A word from GPLN: Newsletter Issue 93 / July-August 2023

Dear Reader,

Good news for GPLN members specializing in the wind offshore industry.

The EU installed 1.4 GW of new offshore wind capacity in the first half of 2023. According to WindEurope, this is below the level needed to reach the bloc’s energy and climate targets. It stated that the EU, on average, should be building 11 GW of offshore wind capacity per year between now and 2030 and noted that last year, investments were delayed over the regulatory uncertainty caused by abrupt government interventions into power markets. However offshore wind energy is getting a boost in Lithuania, with the government recently selecting a consortium to develop a 700 MW project approximately 30-36 km off the country’s Baltic Sea coast. Plans to hold a second wind auction later this year are already under way. Similar models have been rolled out across European wind auctions. Germany, for instance, announced the results of its biggest offshore wind auction also recently with 7 GW of new capacity awarded, based on the same model. In general, the situation in Europe has improved this year with six big projects totalling 5 GW of new capacity.

As announced earlier, our next year’s GPLN Annual General Meeting will take place from May 18-20, 2024 again in The Netherlands, followed by our renown Heavy Transport and Lifting Seminar on May 21, 2024. This time we have selected the seaside city of The Hague (Den Haag) where both GPLN events will take place. Please refer for more details to our dedicated websites.

Furthermore, both GPLN events can be combined with Breakbulk Europe which is scheduled from May 21-23, 2024 at Ahoy Convention Center in Rotterdam.

GPLN will exhibit at this event and has secured again the same prime location in the main hall with a 36 sqm booth which is the equivalent to 4 regular stands.

From September 26 to 28, 2023 we will exhibit at Breakbulk Americas which takes place in Houston, Texas. This is the region’s largest trade event for the project cargo and breakbulk industry with over 5’000 attendees and 270 exhibitors. Following GPLN members will join our GPLN booth and are available for meetings: Expo Freight (EFL Global)/India, FOX Project Logistics/Brazil, Global Shipping Services/USA, Green Worldwide Shipping/USA, ITM Transportation/Mexico, and Nu-Era Logistics/Canada.

We are looking forward to meet those who join or visit our GPLN booth #J02 at George R. Brown Convention Center during this event.

Best regards,

Your GPLN team

A Multimodal, Breakbulk Journey by Green Worldwide Shipping

The efficient and secure movement of heavyweight and oversized freight presents challenges for many customers. A client recently contacted Green Worldwide (a GPLN member from USA) to provide project oversight for an oversized, overweight tile machine press for a manufacturing facility. Green Worldwide Shipping’s “boots on the ground” proactive approach to project cargo transport ensured the safe, efficient transit of oversized cargo.

The cargo, a tile manufacturing press, weighing an impressive 127.5 tons, was no small feat to transport. Green Worldwide managed its transit from the Port of Charleston to its destination in rural Tennessee. The tile press was substantial, measuring 7,60m in length, 3.65m in width, and 2,50m in height, and qualified as a wide load, necessitating meticulous planning and execution to ensure its secure and damage-free transit.

Green Worldwide moved this expensive commodity with careful planning, route analysis, and close collaboration with government agencies. A multimodal approach contributed to the seamless transit of the tile press. The machinery began its journey in Italy on an ocean vessel for a transatlantic voyage to the Port of Charleston. Green facilitated transloading the machinery from an ocean vessel to a barge that traveled to the Port of Atlanta. Once in Atlanta, Green Worldwide managed the rigging crew to ensure proper freight transfer from the barge to a heavy haul truck for the final leg of its journey to its new home in rural Tennessee.

A Green Worldwide Project Cargo expert was onsite at every stage of the journey, overseeing the handling of the wide load that required precise adjustments, including hydraulics, leveling, and secure fastening of the machinery, onto a dual-lane 17-axle truck bed. Green Worldwide Shipping’s “boots on the ground” approach, rigorous project management, and meticulous planning ensured the secure transport of this heavyweight commodity.

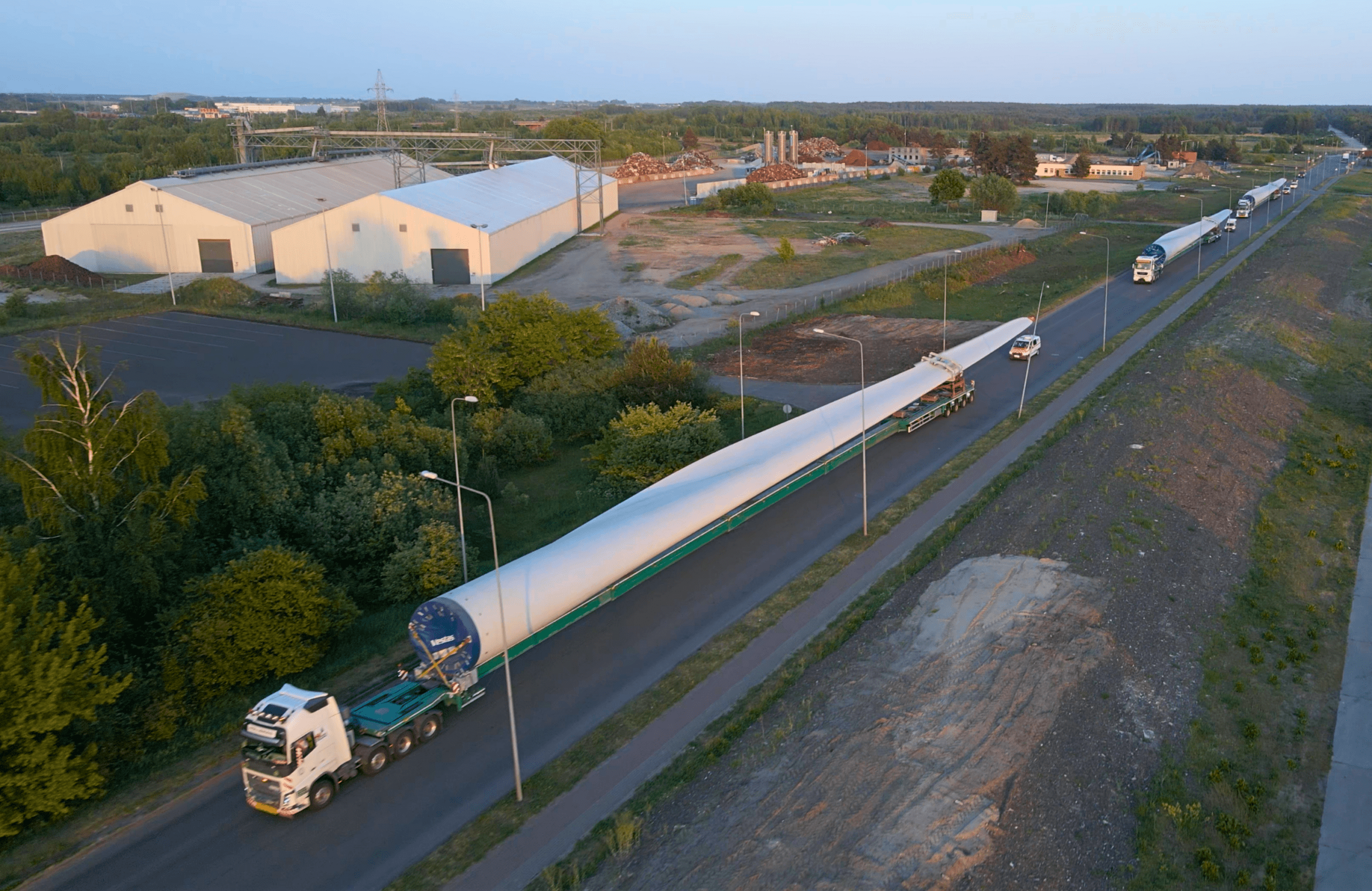

Holleman Romania’s “Akmene One” Transport

GPLN member Holleman from Romania is supporting green energy with innovation and collaboration. In the realm of impressive logistics, a standout project has been shaping up, orchestrated by Holleman Romania – the “Akmene One” transport venture. It’s not just a logistics matter; it’s a reflection of their commitment to impeccable transport. From working to careful planning, this project has become a source of pride, and here’s why.

The project started on April 18, 2023. The goal was to carefully transport 12 Vestas V162 Enventus wind turbines. Fast forward to September 7, 2023, and the project is estimated to be completed, leaving its mark on the renewable energy landscape.

Behind the scenes, the project tackles the challenge of moving massive components. We’re talking about turbine blades measuring 80 meters long, 4.6 meters wide, and 3.5 meters high, each weighing 28 tons. But that’s not all – handling turbine tubes, ranging from 14 to 33 meters long, with diameters of 4 to 6.4 meters, and weights between 72 and 97 tons, adds another layer of complexity. These parts travel in trailers and tractors spanning 40 to 90 meters, with total weights ranging from 90 to 163 tons.

From the port of Klaipeda, Lithuania, to Akmene, the trip covers a distance of 250 kilometers passing through a variety of terrains and following regulations. Holleman Romania excels in overcoming both the challenges and the various regulatory and environmental obstacles making sure everything goes smoothly.

The project’s timeline is impressive, in terms of efficiency. The transport maintains its schedule impeccably.

The “Akmene One” project showcases the future of renewable energy logistics. Through collaboration, Holleman Romania achieves sustainability and innovation. As we are near the end of the project, it serves as a reminder that when individuals with a shared goal come together, they have the potential to accomplish anything, paving the way for an environmentally friendly world.

PROTRANSER handles various project cargo

GPLN member Protranser from China delivered recently equipment for a water turbine from Tianjin, China to Turkey. The total volume was over 1000 CBM and the max weight of one unit was 70 tons. Working scope included picking up cargo from the factory, port service and chartering service for the breakbulk vessel.

They delivered also another equipment for a water turbine from Tianjin to South Asia. The total volume was 50 packages / 128,424 kgs / 213.72 CBM The weight of the heaviest piece was 25 tons. Working scope included picking up cargo from the factory, delivering it to Tianjin port by truck and chartering of the breakbulk vessel.

Protranser handled a set of Roller Hearth Furnace from overseas to Wuxi city, Jiangsu province via Shanghai port. All cargo was stuffed in 10 containers, including: 1X20GP + 3X40HQ + 1X20FR + 5X40FR. Working scope was import customs clearance service, delivering the cargo to the factory in Wuxi by air cushion vehicles and returning the containers back to Shanghai port.

Furthermore, Protranser delivered 30 sets of dump trucks from Durban, South Africa to Kolwezi, DRC in the first half of 2023. The total volume was over 4500 CBM. Although there was lack of abnormal trucks (ABN) in the market, they finished successfully the work for each lot in 33 days.

Their team handled also “Door to Door” service for 19 tons of precision instruments from Germany to Nanjing, China. The volume of the cargo was 8 packages /18940 kgs. The cargo was a testing machine for a powertrain part of a passenger car.

They prepared after the full preparation packing the material and an auto crane and a crew for packing in the factory in advance, such as communicating with the shipper, measuring cargo data on site etc. And their client took their advice to split one piece of cargo, adjusting the height from 2.94m to 1.9m in order to save cost and meet the requirement of the carrier. Since the direct flight from Frankfurt to Shanghai was not operated yet during that time and considering cost and time, Protranser offered an alternative solution: delivering the cargo to Frankfurt airport by truck, from Frankfurt airport to Wuhan airport by air, and finally delivering the cargo from Wuhan to Shanghai by truck. The cargo arrived in the factory in Nanjing after having arranged the import customs clearance in Shanghai and was delivered safely and on time.

Furthermore, Protranser’s team delivered 2 pieces of cable reels from Italy to China by sea. The weight of each piece was 45 tons. They picked up the cargo from the factory in Italy and delivered it to Genoa port with a road permit which they prepared in advance (usually it would take at least one month to apply). The cargo was loaded and lashed properly on to the container vessel as breakbulk cargo (BBK) and was shipped safely and on time to Qingdao port in China.

Finally, Protranser delivered since the beginning of 2023 over 100 mining trucks and 10 excavators (model 900D) from Durban, South Africa, to the jobsite in Lubumbashi and Kolwezi, DRC via Zimbabwe and Zambia. The gross weight of each excavator was around 93.89 tons, which was spillted into 10 pieces because the main body had 32.4 tons. In order to save cost for the client, they offered the solution of 2 excavators per lot. The weight and dimension of the mining trucks was 40 tons, measuring 9,374 *4,338 *4,496 meters.

CSS handle over-dimension and heavy weight cargo

|

|

GPLN member Consolidated Shipping Services (CSS group) Industrial projects experts from UAE, along with the Northern Emirates project team (CSS Kingston) is delighted to share the successful loadout of 3 over-dimension and heavy weight cargo, comprising of a crane king, main boom, and knuckle, from Jebel Ali to Brazil for one of our premium clients. Our scope of work covered a full range of services, making this a truly comprehensive turnkey solution, with a suitable carrier and vessel selection, meeting packaging vessel requirements and heavy haulage with escorts and CSS boots on the ground operation. One of the critical aspects of this operation was the strict deadline set by the client, who needed a vessel option with best transit time and CSS project experts therefore assisted the client in finding the most suitable solution. Throughout the entire project, CSS project team addressed all potential risks considering the best HSE practice and implemented risk mitigation strategies. CSS project team dedication to accuracy and attention to detail and fantastic teamwork ensured that the project was completed successfully.

|

New GPLN Members Issue 93 / July-August 2023 |

||

| China | Tianjin | Tianjin Viewtrans Co., Ltd. |

| Israel | Ashdod | Ultimate Business Logistics Ltd. |

| New Zealand | Auckland | Mainstream Global Ltd |

| Portugal | Porto | Noatum Project Cargo Portugal |

| Singapore | Singapore | ASPRESS Shipping (S) Pte Ltd |

| Taiwan | Taipei | FSL Projects & Logistics |

| United Kingdom | Bradford | Zenith International Freight Limited |

CKB handles Mobilization of Transformers

GPLN member PT Cipta Krida Bahari (CKB Group) from Indonesia has completed a project logistics service for the mobilization of 2 units of 90 MVA Transformers owned by PT Vale Indonesia Tbk in Soroako, South Sulawesi.

The mobilization of these two units of 90 MVA Transformers weighing 65 tons, started from Laem Chabang, Thailand to PT Vale Indonesia, Malili, South Sulawesi, Indonesia. The cargo was mobilized from Balantang Port, South Sulawesi to Larona Hydroelectric Power Plant using 3 units of Prime Movers, 1 unit of Whell Loader and multi–axle CKB Group with extreme terrain conditions such as when entering the intersection of Larona Hydroelectric Power Plant or in the process of cargo crossing the bridge with a safety limit of 40T.

A prudent survey, operating plan analysis, routes, timeliness of operation and type of transportation are key factors for successful delivery, which are part of CKB Group’s solutions to meet customer expectations. With CKB Group’s extensive experience of more than 2 decades in handling various logistics projects, the mobilization of these 2 units of 90 MVA Transformers was successfully and safely delivered on time.

MAMQ handles Heavy Steam Turbines

GPLN member M/s Muhammad Amin Muhammad Qaseem (Pvt) Ltd. (MAMQ) is one of Pakistan’s premier customs consultants and one-window project logistics solution provider, serving its clients and country for over 4 decades.

Recently, MAMQ has handled and delivered 2 units of Steam Turbines, weighing 70 tons each, with a dimension as 5.90 *4.86 *3.53 meters, on its Goldhofer’s Multi-Modular Hydraulic Trailers from Port Qasim, Karachi to the Etihad Sugar Mills Site at Rahimyar Khan, Punjab, in safe and sound manner.

After the delivery to their destination site, the Steam Turbines were successfully unloaded onto temporary steel frame foundations by using 2 different capacity certified mobile hydraulic cranes.

MAMQ is glad for its achievement of delivering the heavy-lift cargo with sophisticated handling and safe unloading in open space at the Etihad project site.

Fleet Line Shipping moves compressor

Dubai/UAE-based GPLN member Fleet Line Shipping (FLS) has successfully transported a massive VRU compressor package to the Dubai Dry Dock, weighing 88 tons with dimensions of 11.5 x 6.9 x 7.6 meters.

It involved a multi-step process, starting as Break Bulk cargo received from a container ship; Team FLS meticulously orchestrated the compressor loading onto a FLS chartered Landing Craft. This transition required seamless coordination and careful planning to ensure the safety and security of the valuable cargo. FLS’ in-house ISO, QHSE, and a DP World-approved cargo lashing team played a pivotal role in meticulously securing the compressor on board. The compressor was successfully delivered to DDD.

|

|

Eastship’s Key Contributions in Transformational Project

Revamping Romanian Railways: GPLN member Eastship is part of the modernization of the railway between Sighișoara and Brașov marks a transformative milestone in Romania’s transportation landscape. In 2020, CNCF CFR SA and the rail works consortium (comprising Alstom, Arcada, Aktor, Euroconstruct Trading 98) signed an essential contract to undertake the upgrade of the Brașov-Sighișoara railway, covering an extensive 128-kilometer stretch.

The project entails a range of essential components, including the rehabilitation of three stations: Racoș, Mateiaș, and Ormeniș, as well as the construction of two overpasses and the development of seven bridges. Additionally, the installation of ten culverts and three viaducts will ensure proper water drainage and provide elevated passages for trains across challenging terrain.

At the core of this ambitious endeavor are two monumental tunnels, measuring 7 and 5 kilometers each, respectively. To accomplish this feat, state-of-the-art Tunnel Boring Machines (TBMs), affectionately called “cârtițele” or moles, have been deployed.

These colossal machines are capable of advancing 15 meters per day, and will work 24/7, 6 days a week. So, the 7km tunnel will be completed in 18-19 weeks and the 5km one in 14-15 weeks. The excavation of two double tunnels: the seven-kilometer Ormeniș gallery and the five-kilometer Homorod gallery is poised to be an extraordinary accomplishment.

The first TBM has been delivered and has started working on 15 June and of the remaining 3, 1 has just been delivered and will start work on 30 August. The last ones are scheduled to be delivered by the end of the year.

As a logistics partner for this project, EASTSHIP has played a pivotal role in transporting the massive TBMs to their designated locations. This has been a significant challenge as the transport took place on DN1, particularly on the Prahova Valley, one of the busiest roads in Romania. Due to the width of some parts, sections of the road had to be fully closed to allow the convoy to pass safely.

Despite the complexities of navigating winding mountain roads, our experienced team at Eastship efficiently and precisely handled the transport of the TBM parts for over 500 kilometers.

Once completed, the upgraded railway section between Sighișoara and Brașov will facilitate train speeds of up to 160 kilometers per hour, reducing travel time between the two tourist cities significantly. Presently, trains navigate this stretch at a modest pace of 40 kilometers per hour.

As proud contributors to this landmark railway modernization project, Eastship remains committed to ensuring the smooth delivery and execution of critical infrastructure developments that will shape the future of Romania’s transportation network.

Total Movements handle multimodal transportation

GPLN member Total Movements from India arranged a multimodal transportation of 5 transformers and their accessories from the supplier’s factory in Indonesia to the destination port in Australia. This consignment of about 1100 FRT was moved to two distinct destinations in Australia. Transportation from the supplier’s works to the load port, customs clearance at the load port, and shipping from the Indonesian port to the Australian discharge ports were all encompassed in our scope. The difficulties this movement confronted and overcame comprised:

1. As this consignment needed to arrive on schedule, we chartered a vessel that could accommodate the customer’s suggested laycan.

2. Despite the fact that the destination ports were extremely congested, our team was able to berth the cargo promptly upon arrival, thanks to constant liaison with the relevant parties.

3. Ensuring all safety measures as we experienced harsh weather during the loading procedures

Our team overcame every obstacle that stood in its way by working relentlessly and meticulously. We would like to extend our gratitude to everyone who supported us making this shipment a big success.

3PL Ship Conveyor Line Elements to USA

|

|

GPLN member 3PL has successfully completed the delivery of 7 oversized conveyor line elements (who were made in Latvia) from Latvia to Lithuania, port of Klaipeda. The elements had a dimension of 4,7m in width and a height of more than 4.5m. 3PL arranged the required permits, pilot cars and police escort. In the port of Klaipeda, the 3PL port office was supporting the customer with all port needs such as lashing, securing, loading on FRs, etc. before the shipment to USA.

Star Shipping delivers OOG and Heavy Gas Storage Tank

GPLN member Star Shipping’s heavy haulage team from Pakistan loaded recently an out-of-gauge heavy gas tank from DHA Lahore onto multi-axle hydraulic trailers and delivered it to its destination in the Sehwan district, the south-western part of Sindh province in Pakistan.

The work-scope included the receiving, handling and transportation of a 50 plus tons LPG storage tank with a dimension of 15.00 *3.00 *4.00 meters. The whole heavy haulage operations from ex-factory to the destination was carried-out according to the ISO 9001-2015 QMS standards wherein the safety of human resources, cargo and carrier equipment were prioritized and the shipment was delivered to it destiny within the provided lead-time with utmost safety. Star Shipping is proud of their technical team’s achievement for the successful delivery across a distance of 1,000 km.

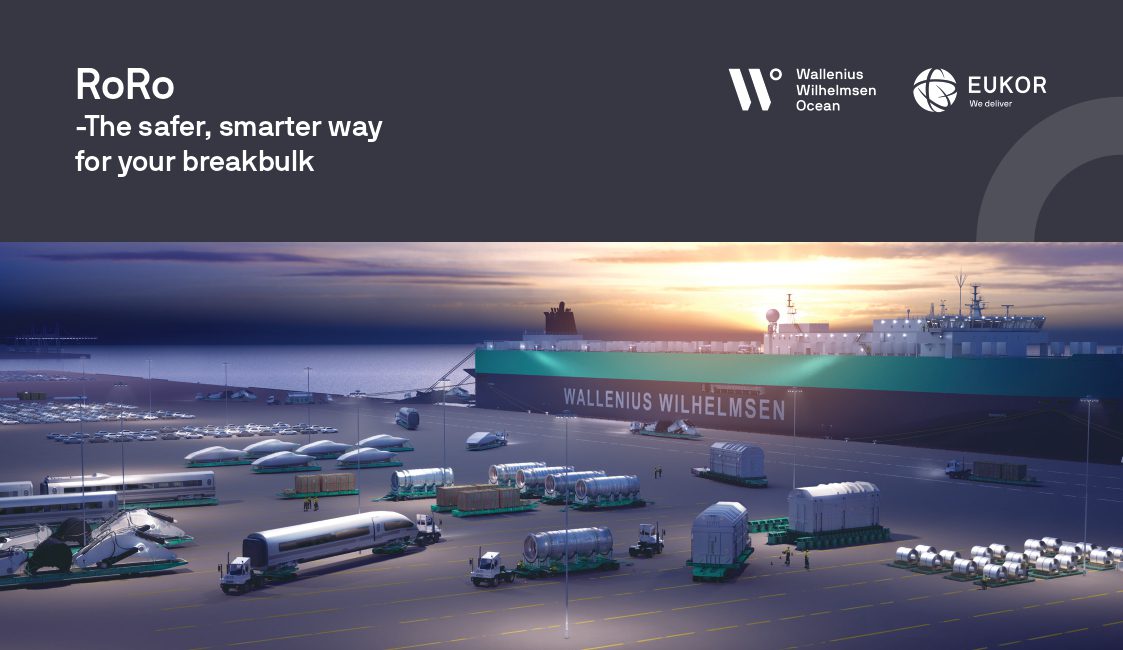

Wallenius Wilhelmsen signs letter of intent for four firm and eight optional vessels

Wallenius Wilhelmsen ASA has signed a letter of intent for delivery of four 9,350 CEU methanol-capable and ammonia-ready vessels and individual options for an additional eight vessels. The four vessels will be delivered from mid-2026 and onwards by Jinling Shipyard (Jiangsu).

“We are securing our position as our customers’ first choice in shipping and delivering on our strategy to provide a net-zero emission free end-to-end service by 2027,” says Xavier Leroi, EVP & COO Shipping Services Wallenius Wilhelmsen.

Wallenius Wilhelmsen will be transformational in its efforts to combat climate change. All new investments shall contribute to the net-zero agenda. As a result, the vessel class will be named “The Shaper Class,” showing the company’s commitment to this ambition.

“There is an urgent need for our industry to transform over the next couple of years. As a company, we are determined to shape this industry and lead the way to capitalize effectively on changing circumstances, as we grow with customers and partners sharing our journey,” says Lasse Kristoffersen, CEO and President Wallenius Wilhelmsen.

“We believe that metPros hanol is the fastest way to net-zero emission, and the ordered vessels can upon delivery use alternative fuel sources such as methanol. The vessels will also be ammonia-ready and can be converted as soon as green ammonia becomes available in a safe and secure way,” says Leroi.

Wallenius Wilhelmsen is the world’s largest RoRo vessel operator and has set a strategy to maintain a fleet of 125-135 vessels. New vessels are an integral part of the fleet strategy, and the key to accelerating the journey towards net-zero emissions.

“To secure our number one position, we will continue to deliver great services with a competitive fleet, offering sustainable supply chain services both on land and at sea. We are already partnering with our customers on reducing emissions through biofuel. With the new vessels, we can accelerate our operations towards net-zero. This requires new and more expensive fuels and we are committed to securing this together with our customers as soon as it can be made available,” says Leroi.

Mega Online handle Heavy Press

GPLN member Mega Online from Spain recently loaded a press weighting 83 tons from Castellon to Bilbao port in Spain, to the final destination in Brazil.

They coordinated the cranes and loading from the factory to the truck, reception at the Bilbao port and arranged also sea freight to the Port of Paranaguá which is one of the main ports of Brazil and Latin America and the second largest port of Brazil in tonnage.

A famous and well-known factory in Spain has renewed their plant and one of their press will be installed at their own factory in Brazil.

MFC manage operation for Earth Moving Vehicles

The Project & Events team of GPLN member MFC Extreme from UAE got awarded a new project to manage the stevedoring operations of a charter vessel containing 75 Earth Moving Vehicles and parts with a GW of 2,420 tons. The project was complex and with a timeline to be completed within 4 days of arrival, however the team went to work and successfully completed all port formalities, customs clearance, trucking and delivery to their yard, located close to the Jebel Ali Terminals, on time and within the budget.

Transmaritim handles logistics challenges all over the world

GPLN member Transmaritim International from Germany shipped this month an excavator from Dalian, China to Algeria.

They shipped also a locomotive from Hamburg, Germany to Norfolk, USA. Their work is characterized by personal and good communication at eye level. If necessary, their employees on site, like here in Hamburg, check the freight again and ensure that the customer’s individual needs are met. High, wide and heavy logistical challenges are exactly what they are made for since 1987 for all kinds of services, tailored to the needs of their customers, as an all-round solution for any cargo.

SARR Moves Heavy Engineering Goodsx

GPLN member SARR Freights from India completed recently a delivery of 175 tons of heavy engineering goods from Muzaffarnagar, State of Uttar Pradesh in India, to Germany. The project included road transportation, custom clearance and sea carriage through Mundra port. The extremely severe Cyclonic Storm Biparjoy hit the port at the time of the scheduled sailing of the vessel, posing obstacles and risks to the cargo. The team at SARR were able to use their experience, expertise and network to mobilize solutions to ensure that the cargo was delivered safely in a timely manner for our client. This project marked another successful international undertaking for our company, backed by over 35 years of experience and a dedicated team of experts.