A word from GPLN: Newsletter Issue 96 / January-February 2024

Dear Reader,

Breakbulk Middle East which took place from February 12-13, 2024 in Dubai was a big success for GPLN and 7 GPLN member companies who joined our booth: transmaritim international/Germany, Indial Shipping/India, JSL Global/Qatar & Oman, ITM Projects/Mexico, Expo Freight/India, Splendour Marine/UAE and AZKA Shipping & Logistics/Iraq.

The Middle East is expected to see many new projects coming up during the next few years. Out of these, petrochemicals will have the highest number of projects. The key countries in the Middle East oil and gas projects market are Saudi Arabia, United Arab Emirates, Iraq, Kuwait and Oman, among others.

The world economy in 2024 is expected to outperform previous projections according to Goldman Sachs Research, with worldwide GDP forecasted to expand to 2.6% this year. While some economists are optimistic about global economy recovery, logistics professionals are predicting only a slow growth in the first half of this year.

Despite some hesitation surrounding global growth prospects this year, African investments and commitments look positive, due to the UK, who plans to invest USD 2 bn in sustainable projects across Africa, and the USA who has pledged an initial USD 200 bn for the Partnership for Global Infrastructure Initiative (PGII).

Furthermore, considering that Asia accounts for more than 60 percent of global growth, the expanding APAC market is anticipated to see sizeable investments in power generation. Analysis from Wood Mackenzie forecast investment totalling USD3.3 tn over the next decade focused on that sector, with 49 percent for wind and solar and 12 percent for energy storage.

Up to now around 120 GPLN members have already registered for our 19th annual global conference which will take place at the Hilton Hotel in Den Haag from May 18-20, 2024. We are looking forward to another successful meeting after our last year’s record attendance.

Our Heavy Transport and Lifting Seminar is scheduled just after our meeting on May 21, 2024 at the same venue, which is also open for non-members and has still a few seats left. All relevant details about these events are published on our dedicated pages of our website.

Furthermore, both GPLN events can be combined with Breakbulk Europe which is scheduled right after our events at Ahoy Convention Center in Rotterdam.

GPLN will exhibit at this event and has secured a prime location in the main hall with a 36 sqm booth (# 1A20) which is the equivalent to 4 regular stands. We still have spots available for GPLN members to share our stand which will be another great opportunity for networking with around 10’000 visitors. Please contact our GPLN team for more information.

Best regards,

Your GPLN team

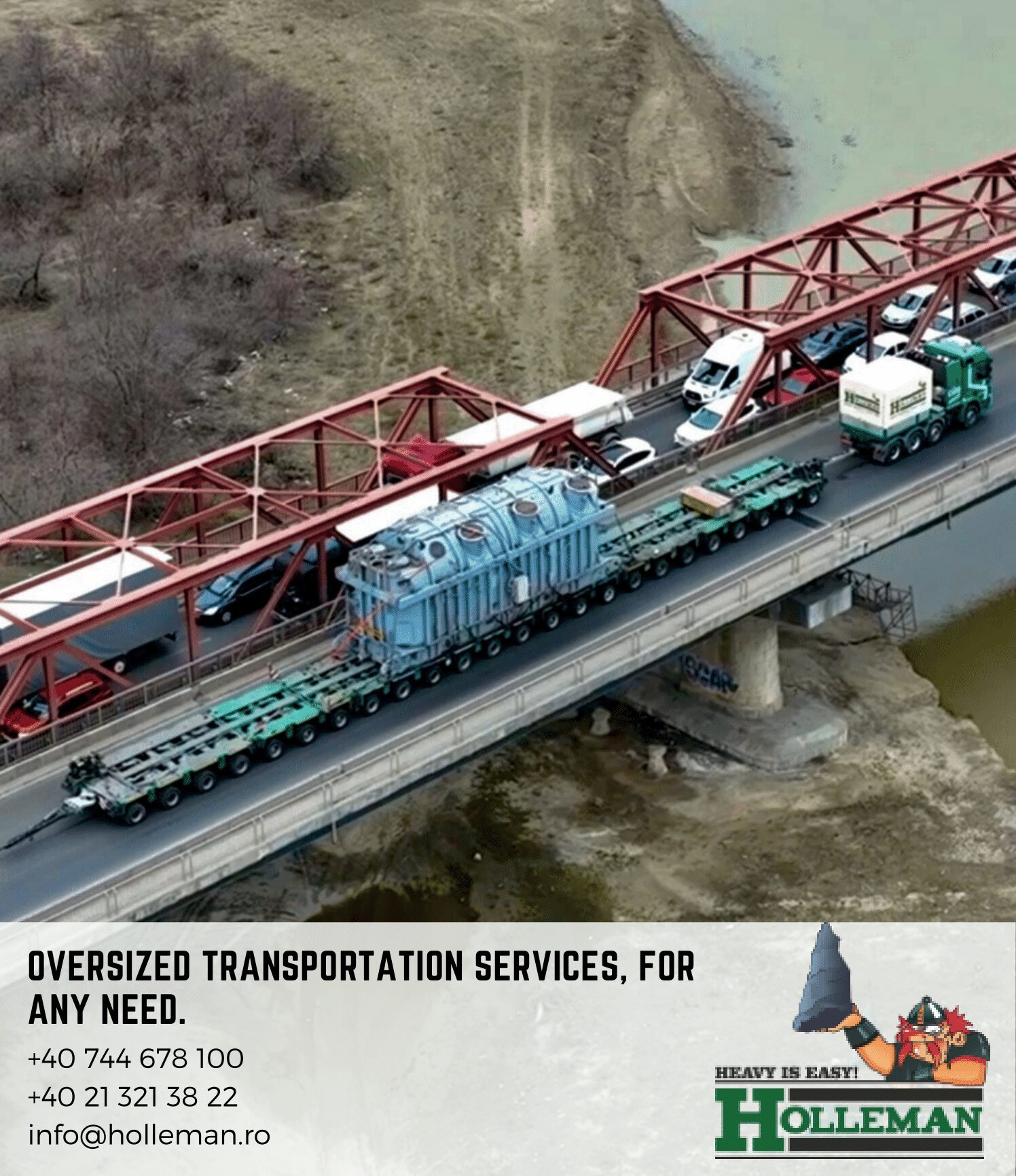

Holleman handle a Transport Mission with a Humanitarian Perspective

The team of GPLN member Holleman from Romania is thrilled to share the story of a transport mission that not only highlighted remarkable speed and efficiency but also carried a significant humanitarian aspect.

This exceptional journey involved the transportation of one of two transformers bound for Ukraine and was executed with precision and dedication. The transformers, one weighing over 200 tons, were transported using a specially designed trailer and a team of highly skilled professionals. The team worked meticulously to ensure that the transformer was transported safely and efficiently to its destination. What distinguishes this mission is the remarkable timeline: just four days. From the bustling Port of Constanta on the shores of the Black Sea to the heart of Ukraine, Chernivtsi, the entire operation unfolded in record time.

While the mission’s efficiency underscores Holleman’s logistics and technical capabilities, it also reflects the company’s steadfast commitment to humanitarian causes. In a world marked by conflict and uncertainty, the Holleman team demonstrated not only their proficiency but also their deep sense of responsibility. By venturing resolutely into a country embroiled in turmoil, they took calculated risks to extend assistance and support to Ukrainian communities.

Holleman is overcoming challenges to deliver Wind Turbines

GPLN memeber Holleman from Romania successfully transported some of the largest wind turbines ever installed in Romania to Pechea, Galați County, marking a significant milestone in Romanian’s transportation landscape. This accomplishment reflects Holleman’s expertise and dedication to advancing clean energy solutions.

The dedicated team at Holleman faced substantial challenges in bringing this project to fruition. The triumph of this endeavor underscores Holleman’s skills, determination, and passion for overcoming obstacles.

The journey commenced at the Port of Constanța, where Holleman orchestrated the transfer of the wind turbines to the new wind farm in Galați County: blades stretching an impressive 80 meters, tower sections reaching up to 33 meters, diameters of up to 5 meters, and weights of up to 90 tons. And to that, a 95-ton generator and a 75-ton gearbox – all critical components for the wind turbines.

Unloading these elements from ships and carefully loading them onto trailers for the onward journey required precision and collaboration. Holleman is especially grateful for the seamless partnership with the port operator SCS, whose professional team played a vital role in the success of this venture.

Holleman’s approach, from ship arrival to unloading at the wind farm site, underscores the company’s unwavering commitment to quality and integrity. The colossal blades, towering towers, and heavy-duty components are set to generate clean energy, making a significant difference in powering homes and promoting sustainability.

|

New GPLN Members Issue 96 / January – February 2024 |

||

| Colombo | Sri Lanka | Projects FPS (Pvt) Ltd |

| Ecuador | Quito | Garinmopoint Cia Ltda |

| India | Mumbai | Auxin Shipping Pvt Ltd |

| Saudi Arabia | Jeddah | Ark Alliance Logistics SPC |

Protranser are busy with various overseas shipments

GPLN member Protranser’s team from China delivered recently 2 sets of 54.8 tons transformers from Shanghai, China, to South Asia. The dimension of the main body was 5,00*3,15*3,35 m. Working scope was chartering service of breakbulk vessel.

They delivered also14 sets of transformers from Wuhan, China to Romania by 3 lots via 3 different ports of loading (POL). 7 sets of them were exported from Shanghai port (105 PKGS / 315385 KGS /658.89 CBM), 5 sets of them were exported from Zhangjiagang port (77 PKGS / 251075 KGS / 506.93 CBM) and 2 sets of them exported from Tianjin port (34 PKGS /120180 KGS / 231.14 CBM).

The weight of the main body ranged from 27.7 tons to 54.7 tons. Working scope included picking up cargo from the factory in Wuhan, delivering to POL and port services and customs clearance services.

© Protranser International Logistics Co., Ltd. All rights reserved

Furthermore, Protranser delivered 13000cbm steel structure from Shanghai, China to Oran, Algeria. They supervised the whole operation process of collecting cargo and loading at POL and discharging at POD, greatly reducing cargo damage. Working scope was chartering a breakbulk vessel. All cargo was shipped safely and to the full satisfaction of the client.

Their team delivered also 453 CBM cargo from Zhangjiagang, China to Eastern Europe. The cargo was consisting of two sets of Die Casting Machine and the total volume was 40 PKGS / 241TONS / 453CBM. Working scope was chartering service of the breakbulk vessel.

Finally, Protranser delivered 15 pieces of Hydrogen storage cylinders from Taicang, China to Gladstone, Australia. The weight and dimension of each one was 35 tons and 12.06*2.34*1.72m (L*W*H). The total volume was 730 CBM. Working scope included shrink film service at factory, picking up cargo from factory and delivering to Taicang port and port service. The consignee of the project was one of the top 3 mining corporations in the world.

MOHAB handle Surface Drilling Machine

GPLN member MOHAB’s Christmas gift was loaded towards of last year in Finland at Helsinki Port for its final destination to Tunis Port.

This over dimensional cargo was our special gift to end the 2023 year that started with recession activities in freight forwarding business in Tunisia. Dimension of this Surface Drilling Machine was 0.7 m (L) x 2.5 m W) x 3.6 m (H) and the weight 15,200 kg.

Our team has worked hard in the past to keep up the good spirit and we have started new adventures, and we look forward to a better 2024 with new objectives.

Consolcargo move Industrial Generator

GPLN member Consolcargo from Colombia is pleased to share the successful movement, both terrestrial and maritime, of a industrial generator and its accompanying parts as per export requirements. The entire process, carried out in 2023, was meticulously executed within established parameters and met the expectations outlined by your team.

The ground phase involved the seamless transportation of the generator and parts from our facility to the designated port of embarkation. This leg of the journey was managed efficiently, ensuring the safety and integrity of the cargo throughout.

Upon arrival at the port, the transition to maritime transport was executed with precision. The cargo was securely loaded onto the vessel, taking into account all necessary precautions to guarantee its protection against any potential risks during the sea voyage.

With 21 years of experience in the field, Consolcargo’ s team consists of seasoned professionals who excel in the intricate handling of project cargo and oversized shipments. We pride ourselves on being at the forefront of industry knowledge and innovation.

Nabros delivers largest Reactor at longest distance

GPLN member Nabros Transport Pvt. Ltd. From India created a history by moving a super ODW HDT Reactor of 971 MT for the first time in the country, overcoming many challenges and with military-like planning & precision. Nabros team achieved a feat by delivering this colossal super ODW Reactor from Mundra Port to HMEL, Bhatinda Refinery travelling 1400 km across 4 States. The movement started on 7th January’2023 and it was delivered on 5th December’2023.

However, the project had started on the drawing board long before its physical movement and structural strength-weakness analysis across the route was diligently done through detailed recce for more than 6 months. This meticulous survey helped Nabros experts to identify the bottlenecks and critical challenges.

This mammoth task was achieved by overcoming multiple challenges like crossing rivers & canals by constructing 34 special bypasses, crossing 174 normal bridges and 2 specially created bridges, passing through narrow & congested cities & villages, removing & restoration of more than 6000 KV power lines and 40 Nos. Of 220 KV, 132 KV & 66 KV Lines, crossing 14 busy Railway Crossings / ROB through traffic & power blocks, recreating bypasses washed out by rain, removal & restoration of 45 overhead signs etc.

Speaking on this occasion, Mr. Tapan Patel, Director, Nabros Transport said “Nabros Transport is one of the most experienced ODC Logistics Company with 41 years of experience. Challenges like narrow and congested roads, and rivers, removing and restoring civil infrastructure, Power lines, crossing Railway line and ROBs etc. make us more determined every time, and accepting such challenges and overcoming them is second nature for us. This project required our team to patiently execute and achieve each & every project milestone and I am proud that Nabros Team did it safely & successfully.”

Enthralled by Nabros team’s momentous achievement, Mr. Jignesh Patel, Director, Nabros Transport said,” Our scientific project management approach with the best-in-class infrastructure, technical know-how and teamwork helped us to achieve this colossal task. This is not just a matter of pride for us at Nabros Transport as industry leaders, but this is also a moment to celebrate for the entire ODC Cargo and shipping industry. This new benchmark also reflects the infrastructure growth propelled by our progressive government policies. We also acknowledge and express our gratitude for the staunch support provided by our client L&T HED.”

Nabros staunchly believes that challenges are the stepping stones to reach new echelons of success, and every stepping stone is a new milestone to climb new summits of growth. Nabros is resolute in its pursuit of excellence in every new endeavour in times to come.

Eastship handle Power Plant

As part of the Iernut project in 2024, GPLN member Eastship from Romania transported seven autoclaves over a distance exceeding 700 kilometers. Each autoclave measured 24 meters in length, 3.3 meters in height, 3 meters in width, and weighed 45 tons.

For the internal movement at beneficiary’s premises, we have used a tailor-made system engineered, built and operated by our crew. We designed and constructed robust trolleys, each capable of supporting 45 tons, and mounted them on rails. The autoclaves were carefully placed onto these tailor-made trolleys, and a specialized pulling system was employed to transport them to their final locations. Utilizing a jacking and skidding system, we systematically removed the trolleys and rails, lowering the autoclaves to their designated final destination.

FOX Brasil hande game-changing project in sustainability and local development

Suzano’s Cerrado Project, in numbers, is considered the largest Pulp and Paper manufacturing unit in the world under construction, the best eco-efficiency index in its manufacturing process with very low carbon emission rates and minimal use of fossil fuels.

GPLN member FOX Brasil Project Logistics Team was honored to be tasked with moving Manipulators that would be used in the Project from the Port of Santos to the construction site in Mato Grosso do Sul, Brazil.

That meant over 1100 kilometers by land freight, carrying no less than 1192,298 tons of machinery shared between 157 pieces which were divided into 68 land shipments!

But let’s start from the beginning: The first step to make this project come to life was a detailed inspection, which allowed the team to account for every particular piece and arrange adequate vehicles and complimentary equipment to properly transport each of them.

With that, the team was able to meticulously plan the load, organizing, sequencing, and routing for an efficient workflow. The transport from the port to the job site was monitored closely and daily and, upon its arrival, the team observed item positioning, aligning the unloading assigned place with each machine assembly sequence.

As the operation concluded, all the data gathered was compiled in a report, categorizing insights by equipment and machine types, a very valuable record that can be extremely useful in future logistical endeavors!

Zenith move Oil processing equipment

GPLN member Zenith International Freight from UK successfully supported their client in moving Oil processing equipment from the Factory in China to delivered door UK.

The move comprised of 6 units totalling 120,940 kg / 774 m3

Due to the lack of breakbulk vessel availability for direct shipment from China to the UK, the best route available was to move the cargo from Zhangjiagang to Antwerp and then from Antwerp to the UK via Barge into Tilbury.

Once in Tilbury the next challenge was moving the loads to their final delivery location in Kent. This required the goods to be moved across the Thames River via the busiest bridge crossing in the UK and transporting this OOG equipment over the bridge would involve having the crossing closed to general traffic for the duration of the move.

For several weeks Zenith worked together with the British Transport authorities and the Police to arrange movement permits for private escorts vehicles, polices escort vehicles that the physical closure of the Dartford crossing to general traffic for an allotted period of time.

Due to the size of the cargo, the authorities would only allow transportation of 2 units in any one movement, so Zenith eventually agreed with the authorities to have the bridge closed to general traffic for 2 hours from midnight until 2am on three consecutive nights (Friday, Saturday, Sunday) to allow the cargo to cross.

The operation went perfectly and the client was extremely pleased to receive all 6 of their units waiting for them on site on the Monday morning.

CKB Logistics complete State Point Liquid Cooling Project

GPLN member PT Cipta Krida Bahari (CKB Logistics) from Indonesia has recently completed the logistics project of Heavy Lifting, Transport and Skidding of this State Point Liquid Cooling (SPLC) set, owned by PT Ekagrata Data Gemilang (EDGE).

The Heavy Lifting, Transport and Skidding of this SPLC logistics project is the first SPLC project in Indonesia. With a total main cargo weight of 30 tons after assembly, the entire cargo was lifted using an 800-ton crawler crane at a building height of 105 meters.

The SPLC set was mobilized from CKB Logistics – Jakarta Mega Hub Cakung to the EDGE 2 DC Project building site in Kuningan, South Jakarta. The dismantled 800-ton Crawler Crane was mobilized for assembly and erection at the EDGE 2 Data Center site. In addition to the weight of the cargo that was too large to be lifted on a building with a height of 105 meters, other obstacles were the work location in the middle of the city and the relatively narrow crane area due to the river / riverbank.

A prudent survey, operating plan analysis, routes, timeliness of operation and type of transportation were key factors for a successful delivery, which are part of CKB Logistics solution to meet customer expectations. With CKB Logistics extensive experience of over 2 decades in handling a wide range of logistics projects, the Heavy Lifting, Transport and Skidding of SPLC (State Point Liquid Cooling) EDGE 2 Data Center was completed safely and smoothly.

ITM Projects transport heavy and large cargo

GPLN member ITM Projects from Mexico performed recently an outstanding service by delivering 4 Press Machines, each of them 168 tons in weight, as well as 25 truckloads of accessories from Altamira Port to San Luis Potosi in Mexico.

Furthermore, they moved also Oil Refinery equipment which was 4.95 meters in height and had a weight of 85 tons, going from Altamira Port to the Pemex Refinery in Tula, a town in the municipality of Hidalgo in central-eastern Mexico

With continuous investment in new heavy haul equipment, ITM are ready to help with any Mexico projects.

IBC support humanitarian aid organization in Honduras

An Austrian customer of GPLN members IBC Internationale Spedition decided to go to Honduras with his wife and kids to work for a humanitarian aid organization called “Cracias a Dios”

Considering that a used Rosenbauer Unimog, formerly used by a fire brigade in Upper Austria, was urgently needed to supply people outside the big cities with fresh water, food, medicine, clothes etc. our task was to bring the Unimog from our warehouse in Linz into the deep jungle of Honduras.

Based on the know-how of IBC, this logistical demanding transport of the Unimog could be carried out without any problems and the Unimog already is doing a great job in the jungle. For IBC no distance is too far and no transport is impossible!

Transmaritim international transport high and heavy cargo

GPLN member transmaritim international from Germany is specialized in the transport of high and heavy cargo. An area where precision and expertise are essential. From oversized vehicles to massive machinery, they offer tailor-made solutions for the safe transportation, as shown with the picture of a recent shipment. The commodity was machines for packaging with a weight of 120 tons and the dimension 6 x 2.50 x 3.25 m each. The 3 machines were shipped by Ro-Ro from Hamburg in Germany to Xingang in China.

Prism Logistics is overcoming Logistic Challenges

Vijay Tanks & Vessels Pvt Ltd secured a significant contract for the supply of two Coke Chambers for the Indian Oil Corporation Limited (IOCL) Baurani Project. The project involved intricate logistical challenges due to the massive dimensions of the cargo and the vast geographical span from the loading point to the final destination.

Project Overview:

Loading Point: VTV Kandla SEZ

Destination: IOCL Barauni, Bihar

Cargo Dimension: Coke Chambers L-36.274m x W-9.10m x H-9.4m | WT- 390 MT (Each)

Scope of Work:

a) Inland transportation VTV Kandla Sez to Kandla Port:

Navigating through the local terrain, the team ensured the safe and efficient transportation of the Coke Chambers from the manufacturing site to Kandla Port.

b) Sea movement from Kandla Port to Diamond Harbour:

Coordination with shipping agencies and adherence to maritime regulations were crucial for the smooth sea movement. The team optimized routes and schedules to minimize transit time.

c) Transhipment at Diamond Harbour:

At Diamond Harbour, a critical transhipment process was executed seamlessly to transfer the cargo from the initial sea vessel to a more suitable barge for further inland transportation.

d) Barge movement from Diamond Harbour to Simariya Jetty:

Navigating inland waterways, the barge movement was executed with precision, taking into account tidal conditions and other environmental factors.

e) Permissions & charges for Road / Sea movement up to IOCL:

A comprehensive approach was taken to secure all necessary permissions for road and sea movements, ensuring compliance with regulations and minimizing delays.

f) Inland transportation from Simariya Jetty to IOCL, Barauni site:

The final leg of the journey involved transporting the Coke Chambers from the jetty to the IOCL Barauni site, overcoming challenges posed by local infrastructure and ensuring safety.

Outcome:

Despite the complex logistics involved, Vijay Tanks & Vessels Pvt Ltd successfully delivered the Coke Chambers to IOCL Barauni, Bihar, meeting all project deadlines and ensuring the integrity of the cargo throughout the transportation process.

Key Success Factors:

Meticulous planning and coordination at each stage of the transportation process.

Proactive management of regulatory compliance and obtaining necessary permissions.

Effective communication and collaboration with shipping agencies, transhipment facilities, and local authorities.

Adaptable strategies to overcome unexpected challenges during transportation.

Conclusion:

The successful execution of this project showcases Vijay Tanks & Vessels Pvt Ltd’s capability to handle complex logistics associated with oversized cargo, reaffirming their commitment to delivering high-quality solutions to their clients in the oil and gas sector.

Conclusion:

The successful execution of this project showcases Vijay Tanks & Vessels Pvt Ltd’s capability to handle complex logistics associated with oversized cargo, reaffirming their commitment to delivering high-quality solutions to their clients in the oil and gas sector.

Also, Successful Execution of Complex Logistics for Thyssenkrupp Industrial Solutions in NRL Project Thyssenkrupp Industrial Solutions embarked on a crucial project for the NRL (Numaligarh Refinery Limited), involving the transportation of critical equipment from the manufacturing site at VTV Kandla Works to Diamond Harbour. The project presented unique challenges, including road transportation, civil works, and sea freight, requiring meticulous planning and coordination.

Cargo Dimensions:

Vacuum Column Assy: 48.154m (L) x 11.168m (W) x 11.329m (H) | Weight: 724 MT

Crude Column Assy: 60.9m (L) x 6.893m (W) x 7.186m (H) | Weight: 413 MT

Crude Column Skirt: 8.17m (L) x 8.17m (W) x 7.408m (H) | Weight: 76 MT

Scope of Work:

a) Road Transportation from VTV Kandla to Kandla Port:

Ensured the safe and efficient transportation of oversized equipment from the manufacturing site to Kandla Port, overcoming challenges posed by the dimensions of the cargo.

b) Civil work and all permissions en route:

Undertook comprehensive civil works, including modifications to infrastructure en route, to facilitate the smooth passage of the cargo. Obtained all necessary permissions and clearances to ensure regulatory compliance.

c) Sea Freight from Kandla Port to Diamond Harbour:

Coordinated the sea freight operation from Kandla Port to Diamond Harbour, optimizing routes and schedules to meet project timelines.

Outcome:

Thyssenkrupp Industrial Solutions (India) Pvt Ltd successfully executed the NRL Project, demonstrating their expertise in managing complex logistics associated with oversized and heavy cargo. The timely delivery of the equipment to Diamond Harbour underscored their commitment to project deadlines and client satisfaction.

Key Success Factors:

Proactive planning and coordination to address challenges associated with road transportation of large equipment.

Comprehensive civil works and permissions management to ensure a seamless journey en route. Efficient sea freight operation, optimizing routes for the safe and timely delivery of cargo.

Conclusion:

The successful completion of the NRL Project solidifies Thyssenkrupp Industrial Solutions’ reputation as a reliable partner in executing intricate projects within the industrial sector. Their commitment to quality, safety, and adherence to project timelines positions them as a leader in providing end-to-end solutions for complex logistical challenges.

KCTC load out FPSO components

KCTC Transportation company from Korea sourced Cometto self-propelled modular trailers (SPMT’s) to load out FPSO components with a combined weight of 63,781 tons in South Korea.

Samkang S&C outsourced the load-out project to KCTC, which mobilized Cometto’s MSPE EVO2 vehicles from Global, Daemyung and Anjeon. Six modules were transported into position, with 288 to 360 axle lines utilized per move.

The FPSO is being built for the Barossa project – a gas and condensate field in the Bonaparte Basin of the Timor Sea, offshore Australia – in which Singapore’s BW Offshore participates as a developer. The FPSO itself, when complete, will have a main deck length of 340 m, a width of 64 m, and a height of 31.5 m.