A Word From GPLN: Newsletters Issue 85 / March-April 2022

Dear Reader,

First of all, good news for travellers to Rotterdam! People travelling to the Netherlands from within the EU/Schengen, the obligation to have a test, recovery or vaccination certificate has ended on March 23, 2022. Travellers from other countries can also enter the Netherlands if they have a valid proof of vaccination or proof of recovery. Furthermore, the Netherlands has dropped its remaining domestic COVID-19 restrictions since March 23, 2022.

GPLN is happy to announce that by end of April over 140 GPLN delegates have already registered for the Annual General Meeting which will take place at the Hilton Hotel in Rotterdam from May 20-22, 2022. Our technical course which is taking place on May 20 right after the Breakbulk event is also going ahead with over 20 attendees.

Considering the ongoing Covid situation this is a great outcome and proves once more that our projects network has the highest annual conference attendance in this industry which is thanks to the professionality and commitment of our GPLN members all over the globe.

The tragic war in the Ukraine has badly affected the Antonov Airport in Hostomel near Kyiv and the world’s largest aircraft, An-225 Mriya, has been destroyed during a Russian attack. This is a huge loss to the aviation and heavy lift industry. Besides potential damage to the aircraft on the ground, future maintenance of Antonov’s fleet could be in jeopardy as its main facility for this work is located in Kyiv. Airfreight is feeling immediate effects of the conflict. Airspace closures are disrupting connections between Asia and Europe.

On the shipping side, lines have withdrawn from Russia such as Maersk, MSC, CMA CGM, and ONE among the carriers suspending bookings to and from the country to varying degrees.

China’s zero-covid strategy has seen major cities lockdown in response to a surge in cases. Shanghai and Xi’an have implemented lockdown measures, while the port city of Shenzhen started also a full lockdown. Last year, a covid outbreak at Shenzhen’s Yantian port sent shockwaves through the supply chain. This time round, ports and terminals are said to be operating normally but with land-side logistics impacted there are bound to be implications for global trade.

The situation will worsen delays and create bottlenecks, adding further pressure to an already tense supply chain. Hopes that this year would see a stabilisation of rates, an opportunity for forward planning, or even a return to something close to normal are quickly dissipating. As it stands now, 2022 has shaped up to be another difficult year for the supply chain.

As announced earlier, the GPLN team is exhibiting together with 12 GPLN member companies at Breakbulk Europe at a spacious GPLN booth in Hall 1 and we are looking forward to welcome visitors at our stand #1A20 from May 17-19, 2022 at Rotterdam Ahoy convention centre in Rotterdam.

Safe travel and stay healthy!

Best regards,

Your GPLN team

Universal Transport supplies steel beams

No task is too big or too complex for GPLN member Universal Transport from Germany. This shows with our transport of steel beams for a railway bridge in Lübeck, as the expectations for the traffic diversion measures on the route from Slupca in Poland via the port of Lübeck to the construction site on the Trave are high. Traffic signs had to be dismantled along the route, roundabouts secured with wedges for crossing and green areas had to be laid out with slabs. For example, when preparing for a particularly difficult maneuver on a section in Poland near Wezel/Iwno: The specialists from Universal Transport drove over specially secured lawn onto the S5 motorway, which they then had to reverse through.

For this, traffic even had to be stopped on a connecting road. Preparation and planning of these transports were a giant task and took about a year. Even with all this planning and preparation, the route had to be changed at short notice at the beginning of the transport. An extension of roadworks at the Frankfurt/Oder border crossing saw us taking a detour via Gorlitz. This was the reason why the first transports in March took three nights instead of the planned two. For the first construction phase, eight transports were on their way to Lübeck in March and April, another eight are expected to follow for the second construction phase in September and October 2022. The steel beams were loaded and secured on semi-trailers. The truck with the load had a total weight between 77 and 95 tons. On arrival in Lübeck, the steel beams were then installed during rail traffic closures overnight.

They were placed on the bridge structure by crane and edged with concrete. In the end, the effort was worth it so that the replacement of the bridge at the train station in Lübeck could be completed on time. The construction of the new four-lane road over the local railway line will take place in two construction phases. The opening for traffic is planned for autumn 2024. The total cost of around 36.4 million Euros is financed by Deutsche Bahn and the Hanseatic City of Lübeck.

Universal Transport moves heavy generators

GPLN member duo handles shipment

GPLN member Lysander Shipping from Italy handled recently a local delivery for fellow GPLN member Pfaff International from Germany. They arranged the OF from Antwerp to Cagliari via Salerno and we took care of the local delivery from Cagliari port in Sardinia to the final site. The vessel arrived just in time for us to organize delivery before New Year’s Eve.

We organized collection from Cagliari port and delivered successfully to the final site on 27/12. But we had to carry out the transport at night to the comply with local road restrictions and had to postpone the permits, due to a slight delay of the vessel into Cagliari.

|

New GPLN Members / March – April 2022 |

||

| Australia | Melbourne |

AAW Project Logistics |

| Colombia | Mosquera | DAP Cargo Line SAS |

| Germany | Numberg |

CJ ICM Logistics GmbH |

| India | New Delhi |

Prologis Freight India Pvt. Ltd. |

SCACLI completes airport construction project

GPLN member SCACLI from Canada recently completed another airport construction project – the L.F Wade International Airport Redevelopment Project (the “L.F Wade Project”). The award winning $267 million job began in March 2017 and was a multiyear project. The L.F Wade Project included the construction of the new 288,000 sq. ft terminal, construction of additional apron space, light systems installations for the apron, modifying the taxiway, installing new aircraft hydrant refueling systems, and de-commissioning a majority of the current terminal.

SCACLI, an industry leader in International Projects Freight Forwarding, was nominated to manage and oversee all the transportation requirements.

Maria Misurka, COO and Partner explains, “Moving cargo to Bermuda had its unique challenges and as the Project Manager, the Bermuda team and I found solutions with our many partnerships and contacts around the world. SCACLI’s role consisted of project management, marshalling, and cargo movements from origins such as USA, Canada, UK, Spain, China, and the Netherlands.

Large scale construction jobs such as the L.F Wade Project require expertise and customized planning. SCACLI worked closely with all parties by organizing chartered vessels, barge movements, and mobilization of heavy equipment. Additionally, SCACLI arranged ocean container shipping, consolidations, air cargo expedite, and air charter shipping on behalf of our customer and their subcontractors. This work was completed not only for the new terminal, but also for the runway, hangars, offices, boarding bridges, aircraft refueling systems, HVAC, and security systems.

SCACLI customized plans and managed every PO from the moment it was issued until the cargo arrived customs-cleared delivered to site, while shipping everything required to build this airport, from small tools, parts and dangerous goods to heavy construction machinery, vehicles, cranes, the asphalt plant, backhoes, bulldozers and graders.

Misurka states “SCACLI is proud to have been trusted to manage the shipping for the construction of this multi award winning airport L.F Wade Project which is now open and has transformed the airport experience for visitors to this “Bermudaful” island.

Polaris Projects handles several project shipments

GPLN member Polaris Shipping Agencies LLC (United Arab Emirates) project team was busy executing several project shipments recently. Following shipments were handled successfully:

First of all, Polaris Projects was responsible for receiving of 1 x rotor with shipping dimensions of 14.328 x 4.500 x 3.880 meters (LxWxH) and100 MT which was received from under hook heavy lift vessel at Port Khalifa,

Abu Dhabi retained on stools/beam support to complete necessary formalities by receivers and subsequently safely delivered to consignee once their processes was completed and factory ready for receiving the heavy lift. Being shipment for one of our prime accounts, Polaris’s scope covered receipt from Under Hook inward vessel, necessary third-party independent route as well as cargo survey, shifting from discharge berth to temporary storage, final customs clearance and road delivery to Receivers which was carried out to the full satisfaction of Receivers.

Additionally, above Rotor was shipped on Mv BBC Sapphire and Polaris being agents of BBC Chartering in all Middle East Ports it gives an additional advantage for the Receivers to co-ordinate with our team who controls the complete operation avoiding any misunderstanding / operational delay as the entire local operation is being handled by our Agency & Project Departments hand in hand.

Furthermore, Polaris Projects handled also several shipments of construction equipment’s has been awarded another repeated order for time bound delivery of offshore pedestal cranes ex Port Klang, Malaysia to Abu Dhabi. Both shipments combined with around 140 MT / 1150 freight tons were awarded to Polaris by our overseas associates with strict delivery deadline which was executed on time as agreed. Polaris’s scope included receiving from alongside vessel, complete all related Customs requirements, third party independent surveys, close coordination with Receivers and smooth delivery as per receiver’s requirement and satisfaction.

Global Shipping Service handle urgent shipment

GPLN member Global Shipping Services from USA recently completed a very intense, time sensitive shipment from Louisiana to Singaporefor their number 1 client, Oil & Gas / Renewable Energy customer.

We started the process in October, looking at ways to meet up with their offshore vessel. Initially it would be Guam, which is tricky as it’s a US Island territory in Micronesia Pacific Ocean, which meant Jones Act vessels.Then they switched to maybe meet the vessel off Hawaii, so we had to review again and find options to Hawaii, again Jones Act is a factor. Then they discussed Singapore! but we persevered and worked up options from Houston and WC Los Angeles to Singapore.

Finally, it came down to timing, when would the cargo be ready, where could we meet the vessel in time for the vessel to come into port, collect the equipment and mobilize offshore to the project location. The answer finally arrived end of February and it was decided to go to Singapore. However, we needed the fastest transit time possible, which still meant routing all the way to the West Coast, Los Angeles for a 24-day transit time, direct sailing with CAM-CGM as Breakbulk.

The cargo itself consisted of 2 breakbulk pieces, 145,000lbs and 125,000lbs plus 21 miscellaneous OOG pieces, which we would load to 7 x 40’ OOG flat racks. Timing was the problem. The cargo was not ready until the very last minute and we had to truck it 1,894 miles or 3,048 kilometers. Arriving late and missing the vessel was not an option.

We chose a number 1 Californian trucker, with a stellar reputation and great equipment. Not the cheapest but the best for sure. Your members may not all be aware but California has the strictest road permitting rules for OOG & Over weight and truckers in general, so we needed a Californian trucker to handle these loads. Jamie Lee nominated Piazza trucking, Mike Piazza was our main contact and the communication was seamless. The loading day arrived, I was on site at the loading point in Louisiana to coordinate truckers, crane and the customer yard personnel.

After 3 long days on site, sore feet and calf’s, we were done. Now we moved to the next phase, getting them across the country to Los Angeles and getting the flat racks loaded and secured to meet the vessel cut off.

The Breakbulk pieces were direct delivery to the vessel Tackle – Tackle, and we could only enter the Port of Los Angeles 1 hour prior to our loading appointment at noon on Friday.

Inter American Cargo Group move Galvanized Steel Coils

GPLN member Inter American Cargo Group S.A. from Argentina would like to share their latest project: movement of 650 pre-painted galvanized steel coils with a total weight of 3.570 tons.

The origin was Zhenjiang port in China and the final destination Campana port in Buenes Aires, Argentina.The logistic involved for all stages was as follows: chartering, parcel service, port coordination, custom clearance, transport and final placement within the Buenos Aires limits.

For this particular project Inter American Cargo Group accomplished the requirements of one of the most import construction companies in Argentina, providing essential material for their activities.

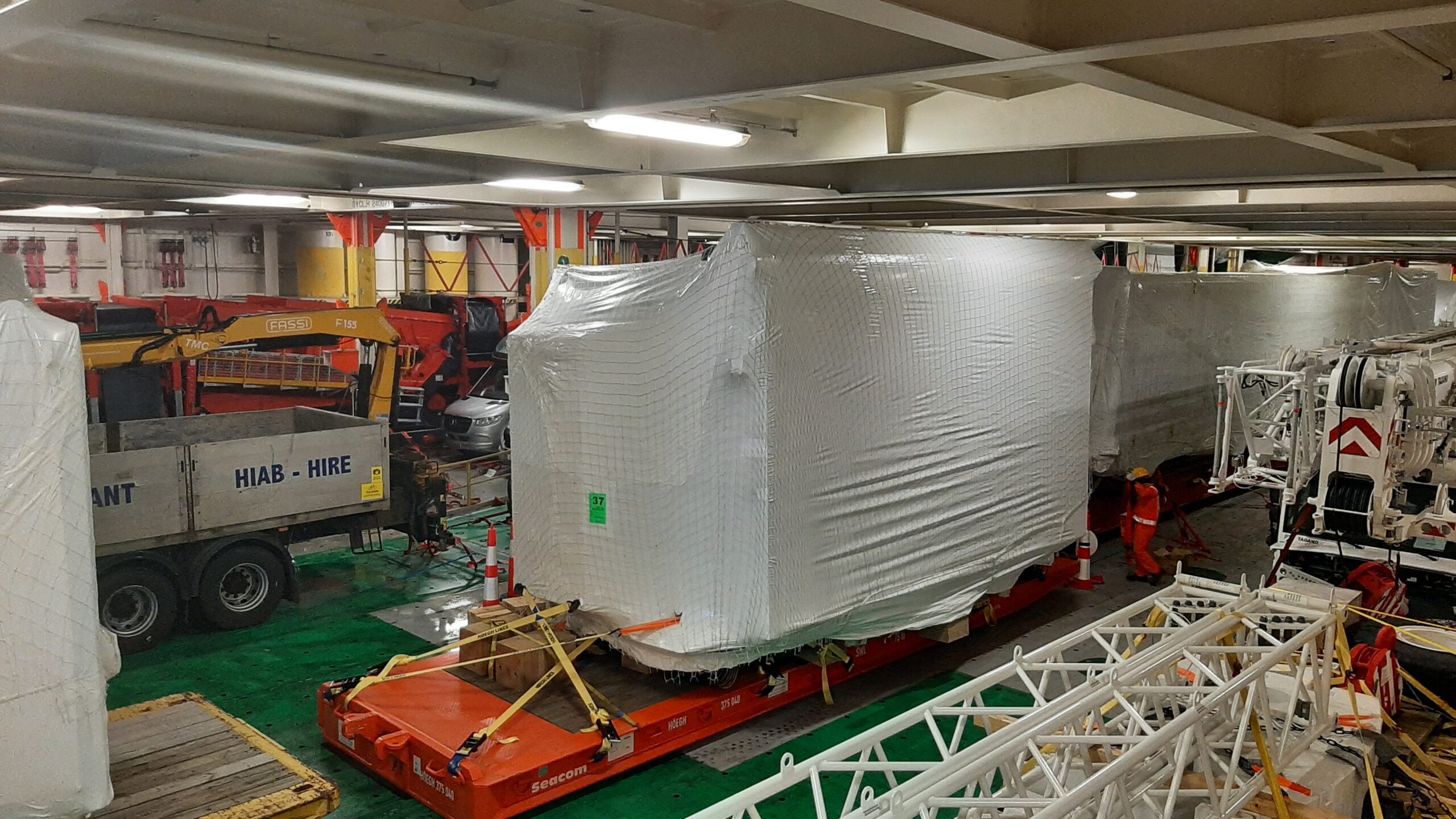

Multitraden Spain delivers steel structure units

GPLN member Multitrade from Spain has recently delivered in Liverpool a lot of 950 CBM OOG units that were part of a disassembled steel structure.

Biggest unit had a length of 27 m and a weight of 17 tons. Maybe not challenging itself, but, using our owned roll trailers, we provided an optimal solution for the customer, avoiding uncertainty of chartered ships or road regulations, and using carriers with high frequency sailings and flexibility in size for each shipment.

We have all usual resources available for transportation of project cargo from A to Z, regardless of what is the best option: heavy haulage, full or part charter, barge, ro-ro or container ships, and of course our roll trailers.

During last 35 years Multitrade Spain has gained huge experience in developing all range of industrial projects. With our owned roll trailers, between 62 and 111 feet in size, we can either handle rolling stock cargo or OOG static cargo, taking advantage of the ro-ro and short sea shipping network around Europe. When you rely on experienced trained team, at the end it is a matter to dedicate time and develop customized solutions together with our customers and agents

And finally flanges by 40’FR from Shanghai, China to Bilbao, Spain, 4 to 8 40’FR per week, since January 2022. The dimension and weight of each package cover was from 3.18 * 3.18 * 1.19m / 9,540 kgs, 3.434 * 3.434 * 1.8m / 11,076 kgs to 3.621 * 3.621 * 1.52m / 11,764 kgs. The total weight of cargo per 40’FR was 34,780 kgs. Working scope included arranging workers to lash cargo on flat racks in the factory, picking up cargo and delivering to Shanghai port and shipping to Bilbao by container vessel.

Megalift handling transportation for new Power Plant

GPLN member Megalift from Malaysia are happy to announce that they have started handling the import for the construction of 1,200 MW Gas-fired, combined-cycle Pulau Indah Power Plant in Port Klang. Cargo: Heat Recovery Steam Generators (HRSG). Dimension: L 31.93m x W 4.53m x H 4.195m. Weight: 165 tons each. The first shipments involved sets of Heat Recovery Steam Generators (HRSGs) shipped via both containerised and breakbulk vessels.

Megalift was appointed as the official project logistics service provider in Malaysia, and we will be taking charge of all transportations until all the shipments are delivered. The project is expected to see its completion in the year 2024.

A Transformative year for Höegh Autoliners

2021 was a very eventful year for Höegh Autoliners. It was a year of successful changes, milestones and a remarkable strategic repositioning. All which have laid the foundation for a very bright future.

In 2021, we reached significant milestones in our continued strategic development. We launched our zero-carbon ready Aurora class vessel design and green fleet renewal program. Additionally, we completed the sale of our logistics assets, refinanced our existing debts, and were admitted to trading on Euronext Growth Oslo. The funds raised enabled us to finance the first four Aurora Class vessels and enter into a contract with China Merchants Heavy Industry to build up to 12 of these vessels, says CEO of Höegh Autoliners, Andreas Enger, and adds that he has never been witness to such a marked strategic repositioning in a single year.

Deep sea PCTC shipping is a highly competitive business, and the last decade has been challenging for the entire industry. Oversupply led to declining rates and reduced profitability.

They delivered also 1 set of transformers from Wuhan, China, to Cartagena, Colombia. The weight of the main body was 28.6 tons. The total volume was 22 packages / 5,1740 kg / 128.7 CBM. Working scope included picking up cargo from the factory by low-bed trailers to nominated warehouse in Shanghai. The cargo was shipped by container vessel. Protranser delivered another 2 sets of transformers from Wuhan, China, to Karachi, Pakistan, in two lots. The weight and dimension of the main body was 55.3 tons and 6,040*2,580*3,430m. The total volume was 36 packages /14,8410 kg / 271CBM. Working scope included picking up cargo from the factory by low-bed trailers to Shanghai Zhanghuabang port and port service. Protranser handled also other project cargo, as follows: Tanks from Shanghai to Kaohsiung, Taiwan, by chartering a breakbulk vessel. The dimension and weight of the largest one was 16,770*4,100*4,000m and 4,3202 kg. The total volume of the lot was 165 CBM / 176.72 tons.

19 mining trucks from Shanghai port to jobsite in DRC via Durban port, South Africa. The weight of each truck was 30 tons, and total volume was nearly 2600 CBM. Working scope was from collecting cargo at Shanghai port, chartering breakbulk vessel from Shanghai to Durban and delivering trucks to DRC by low-bed trailers. And they delivered another 20 mine trucks, plus 3 excavators from Shanghai port to jobsite in DRC via Durban port, South Africa. The weight and dimension of each mine truck was 30 tons and 9,350*4,100*4,400 m, and total volume nearly 4000 CBM.

Working scope was from collecting cargo at Shanghai port, chartering breakbulk vessel from Shanghai to Durban and delivering trucks to DRC by low-bed trailers. 28 bundles seamless steel tubes from Shanghai to Vietnam by sea, all cargo was stuffed in one 40’GP. The length of tubes was from 5m to 8m. Total volume was 28 bundles / 25,690 kgs / 15.5 CBM.

This year will be the year where we prove the efficacy of our business model. We have just exited a prolonged period of depressed earnings. 2021 was the year we reset our ambition and attained the financial capacity to invest in a greener fleet of the future, says Lise Duetoft, Chief Strategy and Analytics Officer in Höegh Autoliners. Höegh Autoliners has indeed seen an increase in its market value during 2021. As Duetoft cautions, the industry is sensitive to wider swings in the economy, but there are reasons for optimism going forward.

We doubled our profitability from the second to fourth quarter in 2021. This is due to increased rates during the pandemic and a lack of capacity in the industry. At the same time, we are positioning the company towards a net zero emissions future, Enger states. The new Aurora class vessels is key to positioning Höegh Autoliners as a front runner in sustainable shipping.

Our goal is to provide zero emissions deep sea transportation as soon as zero carbon fuels such as ammonia is widely available and a viable fuel for shipping. Furthermore, we aim to be carbon neutral by 2040 – 10 years before the goal set by the International Maritime Organization.

Balkonta delivers wooden modular housses

GPLN member Baltkonta from Lithuania has recently completed a door to door delivery of 36 wooden modular houses from Lithuania to Sweden. The dimension of each modular house was 6 meters in length, 4 meters in width, 4 meters in height and with a weight of 16 tons each. The team of Baltkonta was responsible to arrange delivery of modular houses from a factory in Lithuania to Klaipeda port (distance 300 km). Other responsibilities were to make a route survey, issue special permits and arrange private escort for all abnormal transport units, when driving in Lithuania.

Thereafter, all modular houses were loaded and secured safely on a coaster vessel, which was chartered for the next phase of cargo delivery from Klaipeda port, Lithuania to Stockholm, Sweden. The final stage of this multimodal transportation was to reload the cargo onto the road transport again in Stockholm, Sweden, and to deliver it to the job site at a distance of 100 km. The main challenge there was a very tight delivery schedule. Thanks to the professional team of Baltkonta company. The project was done successfully and on time.

Turk Logistics handles several challenging tasks

GPLN member Turk Logistics from Bahrain performed a multimodal transportation of 14 units of a Steam Turbine Generator and Generator Step-up transformer for a Water and Power Plant in Bahrain. As part of this project, Turk Heavy Transport successfully delivered several of these units with a weight range from 207 MT to 343 MT per piece. During the arrival of the shipment in Bahrain, the Turk team received the shipment from the ship hook and placed it on the stools support to complete the customs formalities.

On a later date it was rolled directly from the port to the barge and the same method was performed during discharge at the private jetty. From the private jetty to the project site cargo was transported by road. A Self-Propelled Modular Transporter was used. With the critical overweight in mind, this movement was meticulously planned. Our technical & project operations team communicated with the client in advance about the civil works required at their premises to ensure a smooth operation.

A detailed route survey was conducted, during which our technical team considered various metrics, including turning radius, several calculations to ensure safe transportation, and local permits were also obtained in advance to ensure timely delivery of the cargo.

Finally Turk Logistics moved an overlength Vertical Telescopic Suction Pipe from Bahrain to Durban, South Africa. The dimension was 22,00 x 2,05 x 2,40 meters and the weight 10 tons. The shipment schedule was a particular challenge due to the lack of a Mafi trailers and limited Ro-Ro service from Bahrain. The Mafi trailer was repositioned from Singapore, arrived in Bahrain at the same vessel where the export cargo was loaded. As soon as the Mafi trailer was discharged from the vessel Turk was given 3 hours to complete all the formalities that included the stuffing & lashing on the Mafi, marine survey, as well as customs inspection. The timeline was met, and the cargo arrived in Durban port on time

Civil works were also carried out enroute from the private jetty to the project site. There were two barging operations to complete the deliveries. Turk Logistics also successfully delivered a total of 48 Pressure Vessels. Internal shifting within the client premises, road transportation from the client site to the nearest jetty and Roll into Barge were all part of the scope. Each Pressure Vessel had a weight of 91 MT and a dimension of L 22.00 x W 5.50 x H 6.64 meters each. The Turk project team made detailed and thorough planning to organize this movement, allowing for a smooth execution of the delivery.

Consolcargo moves electric transformer

Commemorating 20 years’ experience and performance, GPLN member Consolcargo SAS from Colombia has been increasing its project cargo management presence on the Colombian logistic market. Recently they have moved an electric transformer 45 MVA – 139/13.8/7.3 Kv. and around 137.584 m3 / 53 tons from Dos Quebradas Risaralda to Saint John, NB Canada. The scope for the project covered the whole movement from factory to Canada, including customs procedures for the exporter and arranging cargo lashing on the lowboy truck in the factory, picking up cargo and delivering to port for transshipment into flat rack 40´ with its corresponding lashing certification. Consolcargo SAS is providing tailor-made solutions designed to move project cargo for companies involved in transportation, petrochemical, power generation, constructions and among other heavy industries.

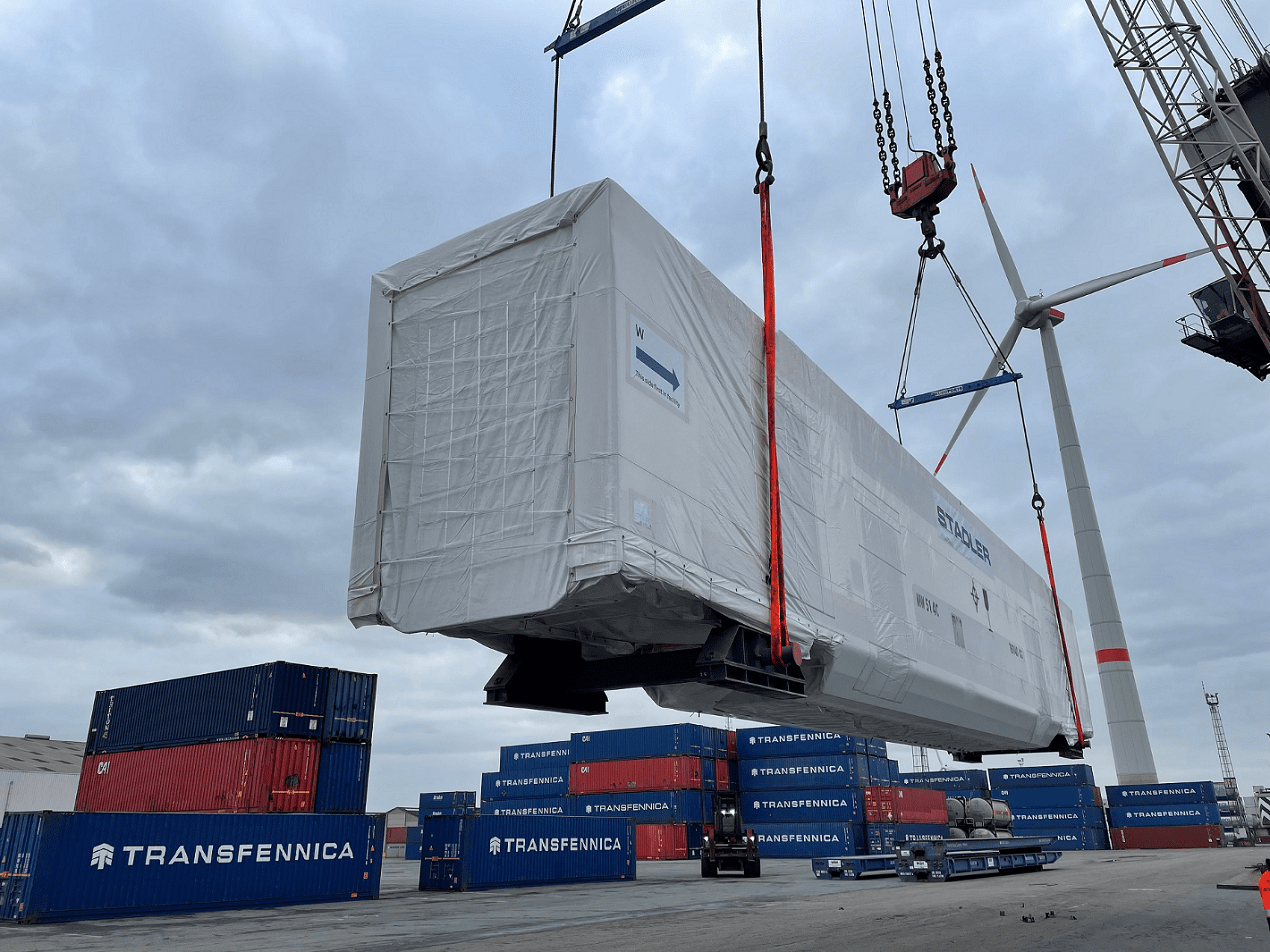

Wallenius Wilhelmsen RoRo delivery for electric train project

Tasked with the transportation of high-value Stadler rail car shells, a freight forwarding and project logistics expert required a shipping partner with a good sailing frequency to meet its project timelines and a high level of technical expertise to ensure zero-damage delivery.

Destined for a new commuter line in California, a total of 133 rail car shells are and will be produced in the following months at Stadler’s manufacturing site in St. Margrethen, Switzerland. To meet project deadlines, multiple shipments are required to support a steady flow of produced units from the manufacturing site to the final destination in North America.

With its RoRo liner schedule, WW Ocean was able to support the customer’s need for regular product flows, while our expansive handling equipment fleet, arguably the biggest in the RoRo market, not only helped to minimize the risk of damage when shipping high-value rail products, but also drives efficiency.

This cargo was really fragile and it had arrive in damage-free condition,” said Joris Verhaag, sales manager for breakbulk, Germany, adding that one of the advantages of our RoRo vessels is that we can stow the units on roll trailers ahead of vessel arrival at the port of loading, which not only allows for more time to safely load the products onto roll trailers, but also results in more efficient terminal operations.

A large equipment fleet also means greater access to specialized equipment, in this case extra-length 72ft and 80ft roll trailers with imbedded rails specially designed for rail cargo. These rails allowed us to roll rail cars over to the roll trailer from a low bed truck if needed to further ensure safe loading, although this isn’t required for these rail car shells as they have no boogies, says Verhaag.

Tasked by Stadler to manage the entire multi-modal transport chain from their manufacturing site in Switzerland to the river port in Basel where the rail cars were then transported by barge via inland waterways to Antwerp Euroports and loaded onto RoRo vessels for the ocean voyage to Galveston. To ensure the success of each shipment, the customer relied on comprehensive preparation.

Our team of technical engineers was on hand from the beginning to draw up the necessary calculations, method statements and drawings in order to ensure safe handling of the products,” explains Verhaag. The customer cargo coordination team, who were tasked with finding the right vessel to accommodate products of this size, is equally important in the planning and success of these shipments.

PROTRANSER handles various shipments

Protranser’s team delivered recently 4 sets of transformers from Wuhan, China to the Philippines. The gross weight of the main bodies was 77.3 tons and 118 tons respectively. The total volume was 122PKGS / 479403KGS / 791.7 CBM. Working scope included: picking up cargo at the factory in Wuhan, Central China, and delivery to the Shanghai port by trucks. They delivered also another set of transformers from Wuhan, China to Australia. The gross weight of the main body was 68.2 tons and the total volume 21PKGS / 85858KGS / 184.5CBM. Working scope included: picking up cargo at factory in Wuhan, Central China, delivering to Taicang port by trucks, which is nearly 800 km away and port service.

In another shipment Protranser delivered 12 Automatic Dump Trucks from Durban port to DRC. The trucks were transported by the way of dismantling into various parts. The total volume was 240PKGS / 6228CBM / 1212 tons. This is the largest mining truck on the DRC market now. Working scope included collecting cargo at Durban port and delivering to the jobsite in DRC by trucks.

And they handled Hydro equipment from Qingdao, North China, to Vancouver, Canada. The cargo were parts of turbine spherical valves. The total volume was 29 PCS / 64053KGS / 133.45CBM. Our working scope included picking up cargo from the factory in Tianjin, delivering it to Qingdao port and shipping it to Vancouver by Breakbulk vessel.

With the Covid 4th wave, the Omicron variant hit and outbroke in China in March this year, and it became very difficult to find trucks to pick up cargo because no one wanted to take risk to be quarantined for 14 days, which could happen suddenly if someone would be diagnosed positive in the area. But our team didn’t give up and kept to check in the market and achieved it after 3 days and helped our client to catch the vessel on time.

Transit transport in the Republic of Kazakhstan

The Republic of Kazakhstan is located in the center of the Eurasian continent between the largest economically developed countries of Europe and Asia. Terminal Logistics Services uses this geographical feature and supports international transport flows, including the transit potential of the Republic of Kazakhstan. The perspective directions of transit are the following: to the EU countries; to China, Japan, South-East Asia countries; through Central Asia and Transcaucasia to Iran and Turkey. For each of these directions, there are transport corridors by land and waterways.

Two transport hubs are important for transit in the Republic of Kazakhstan: Dostyk-Alashankou railroad in the east of the country and the sea port of Aktau in the west. The Trans-Caspian international transport route (Middle Corridor) is

successfully used and by the end of 2022 Kazakh exporters will redirect up to 4 million tons of cargo to European countries. The Kazakhstan Company Terminal Logistics Services is a leader in project logistics and has 30 years of successful experience in both freight forwarding and customs clearance. We are open to cooperation and are ready to individually offer logistics solutions for each customer, including transit. Qualified specialists and an optimal management structure allow us to approach any logistics tasks with maximum flexibility and speed. The Terminal Logistics Services team has an impeccable reputation and has won numerous national and international awards.

Total Movements handle WTG components

GPLN member Total Movement successfully moved WTG components from the supplier’s factory to the load port on India’s east coast for one of their valued partners.

For a prestigious project in Europe, we moved a total of 5 units of WTG, including 15 x 44 m long blades, a 5 x 50 MT generator, hubs, and accessories. We were able to accomplish this because we had exclusive access to a specialized fleet of vehicles at our disposal, as well as closely integrated teamwork, as we had to traverse the heart of the city to reach the port amid numerous construction activities for the city’s metro project. The authorities outrightly denied permission for the movement of such oversized cargo. However, our team organized a joint meeting with the Metro, City Corporation, Police, and Port Authorities to ensure that all necessary precautions were taken during the movement to ensure that no construction activities or infrastructure changes were disrupted. Aside from that, technical documents were submitted to their satisfaction in order to obtain permission. The entire cargo was docked in port well ahead of the vessel’s arrival and loaded onboard for a Happy Sailing. This movement brought us immense pleasure because it allowed us to contribute to renewable energy, which is nothing less than an investment in our future.