A word from GPLN: Newsletter Issue 91 / March-April 2023

Dear Reader,

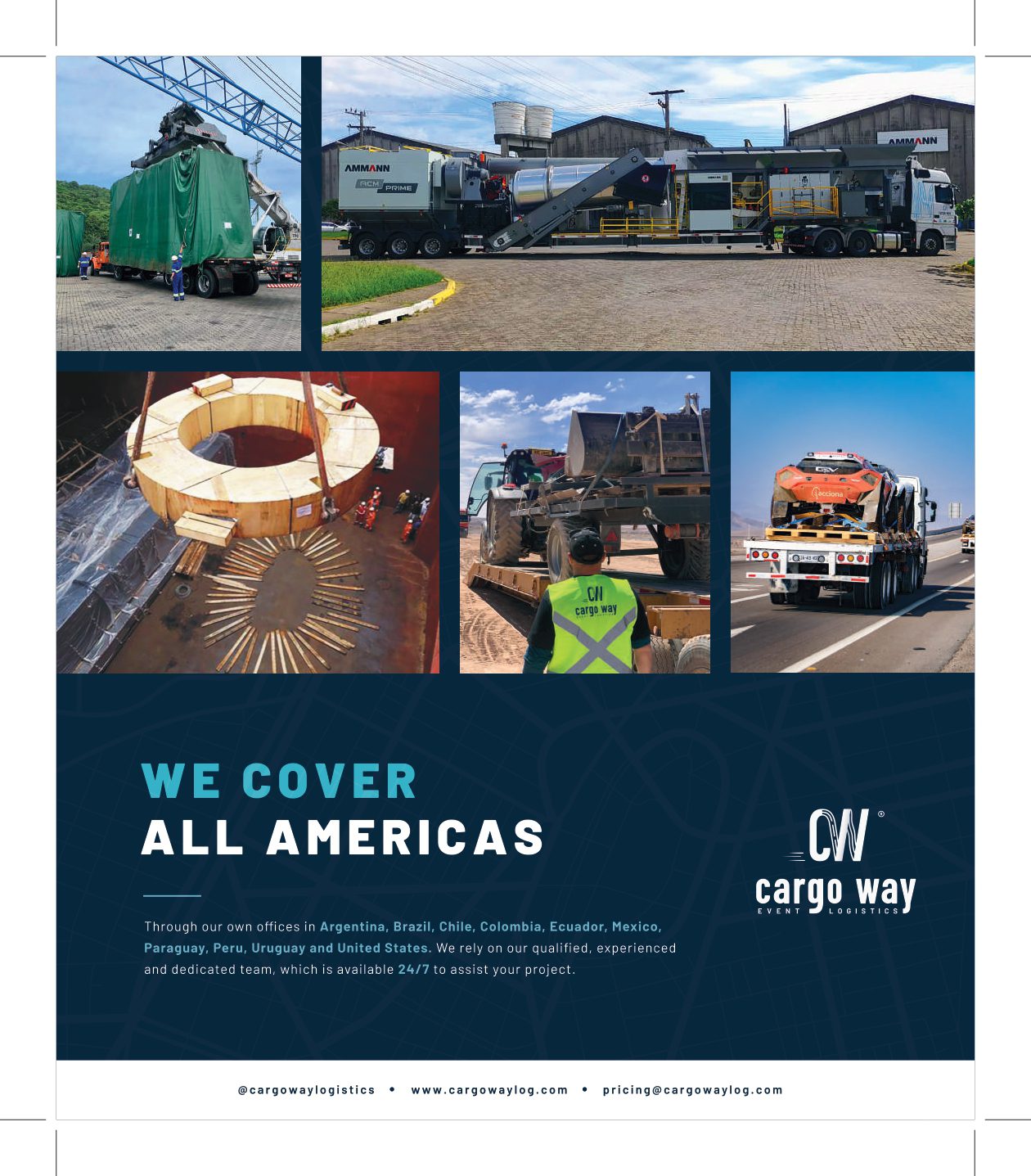

Latin America has the potential to be a global leader for renewable energy with enough existing and planned projects to meet regional net zero targets by 2030, according to a report by Global Energy Monitor. With more than 319 GW of utility-scale solar and wind capacity either announced, in pre-construction, or under construction, the region is positioned to grow its renewables capacity by more than 460 percent by 2030 if all these projects were to come online. The report said that Brazil, Chile, Colombia, and Mexico are currently at the vanguard for operating utility-scale solar and wind farms in Latin America, with a collective capacity of over 57 GW. But while Brazil, Chile, and Colombia continue to ramp up development, Mexico has stalled; even if all prospective projects were to come online, the country would only reach approximately 70 percent of its pledge to bring 40 GW of solar and wind online by 2030.

There has been strong growth in solar power, which accounts for 10 percent of Brazil’s energy mix, as does wind power. Hydropower currently contributes 52 percent of the total, meaning that only 28 percent still comes from fossil fuel sources. The new government of Lula da Silva has said it will stick with its green agenda and there is a backlog of power projects already auctioned for the coming two or three years.

Elsewhere in South America, mining activity has been strong in Chile, Peru and Argentina, while Venezuela and Guyana continue to offer great potential for Oil & Gas projects.

All of this is good news for the project forwarding sector and also reflects positively in the attendance of multiple GPLN delegates from Latin America at our upcoming AGM in June 2023, such as Argentina, Brazil, Chile, Colombia, Costa Rica, Dominican Republic, Ecuador, Mexico, Panama, Paraguay, Peru, Uruguay and Venezuela.

We are very pleased to announce that we have now reached over 200 GPLN attendees for our AGM at the Hilton Hotel in Rotterdam (June 3-5, 2023) and matched the record attendance of our 2018 conference in Bremen!

Our renown Heavy Transport and Lifting Seminar is also well booked and scheduled just after our meeting on June 6, 2023 at the same venue. This technical course is open for non-members and has still a few seats left. All relevant details about these events are published on our dedicated pages of our website.

Furthermore, both GPLN events can be combined with Breakbulk Europe which is scheduled from June 6-8, 2023 at Ahoy Convention Center in Rotterdam.

GPLN will exhibit at this event and has secured a prime location in the main hall with a 36 sqm booth which is the equivalent to 4 regular stands. 12 GPLN member companies will share our booth, namely (in descending order): Wirtz Link Service/China, transmaritim international/Germany, JSL Global/Qatar & Oman, Iscotrans/Italy, ITM Projects/Mexico, Falcon International/Canada & America, Expo Freight/India, CTC Logistics/Dominican Republic, Brelog/Germany, Balkonta/Lithuania, AZKA Shipping & Logistics/Iraq and Agence Maritime Mohab/Tunisia.

We are looking forward to your visit at our GPLN booth # 1A20 in Hall 1.

Best regards,

Your GPLN team

Universal Transport are flexible in all road conditions

GPLN member Universal Transport from Germany recently used two truck combinations to transport a carriage from the port of Bückeburg into the city center of Minden. Even though the route was only 20 kilometers long, the 40-tonne freight had to change modes of transport just before it reached its destination.

The reason for this were two obstacles precisely: A bridge, which would only allow usage of a lower trailer of the Universal transport fleet and the narrow entrance to the destination, which could only be passed with a significantly shorter semi low-loader. Two mobile cranes lifted the carriage in Minden off a 41-meter-long tank bridge onto a 31-meter-long special semi low-loader in order to be able to master the last few meters.

Of course, the reloading in Minden was not the only change on the long round trip of the carriage, which is produced in India and destined for the Indian market. The carriage arrived by seagoing vessel at the port of Antwerp in Belgium initially, where it was loaded onto an inland waterway vessel and then onto the road in Bueckeburg. In Minden there is a special climate chamber which put the carriage through its paces before returning in February.

Thanks to the flexibility and the fleet of Universal Transport, this challenge could also be solved. The necessary traffic control measurements were taken over by StB Verkehrstechnik. These included setting up a no-stopping zone along the route and blocking an intersection for allowing the changeover.

Tiel Logistics, Best Global Logistics and Hannational Shipping join forces

GPLN members Tiel Logistics and Best Global Logistics from The Netherlands and also Hannational Shipping from China joined forces for consolidating cargo and delivering it to China by airfreight. For a respected customer of Tiel Logistics, Tiel Logistics consolidated 14 crates, which were actually divided into 6 shipments to the warehouse of Best Global Logistics in Amsterdam for sending it with one flight to Shanghai Airport. From there Hannational Shipping took care of the DAP deliveries.

Tiel Logistics convinced their customer to do it this way, in order to save a lot of money. Of course, it had to comply within the delivery period. 6 shipments, became 1 shipment with 14 crates with a total of 8,146 kg.

Scope of work: several pick-ups from loading addresses, export documentation, airfreight and DAP deliveries.

This is a perfect example of the advantage of being part of the GPLN Projects Network, working together as a team! Because of this circumstances we can all work with trusted partners and give our customers an excellent service.

|

New GPLN Members / March – April 2023 |

||

| Brazil | Itajai | Quantum Logistics |

| Korea | Seoul | Interfreight-engineering Co., Ltd. |

| Paraguay | Asunción | Wave Logistics |

| UAE | Dubai | Splendour Marine LLC |

| UK | Shepperton | Blaiklock International Logistics |

| UK | London | Comodality LTD |

| Uruguay | Montevideo | Wave Logistics |

| USA | New York | Welton Shipping Co., Inc. |

| Uzbekistan | Tashkent | DAS Freight Solutions |

Ground-breaking delivery of 70 feet long OOG Package

GPLN member M/s M. Amin M. Qaseem (Pvt) Ltd., one of the Pakistan’s premier customs consultants and one-window project logistics solution provider, is serving the trade and industry for over 5 decades.

In March 2023, MAMQ has contributed a remarkable achievement for Pakistan’s Heavy Lift Movement Industry by delivering successfully an Out-Of-Gauge Package (i.e., 70 feet long) to Diamer Bhasha Dam Project in Gilgit-Baltistan province, Pakistan via N-35 National Highway onto new Goldhofer’s Multi Axle Hydraulic Trailer. Scope of work: Under-hook receiving of OOG extra-long package, customs clearance at Karachi Port, transportation from Karachi Port to Diamer Bhasha Dam, Gilgit-Baltistan.

The N-35 National Highway connects Islamabad to Karakoram highway and is well known for its rugged mountainous terrain with narrow sharp turnings, road gradients, land-sliding and tunnels at M-15 Hazara Expressway besides other weather associated conditions.

This is the first of its kind “Out-Of-Gauge movement” from Karachi Port to Diamer Bhasha Dam Project in the history of Karakoram Highway, making the MAMQ a pioneer in the delivery of Out-Of-Gauge shipment on the roughest and uncharted terrains of Pakistan’s Northern Region.

Keeping in view the challenging task of delivering the extra-long package (i.e., 21.36 meter long) to Diamer Bhasha Dam via single track N-35 national highway, MAMQ first conducted the land route physical inspection survey from Port of Discharge in Karachi to the destination site in Gilgit-Baltistan with its professional workforce in order to analyze the route and adopting a strategy for safe transportation.

MAMQ feel privileged for its milestone achievement of delivering the OOG cargo in the extremely high-altitude rough terrain of Gilgit-Baltistan, which is considered as the most challenging and risky land route for abnormal size cargo movements in Pakistan.

NAKAMA complete CAT Mining Heavy Lift Project

GPLN member NAKAMA from Panama completed successfully a CAT Mining Heavy Lift Project from Chile to Panama and are thrilled to share this heavy lift project which was executed through a partnership between NAKAMA WWS and another agent. The project was completed in two charters, with NAKAMA WWS serving as the supportive agent of the agent in Panama.

The first part of the project was received at Manzanillo port on February 13th, 2023, followed by the second part on March 15th, 2023. The project showcased the commitment to delivering reliable and efficient logistics solutions for heavy lift industries.

The CAT Mining heavy lift project highlights the capabilities of NAKAMA WWS in executing complex logistics projects. We would like to thank all those who contributed to the success of this project, including our partners, clients, and team members. Without their support and hard work, this achievement would not have been possible.

We are excited to continue providing world-class logistics solutions to businesses in the heavy lift industry, and we look forward to future collaborations with our partners, taking on more challenging projects in the future.

M.G. INTERNATIONAL handle big project to Iraq

GPLN member M.G. INTERNATIONAL from Germany handled recently a big project consisting of a sulphur amine regenrator unit for a oil and gas project in Iraq.

They moved a a couple of heavy pieces by multi axle trailers from the site in Jebel Ali and shipped all cargo by breakbulk vessel to Iraq and again by multi axle trailers to the site. The weight per piece was up to 75 tons and a deminsion of 31m x 3,4m x 4,2m.

FLS Breakbulk haul on container ships

GPLN member and Dubai-based Fleet Line Shipping (FLS) has recently successfully loaded six breakbulk cargoes from Jebel Ali and Abu Dhabi to various overseas destinations on container ships

The company’s expert team worked diligently to ensure that the cargo was loaded safely and efficiently and the operation was executed without any issues. In addition, their in-house cargo lashing team has done the on-board lashing of freight for some of the complex loads. This accomplishment is a testament to the company’s expertise and dedication to customer satisfaction.

Total Movements move Concrete / Anode Coated Pipes

GPLN member Total Movements from India successfully moved a Shipload of Concrete, plus Anode Coated Pipes from India for a Prestigious Oil & Gas Project in South-East Asia. Shipping of the entire consignment of 16,000 freight tons / 3,900 plus pieces of pipes was handled by the team of Total Movements India for its Indonesia team. Our scope of work involved shipping the consignment from the load port on the west coast of India to the discharge port in Indonesia and unloading the consignment from the vessel. The Total Movements team in India and Indonesia collaborated closely to execute this project in a seamless manner, overcoming numerous challenges. Listing some of them: Requirement of the right vessel that could load all the cargo together in one go while at the same time fulfilling MWS requirements / Ensuring all safety parameters are followed during the entire operation, covering lifting, dunnage, stowage arrangements, ship stability, and so on / Inclement weather at the discharge port hampered the operations at different points in time / Synchronization between different stakeholders for different legs to ensure everything happens in a smooth manner.

However, our team’s unwavering resolve and agility helped us overcome these different challenges to satisfy our customers. The shipment was stored at the discharge port for some time, after which all the units were loaded onto the barges and delivered to the final project site in South East Asia. We would like to express our gratitude to all the stakeholders who supported us in making this shipment a huge success. Moving Cargo with Passion!

WRL delivers for clients despite backlogs and port congestion

|

GPLN member WRL from Australia continues to deliver for clients and global partners despite Biosecurity backlogs and unprecedented port congestion. Australia is currently experiencing significant port congestion, Biosecurity backlogs, educed and in some cases suspended shipping services due to a combination of factors, including increased cargo traffic, labour shortages and increasing requirement for Biosecurity intervention. These issues have led to delays and disruptions in the supply chain, causing frustration and additional cost to importers and end users alike. |

|

|

Despite these challenges, WRL Shipping Pty Ltd, a project logistics provider, based in Australia, remains committed to moving used equipment via import and export channels efficiently and with the upmost care. While the current situation has led to unprecedented backlog and congestion at Australian ports including shore side quarantine facilities, WRL Shipping Pty Ltd has been able to work through this adversity, overcoming and providing best outcomes for both its customers and global partners alike. The company has effective protocols for handling used machinery from origin through to final delivery. The team at WRL are dedicated to ensuring that all shipments are properly inspected and treated at origin and again at destination, working closely with both government departments and service providers to achieve smooth import processing. |

Kita Logistics hanlde sensitive project shipments

Kita Logistics from Turkey, a GPLN member for almost 20 years, has completed two sensitive OOG truck shipments last month.

First a CNC machine, loaded on a hydraulic trailer with flatbed assembly and moved by land from The Netherlands to Istanbul almost with zero clearance on the ground due to the height of the cargo. The transport was completed within 8 days

Second a disassembled helicopter from Lisbon, Portugal, to Ankara airport by land to be used for installation of electric cables on the mountains. The door to door transport took 9 days.

Protranser coordinates the delivery of various project cargo

|

|

© Protranser International Logistics Co., Ltd. All rights reserved

GPLN member Protranser’s team from China delivered 3 packages of tanks from Zhangjiagang in China to the jobsite in Leipzig, Germany, for a hydrogen plant project via Cuxhaven port in Germany. The dimension and weight of each tank was 3190*445*450cm and 103 tons.

Working scope included: picking up cargo at factory, delivering to Zhangjiagang port by truck, chartering Breakbulk vessel from Zhangjiagang to Cuxhaven, chartering barge from Cuxhaven to Leipzig and delivering to jobsite.

In this project, we met several challenges, such as during Spring Festival when the equipment was picked up in the factory, there was lack of truck drivers in the market because they desired to go home for a family reunion and our team need therefore to coordinate multiple modes of transport for these 31.9 meters long tanks from the factory in China to the jobsite in Germany, which is “door to door” service. But finally, we made it and delivered the equipment to the jobsite safely and on time.

Protranser delivered also a locomotive- and spare parts from Qingdao, North China to Mombasa, Kenya. The dimension and weight of the locomotive was 9.5*3*3.6m and 26.8 tons. The locomotive and spare parts were stuffed in 1*40’FR, plus 1*20’GP. Working scope included booking, stuffing and export customs clearance service.

Furthermore, they delivered a Cold Drawn Steel Bar and Cold Rolled Steel Coil from Tianjin in China to North America. The total volume was 23 packages,116’000 kg and 28 CBM. Working scope included port service in Tianjin and chartering service for the breakbulk vessel.

Protranser delivered also over 6’000 CBM of different kind of engineering vehicles to Madagascar for local mining projects. These cargoes were shipped in two lots, one lot was from Shanghai, and another one was from Lianyungang, North China, including excavator, loader, roller, grader, heavy truck, truck crane, refueling truck, distributor truck and so on. Working scope covered port service in Shanghai and Lianyungang and chartering service of the breakbulk vessel.

In another shipment they delivered 2 sets of transformers from their client’s factory in Wuhan in China to Lisbon, Portugal via Shanghai port. The weight of the main body was 32’850 kg. All cargo was shipped by container vessel. Working scope included pick up cargo from the factory by trucks, customs clearance service for export, stuffing cargo at the warehouse and seafreight booking service from Shanghai to Lisbon.

Finally, Protranser delivered mandrels bars from Tianjin in China to North America. The total volume was 19 packages / 178’243 kg / 68 CBM. Working scope was chartering te service of a breakbulk vessel.

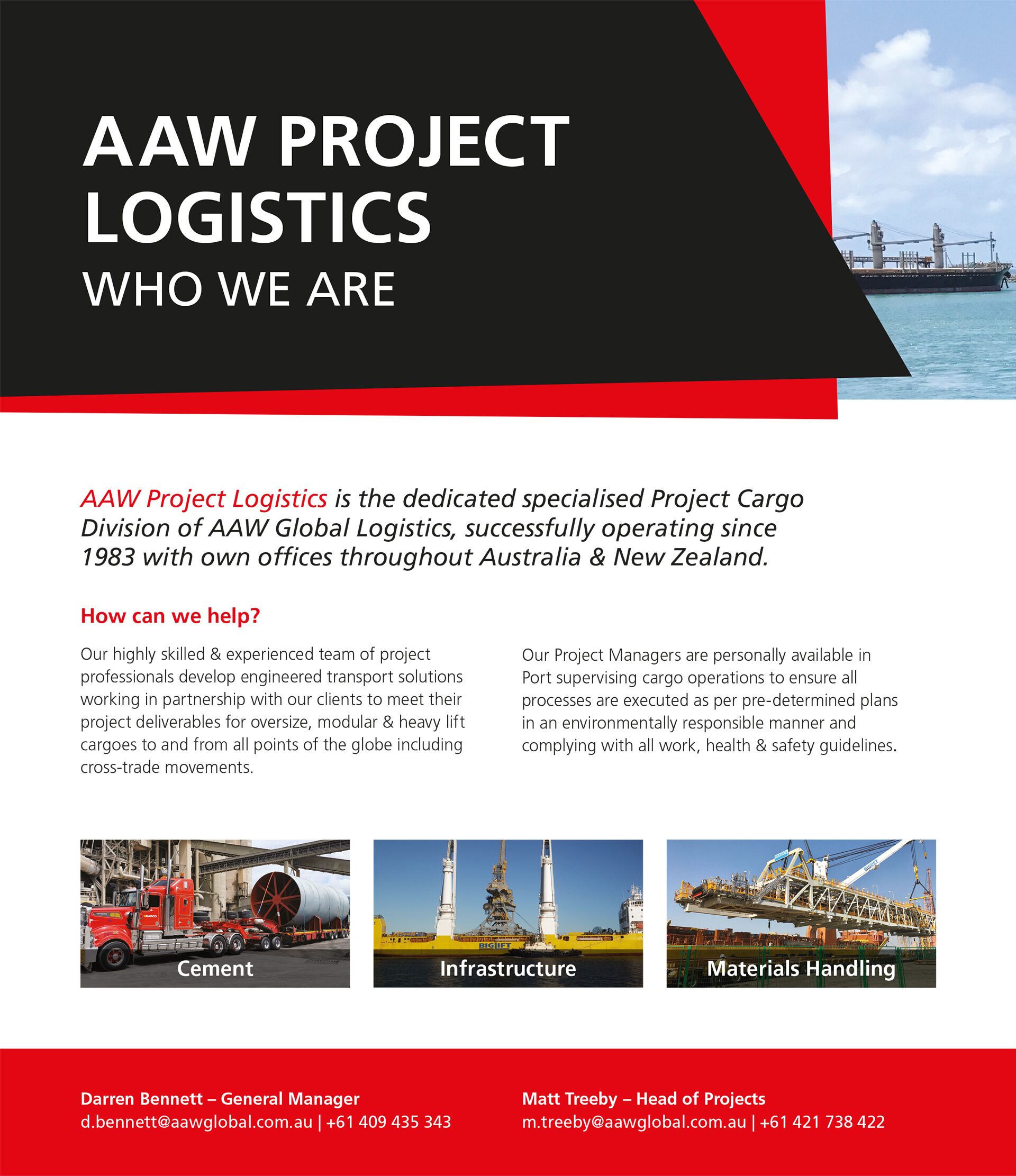

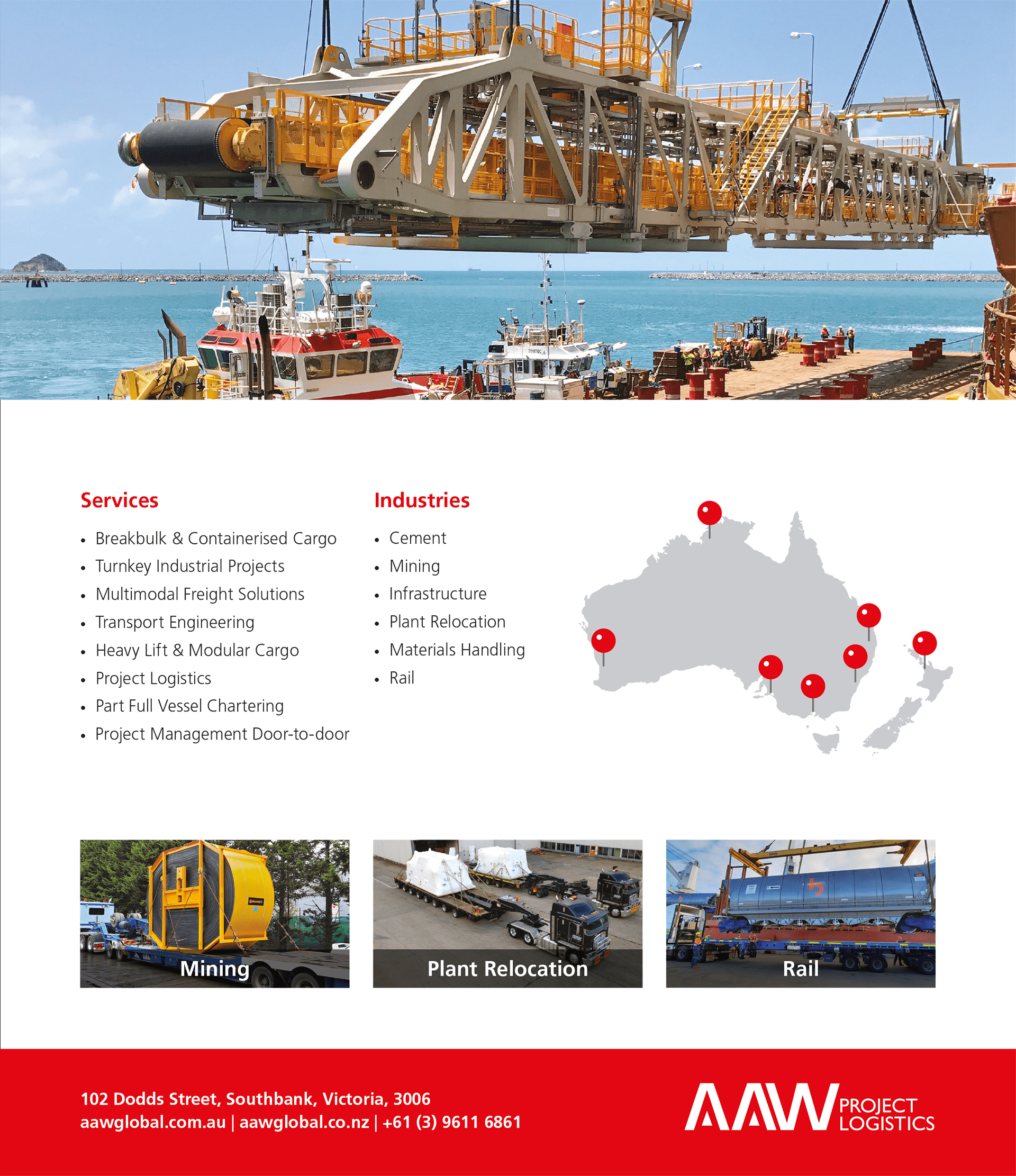

AAW PROJECT LOGISTICS ships Conveyor System and mining equipment

GPLN member AAW Project Logistics from Australia has successfully shipped a complete Conveyor System from FAS Dalian, China to DDP Port Hedland, Western Australia and cargo to be delivered to the nearby mine site. AAWPL were very well supported at POL by fellow GPLN member, Protranser International Logistics, China during the initial planning stage through to final loading at Dalian. A short transit basis last in / first out was a high priority for the customer and AAWPL chartering team sourced a perfect part charter solution for a Vessel arriving just days prior to all cargo being available for loading, this will enable the quickest arrival at the mine site.

The conveyor system is made up of 12 main oversize, over mass modules, 22 x loose items & 6 x 40’ containers, the largest piece @ 10.69mL x 10.43mW x 4.83mH and 69.50 mts, total shipment size was 5520 FRTS. With a direct & short transit from Dalian to Port Hedland of approx. 12days, it was necessary for AAWPL to estimate and plan a final delivery date to the mine site many weeks in advance of the cargo loading in China in order to secure the OSOM transport permits, Traffic Wardens & Pilots as required for the critical delivery to the Project Site.

Furthermore, we are thrilled to announce the successful movement of 74,000kg of mining equipment from Melbourne, Australia to Sao Paulo, Brazil via a Boeing 777, chartered by AAW Project Logistics on behalf of their customer.

This monumental task was undertaken by a team of highly skilled professionals from AAW Project Logistics who worked tirelessly to ensure that the equipment was transported safely and efficiently. The movement of such a large amount of equipment across continents required a great deal of planning and coordination, and we are proud to say that our team rose to the challenge.

The mining equipment was carefully loaded onto 21 PMC’s (platform pallets) using specialized equipment and was secured in place to ensure that it would not shift during the flight. Our team of experts also made sure that the equipment was protected from any damage that may occur during transit.

The successful movement of this mining equipment is a testament to AAW Project Logistics’ commitment to providing top-quality logistics services to our clients. They understand the importance of timely and efficient transport of equipment, especially in industries such as mining, where time is of the essence.

Polaris Projects – Big or Small we do it all!

| GPLN member Polaris Projects, project division of Polaris Shipping Agencies LLC, United Arab Emirates handled several interesting shipments which included also vintage cars, heavy construction equipment’s to over dimensional project cargos on special equipment’s (flat racks) etc. One of the interesting shipments were a few Volvo wheel loaders for one of our prime accounts which was dismantled suitably to be shipped in 40’ High Cube Open Tops destined for South America. Since our regular clients had a fixed budget for shipping, it was mandatory that the unit was carefully dismantled, tagged properly by each item for re-assembling once at destination which was carried out to the full satisfaction of our customer. |  |

|

| Our services included transportation of project cargo from port Sillamae to Enefit Power Auvere Ida-Viru, Estonia in December 2022 / Condensing Tower 33,60 x 5,46 x 4,66 m, 84,37 tons. Transportation of oversized cargo from port Sillamae to Enefit Power Auvere Ida-Viru, Estonia December 2022 / Heat exchanger 9,40 x 3,00 x 3,70 m, 58,2 tons.

Transportation of oversized cargo from port Sillamae to Enefit Power Auvere Ida-Viru, Estonia December 2022 / Extra Heavy Duty Oil Collection Vessel 11,60 x 3,80 x 4,00 m, 23 tons.Transportation of oversized cargo from port Sillamae to Enefit Power Auvere Ida-Viru, Estonia December 2022 / Pre-assembled Air Cooler 11,75 tons 8,00 x 2,60 x 3,60 m, plus 29 flatbeds in December. We used a total of 33 trucks. Goods were Made in Italy. We will continue confidently to participate in European energy projects in 2023. |

|

Star Shipping completes cross project with GPLN partner

GPLN member Star Shipping from Pakistan successfully nominated a project with its long-lasting partner in China, Protranser International Logistics from Shanghai.

Commodity: 26 Units Electric Car / Loading Port: Lianyungang / Discharge Port: Jebel Ali / Cargo Details: 26 packages / 28,470 kg / 212.089 CBM / 212.089 RT / Mode of transport: RORO Vessel / Scope of work: Ex-works to from factory to port.

Congratulating Protranser and its teams on a successful completion of the project! As you all are aware that it was one of the most prestigious projects for our company and you all have worked really very hard to complete it within the time limit and make it a great success for all of us. We highly appreciate all the efforts and time.

Transmaritim favour “flying cargo” in all ways

GPLN member Transmaritim from Germany is active in the Orient, but we are “flying carpet” only in the broadest sense, we favour “flying cargo” in all ways.

We are always looking for the best and most economical way for our customers. We have had a case recently where a shipment theoretically had to be stowed on a flat. The box was very voluminous, not very wide but in this case very heavy, 69 tons to be exact. Because of this, flat loading was almost impossible and also uneconomical. We therefore decided together with our customer for a RORO loading. We often use this type of shipment. Not only that the costs are often much lower, also the interfaces (stowage directly at the RORO terminal) are less risky.

Furthermore, tank logistics with a difference, this morning in central Germany. Yesterday still food in it, today on the way to South America.

1200cm x 350cm x 350cm, 6 tons, are the dimensions in this case. The load was secured by bearing shells.

We are often asked why we have chosen this profession. This picture basically says it all: new tasks and challenges every day. Today a container, tomorrow a turbine. There are no limits to the challenges. Our project team is looking forward to your inquiries and challenges.

MFC Extreme Projects on red alert

GPLN member MFC Extreme Projects & Events from UAE were on red alert when asked with short notice to manage the coordination, customs clearance and special transportation of a charter vessel at Jebel Ali Port.

The vessel contained 92 Earth Moving heavy plant vehicles weighing approx. 2689 tons, and due to time restraints the project required careful transport pre-planning and configuration of our open yard facility to ensure every inch of space was maximized and carefully mobilized into position.

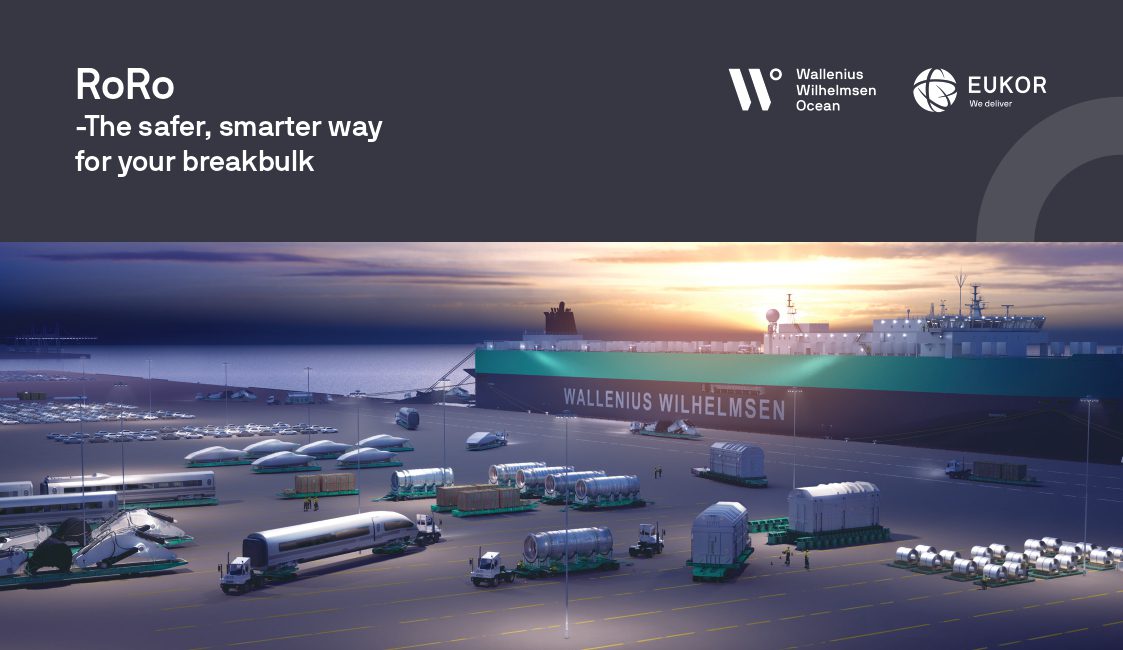

WW – What you need to know about the booming transformers market?

“Last year, everyone in the shipping industry, including our customers, faced major challenges due to port congestions, labor shortages, and general supply chain disruptions. And in times of hardship, it becomes clear who your real partners are,” says Carsten Wendt, a senior manager for high & heavy and breakbulk based in Bremen, Germany. “At Wallenius Wilhelmsen, we have to be very selective when our capacity is stretched and prioritize long-term contracts and partners.”

The transformers market is growing at an accelerated rhythm and, at a time when our industry is still facing major challenges, it’s difficult to keep up with the latest developments. So, what do you need to know? Why is the transformer industry booming? According to Wendt, one reason is the current shift in power generation, with high investments in power transmission due to increased demand for electricity. He also notes that in the US, production industries are on the move going east, from California to Texas, possibly due to inter-state differences in environmental regulations.

“We have also seen similar dynamics in Germany, where energy is produced in the north and consumed in the south requiring upgrades to the existing grid. This means many transformers are needed elsewhere, thus the need for transportation.

According to Market Watch, the forecasted prognosis for the large-capacity power transformer market is “poised for significant growth.” This is also the case for the US market. The average time for obtaining new transformers in the US has increased from two months period in 2021 to 12 months in 2022, according to News Scientist in an article published in March this year. Another reason why the North American market is particularly hot is the long-time under-investment in the aging grid. It leads to a growing demand for new transformers, another reason for the high demand for shipments of transformers from Europe,” Wendt says.

Wendt says that there are three important factors to think about:

Secure transport capacity, not only short-term but also long-term

Timely delivery of the transformers is key, as usually there are penalties for every transformer delivered on-site too late, so the frequency of sailings and transit time matters a lot. However, Carsten emphasizes that this isn’t always unavoidable. 2022 has been a challenging year also for Wallenius Wilhelmsen to keep a reliable schedule due to disruptions in the ports.

Make sure you pick a partner that has the technical capabilities (vessels and equipment) as well as the technical knowledge (engineering competence) to perform adequate transformer transportation. What should you consider?

With the rising demand for transformers, there are three types of vessels that compete in the transshipment space: 1) multi-purpose heavy lift carriers, 2) container vessels, and 3) roll-on/roll-off vessels.

The multi-purpose heavy lift carriers can take all kinds of weights, but they struggle to meet the demand in transit times and sailing frequency. The container vessels have the frequency and the transit times, but they struggle with access to the right equipment for the weight and the dimensions of the transformers.

“At Wallenius Wilhelmsen, we have combined the benefits of our roll-on/roll-off vessels and equipment, which are specifically designed for high and heavy cargo. We have flexible decks that can be accommodated many cargo sizes, we have extensive ramp capacity up to 500 tones, and have a fleet of over 5,000 trailers that are perfectly suited for transformers up to 220 tones providing safe and efficient loading and unloading. In addition, we have a team of experts who have experiences and the ingenuity to ensure that transformers are delivered safely and are stowed safely during ocean voyages. In fact, it is as if our vessels were designed specifically to ship transformers – the physical dimensions fit like a hand in a glove,” added Wendt.

Last year was super challenging for the industry, but we are glad that we could help our customers get their transformers to where they needed to go.

Inter American Cargo Group providing backup

|

GPLN member Inter American Cargo Group S.A from Argentina have been providing backup for many projects in the Oil & Gas and Mining industries, in line with big investments in these sectors. Using its background, vast experienced and full skills to achieve the most challenging tasks Inter American Group had an opportunity to handle 2 sets of 65 tons compressors, plus 180m3 coolers to the final destination in the Vaca Muerta oil fields. |

SCT logistics JSC handle many OOG projects

GPLN member SCT Logistics JSC from Vietnam handled recently many OOG projects in the Northern & Southern regions of Vietnam. One export shipment in the north was based on FCA terms from Hai Phong to Burnie, Australia. There were 2x 40 OT, plus 1x 4 FF successfully delivered from door by international sea transportation with dimensions of 110cm x 23cm x 26 cm, 110cm x 23cm x22cm & 112cm x 48.50 cm x 25cm. In spite of the stuffing and lashing being under the shipper’s account, we still assisted them to secure the cargo safely and issued also a lashing certificate for the Flat Rack Containers before allowing them to load on board to the carrier.

In the Southern part of Vietnam, SCT Logistics handled EXW many OOG packages from HCM city to Laem Chabang in Thailand on 3×40’FR OOG with dimension in turn 82cm (L) x 35.50cm (W) x 11cm (H), 110cm(L) x 37cm (W) x 37cm (H) & 91cm(L) x 25cm (W) x 35cm (H). We offered also a solution at a reasonable cost to the client for a combined task of stuffing the cargo at the factory and the port.

Furthermore, SCT Logistics arranged also recently an import shipment for a motor 9800 KW, 4P, 11000V, 585.9A, 03 PHASES, 50HZ. This project was a re-import from Busan in Korea to Hai Phong in Vietnam after they had finished repairing it in Korea. The volume of the motor was 4.8 (L) x 3.8(W) x 3.6(H) m & GW: 38 tons. We gave the client many different options for international sea transport. However, the optimal solution was tackle / tackle (bulk cargo on the container vessel) for this shipment. This option was not only saving cost at the Korean side, but also on the Vietnam side for the local charges once we received the cargo alongside the vessel.

Interfreight-engineering deliver 56-ton surface condenser

GPLN member Interfreight-engineering Co., Ltd (hereafter “IFE”) from Korea recently successfully delivered 56 tons of surface condenser with a dimension of L11.7m x W3.2m x H4.08m from Masan, Korea to Gresik, Indonesia for Chiyoda’s Manyar Smelter Project (MSP).

IFE has been cooperating with Chiyoda corporation since the beginning of IFE’s establishment. Not only heavy items, but also ocean and air shipments are being transported by IFE for MSP.

Agence Maritime Mohab handles heavy pieces

GPLN member Agence Maritime Mohab from Tunisia received 2 OOG pieces at the Rades port, each one weighting 43 tons and 48 tons respectively.

The cargo arrived with Mafi’s and they prepared the same day the unloading and reloading into trucks. This job required to mobilize a crane and lowboys on the date of arrival to perform delivery on time.

You can always count on MOHAB’s experienced team in Tunisia for a good job and and in-house engineering.

DAS handle steel structures to factory in Magnitogorsk

GPLN member DAS Global Logistics from Russia handled recently a whole vessel at Nakhodka port (located in the extreme southeast of Russia on Nakhodka Bay off the Sea of Japan) to a big factory in Magnitogorsk which is over 7’000 km away (industrial city in Chelyabinsk Oblast, on the eastern side of the extreme southern extent of the Ural Mountains by the Ural River).

The commodity was steel structures. There were OOG, as well as IG cargoes.

DAS is systematically handling such vessels in Vladivostok and Nakhodka gateways with further delivery to any region in Russia. They are working with every terminal in those locations which allows them to be flexible with vessel berthing and to arrange “much faster berthing” which saves time and money.

Greenshields Project Cargo ship 45 feet containers

GPLN member Greenshields Project Cargo from Italy handled recently a project cargo shipment. In this case the focus was this cargo shipped by 45 feet containers.

Indeed these units are not usual for maritime cargo service. They were stuffing these containers on behalf their customers/partners/agents and had to use this kind of equipment because of the packages with an extra lenght of 12,00 m upto 13,50 m.

Greenshields just shipped 7×45 feet units containing pipes and further shipments are expected in a short time destined to the Far East. Special lashing was also arranged by themselves in accordance with the clients’ and carriers’ requirements. Furthermore, the survey report was duly issued and released and everything was planned as expected by their own ISO9001 SQ Project Tests.

We would also like to take this opportunity to thank sponsor to thank all of our sponsors for their great support or our upcoming 18th Annual General Meeting in Rotterdam. Please see below the names of our supporters.