multiple project movements

GPLN member Star Shipping Pakistan has handled recently a project movement of a Compressor & Cooler with accessories from port Qasim to the Daharki power project site in Pakistan. Specifications: Compressor (LxWxH) 18m x 5.18m x 5.44m and weight of 50 tons. Cooler (LxWxH)14.32m x 2.4384m x 2.7432m and weight of 30 tons Multi-axle & multiple low beds & flatbeds along with a heavy-duty mobile hydraulic crane were utilized to lift this cargo. There were few challenges in transit which were obtaining the road permissions, wildlife and dry weather. Hence the job was done successfully and the cargo delivered in safe and sound conditions. Our operations team and all the other workforce remained also safe and secure.

Star Shipping handled also three transformers weighing 62 tons each, consisting of 3 bulk, solid, fine particles liquid dielectric transformers main bodies. Dimension: 6.64m x 2.77m x 3.33m Loading port was Shanghai, China and discharging port Karachi (SAPT). This contract included different transports scheduled during this year and was successfully completed. Furthermore, Star Shipping successfully completed some other projects for their clients which covered following scope: Loading at Shanghai port in China and discharging cargo from vessel at Karachi port in Pakistan, surveyor of cargo and loading onto trailers, as well as the transportation of cargo for other clients. Commodity: transmission cables & accessories. Scope of Work: shipping & onward transportation. Loading port: Shanghai and discharging port: Karachi.

PROTRANSER delivers cargo safe and timely

GPLN member Protranser’s team from China delivered 2,000 CBM tanks from Zhangjiagang, Jiangsu Province in China to Taichung, Taiwan. The dimension and weight of two largest tanks was as follows: (LxWxH) 32.528m x 4.865m x 4.500m /110tons per unit. Working scope included: pick up cargo at factory, port service at Zhangjiagang port and Breakbulk vessel chartering service from Zhangjiagang to Taichung.

Protranser delivered also a 40-ton boiler from Shandong, north China, to Kyrgyzstan. The set of boilers included the main body and parts which were loaded in a 20′ container. The weight and dimension of the main body was 40 tons and 6.4m x 2.82m x 3.6m. In the field of international road transport services, it is over height and overweight. Our work scope included pick up cargo in Taian city in Shandong province and delivery to Irkeshtam port in Ucha County, Xinjiang, which is a national first-class port. The distance from Shandong to Irkeshtam port is over 4600 km, and it took 5 days.

Our team kept close contact with the client and prepared several backup solutions in order to deal with the sudden change of road- and weather conditions, as well as anti-epidemic policy during transportation. The cargo was reloaded on trucks from Kyrgyzstan at the border and transport ed to Bishkek, the capital of Kyrgyzstan. It will take longer at the border because drivers must take a nucleic acid check and cargo will be disinfected, but the road port transportation situation is expected to ease in the near future.

Furthermore, Protranser’s team was nominated to provide a “one day trip” service for 4 sets of Transverse Thrusters by trucks from the factory in Jiangsu Province, East China, to the shipyard in Fujian Province, South China via BLP (Bonded Logistics Park) in Shanghai. “One day trip” service: cargo is exported to bonded area and imported in one day. The clients can take advantage of the service to save time and cost, comparing with antiquated way by exporting to Hongkong and import back to the mainland.

Finally, Protranser delivered 5 sets of press lines for an automobile factory project from Qingdao, north China, to Richards Bay, South Africa in one lot. The total volume was over 9,000cbm and total pieces were over 500 pcs, 9 pieces of them were over 50 tons and 6 pieces of them were over 100 tons, whereas the max gross weight was 166 tons. Working scope included port service in Qingdao port and Breakbulk vessel chartering service from Qingdao to Richards Bay. Since there were so many heavy lift cargoes and not stackable, we loaded the cargo strictly according to the stowage plan in order to make sure the safety of the cargo. During that time, Qingdao port was congested, but thanks to our good relationship with local port authority, our vessel was allowed to call the berth dire.

Nu-Era Logistics accomplish Industrial Projects

GPLN member Nu-Era Logistics from Canada handled recently special Industrial Projects. They moved OOG heaters for a Natural Gas Station (rigging & transportation) / OOG cable reels as an ocean export job to the UK, as well as transloading & transportation of other oversized items, just to name a few.

AERO AFRICA launches digital airfreight rate platform

Aero Africa, a neutral air cargo solutions group, has recently launched its digital airfreight rate platform to cater to the needs of the African freight & logistics community. The new airfreight gateway and consolidation portal will be available exclusively to freight forwarders & transport-related companies, providing instant air freight wholesale rates, consolidation schedules, and digital bookings from major global hubs to 84 airports in Africa starting in Southern Africa by June 2021. The new platform is powered by Hashmove, a leading digital transformation provider based in the U.A.E. “Combining our extensive experience and expertise in air freight, with Hashmove’s technological capabilities, will open up new and innovative ways for African logistics providers to conduct airfreight business, which will transform traditional notions of efficiency and routes to market. “This is the first of many initiatives we are planning to release this year, which will bring enhanced value to the African logistics community as a whole. Aero Africa operates neutral scheduled air freight consolidations services from Asia and Europe to selected gateways in Africa. The portal will enable us to digitize effectively the air cargo logistics B2B community and to provide full visibility and transparency to our client’s airfreight import business. “The platform has been built tailored to the needs of the African logistics market, taken into consideration every small detail of the air freight procurement and consolidation management model at each gateway and African destination,” said Jade Da Costa, CCO of Aero Africa.

Super Cargo Transport delivers acrylic panel

GPLN member Super Cargo Transport from Vietnam is glad to announce that a big acrylic panel was safely delivered from discharging port to jobsite in May 2021. They came up with a solution for direct receipt under hook at berth, temporary storage at storage yard and safe delivery to the jobsite. Dimension and weight: (L)18,85m x (W)6,85m x (H) 2,49m and 65.5 tons.

Mohab handles Terex crane

GPLN member Mohab from Tunisia handled recently a Terex crane for their oil & gas customer based in Hassi Messaoud (South of Algeria).

Services that were performed are as follows: Reception of the crane at Tunis port / arrangement of all in transit customs formalities as final destination of the crane was Algeria / crane moved into bonded warehouse in Rades, Tunisia / Load the crane into special lowboy once export customs formalities were ready / preparation of the convoy and escort to the Tunisian / Algerian border / handling both unloading and reloading procedure at the border to avoid Covid quarantine procedure for the drivers. They have also arranged all necessary permits of circulation due to height exceeding 4 meters and have prepared a method statement and route to be taken for the job. Congratulations to the Mohab team for their commitment and job well done!