A word from GPLN: Newsletter Issue 97 / March-April 2024

Dear Reader,

As you know we are celebrating this year our 20 Years Anniversary and are pleased to announce that we have now reached over 180 GPLN attendees for our AGM which is scheduled from May 18-20, 2024 at the Hilton Hotel in Den Haag.

Our renown Heavy Transport and Lifting Seminar is also well booked and scheduled just after our meeting on May 21, 2024 at the same venue. This technical course is open for both members and non-members and has still a few seats left. More details are published on our dedicated pages of our website.

Both GPLN events can be combined with Breakbulk Europe which is scheduled from May 21-23, 2024 at Ahoy Convention Center in Rotterdam.

GPLN will exhibit at this event and has secured a prime location in the main hall with a 36 sqm booth which is the equivalent to 4 regular stands. Several GPLN member companies will share our booth, namely (in descending order): Wirtz Link Service/China, Terminal Logistics Services/Kazakhstan, SPLENDOUR MARINE/UAE, Nabros Transport/India, JSL Global Qatar & Oman & Saudi Arabia, ITM Projects/Mexico, Herfurth Logistics/Belgium & Turkey and BCUBE Connect/Italy. Please visit us at our GPLN booth # 1A20 in Hall 1.

Furthermore, we would also like to take this opportunity to thank our AGM sponsors for their great support.

We are looking forward to meeting soon a multitude of GPLN members and visitors in The Netherlands!

Best regards,

Your GPLN team

Fleet Line Shipping takes flight amidst Red Sea crises!

Amidst the Red Sea crises, UAE/Dubai-based GPLN member Fleet Line Shipping (FLS) successfully orchestrated the seamless transportation of an 80-ton rotor via a chartered Antonov-124 flight to Germany. This critical component, essential for our clients’ operations, was on an urgent mission for repair.

FLS’s dedicated team ensured a swift and secure transfer, overcoming logistical hurdles with precision. The rotor will undergo crucial repairs, and after a few weeks, it will soar back to Dubai, ready to power industry and innovation again!

Furthermore, FLS successfully loaded out eight RTGs gantry cranes on Ro-Ro method from Jebel Ali measuring 15.5m x 26.2m x 35.5m with and a weight of 219 tons each.

And finally, Fleet Line Shipping won Hapag Lloyed’s top customer award for seven years in a row. They recently also won a top customer award from CMA for their performance in 2023.

|

New GPLN Members Issue 97 / March – April 2024 |

||

| Azerbaijan | Baku | C. Steinweg Caspian |

| China | Shenzhen | Headseaway International Logistics Co., Ltd. |

| Costa Rica | San Jose | Tripp Cargo Logistics S.A. |

| Finland | Rauma | Pfaff International GmbH |

| India | Chennai | Go Gauge Logistics Private Limited |

| India | New Delhi | Dacotrans India Pvt. Ltd. |

| Saudi Arabia | Dammam | JSL Global (Al Jassim Freight) |

| UAE | Dubai | Navigators Shipping And Logistica L.L.C. |

| USA | Chicago | Juno Logistics, Inc |

| Vietnam | Ho Chi Minh City | Dextrans Worldwide Vietnam Co., Ltd. |

SCT LOGISTICS deliver heavy gantry crane

GPLN member SCT Logs from Vietnam delivered recently successfully a gantry crane from Phom Phen Autonomous port in Cambodia by barging from Vietnam to Cambodia. They arranged also lashing, securing and dunnage on the barge.

Furthermore, beforehand a method statement was arranged after discussions with the barge owner and sub-contractor to do lashing/securing/dunnage on barge in order ensure a smooth handling without any arising charges.

Commodity: Dissembled gantry crane / Volume: 44 packages/ 140 tons/ 600 CBM

There were many OOG packages with following dimension/ weight:

13.856mLx 4.641mWx1.9mH/ 16 tons & 13.150mLx 5.121mWx1.9mH/ 17 tons & 11.650mLx2.9mWx 3.8mH/ 34 tons

M.G. International Logistics move heavy equipment

GPLN member M.G. International Logistics from Germany moved oil field equipment for a project from UAE via the Southern port city of Umm Qasr to the final destination in Missan, Southeastern Iraq.

Weight of the unit: 44,75 ton / Dimension: 31,00 x 3,35 x 4,36 m

Way of transportation: ex-factory UAE to Jebel Ali Port by multi-axle hydraulic trailer and from Jebel Ali to Umm Qasr by conventional breakbulk vessel (part-charter) and from Umm Qasr to Missan by multi-axle hydraulic trailer.

This transportation was part of a total phase of a project with an overall volume >20,000 freight tons.

Bruhat Logistics move Break Bulk Cargo

GPLN member BRUHAT LOGISTICS from Singapore has recently moved a breakbulk shipment of crawler cranes from Hong Kong port to South Korea port. The cargo was disassembled and transported on a breakbulk vessel.

After conducting a cargo survey, the items were received in the barge and subsequently loaded onto the breakbulk vessel. Along with the main units, 121 multiple units were also received and shipped. The total weight was 1479.5 MT.

JSL meet logistic challenge to move Telescopic Suction Pipe

GPLN member JSL Global WLL (Qatar) transported a Telescopic Suction Pipe (Assembled) from Bahrain to Doha via Saudi by road freight for one of the leading alumina refinery companies in Doha based in the industrial city in Mesaieed, located 36 kilometers south of the Qatari capital Doha.

The transportation of the Telescopic Suction Pipe (Assembled) presented a unique logistical challenge, requiring meticulous planning and coordination. With dimensions of L (21M) X W (2.05M) X H (2.4M) and a weight of 10,614 KG, the cargo posed challenges due to its size and weight, necessitating special equipment and careful handling. The project involved transporting the material from Bahrain to Doha, Qatar, via Saudi Arabia, by road freight. This was undertaken for a prominent alumina refinery company in Doha, located in one of the industrial cities in Qatar. The cargo was vital for their plant operations, demanding adherence to strict timelines.

Specialized trailers, including a Long Trailer of 22 meters for cross-country shipment, were utilized, followed by a 22-meter-long trailer for in-country movement to the client’s site. Challenges arose during the transportation process, notably obtaining permits for the Bahrain Causeway and undergoing X-ray scanning at the KSA border due to the cargo’s length. To meet the client’s time-sensitive requirements, thorough planning was essential. Gate passes, escort approvals, and cross-loading plans were arranged precisely to ensure seamless movement and adherence to deadlines.

Despite the logistical hurdles, collaborative efforts and strategic planning ensured the successful delivery of the Telescopic Suction Pipe, demonstrating our commitment to meeting client needs under challenging circumstances.

Polaris International Projects’ Initiatives in 2024

GPLN member Polaris International Projects, the project logistics division of Polaris Shipping Agency LLC based in Dubai, United Arab Emirates, is thrilled to share exciting updates. As we kick off 2024, we express our heartfelt gratitude to our loyal customers and associates for their unwavering trust and support.

Urgent Rotor Transport Frame Mobilization:

Our dedicated Polaris Project team swiftly handled the urgent mobilization of a rotor transport frame. The frame, with shipping dimensions of 1455 x 215 x 166 cm (LXWXH) and weighing approximately 16 MT, was returned from Europe. This critical frame is part of a faulty rotor currently in operation at the Dubai Electricity & Water Authority. Recognizing the urgency, we promptly airlifted the shipment and successfully completed customs clearance. The frame was delivered to contractors on-site within the agreed time frame, allowing us to proceed with the rotor repair shipment.

Other Noteworthy Accomplishments:

Construction Equipment Shipment: We efficiently handled around 3000 FRT of construction equipment from China to the UAE for an esteemed auction company.

Seamless Carbon Steel Pipes: Approximately 4500 FRT of seamless carbon steel pipes were imported from Japan to the UAE. These pipes will be shipped to CIS destinations upon completion of necessary pipelining procedures.

All Terrain Grove Cranes: Polaris secured a contract for shipping around 15 units of all-terrain groove cranes, each weighing 70 tons per unit, from Fremantle, Australia & Haiphong, Vietnam to Mumbai, India. Our trial shipment of one unit has already been discharged at Port Mumbai.

Smart Routing: Due to the unavailability of direct service from Fremantle to Mumbai, we expertly routed the shipment via Port Jebel Ali. Polaris ensured timely transit procedures and seamless on-carriage to Mumbai from Port Jebel Ali.

CONTI-TRANS export Big Burners

GPLN member CONTI-TRANS from Germany handled recently two units of really Big “Burner I + II” per road, barge, terminal and sea freight ex the middle of no-where in Germany for an export overseas to the Fareast.

Dimension and weight of each burner: 2.200 x 5.80 x 6.00m = 766 CBM and 177 tons per piece.

Furthermore, Conti-Trans Germany is proud to announce and present you an improved set up since 2023. We implemented and defined an individual „International Business Affairs “department under the umbrella of our „Management Board”.

Your assigned contact persons for all of your project OOG inquiries – either Sea, Air or Road – are centralized under the well-known “International Business Affairs Managers”: Mr Simon Jaques and Mr Andreas Tini, besides Ismet Sari.

Conti-Trans is a neutral and trustable, long term thinking forwarding company, existing since 1973 with its headquarter in Cologne and a proud member of GPLN since 2011.

Egyptian Global Logistics move Transformers

GPLN member Egyptian Global Logistics (EGL) moved recently 3 units of transformers (135 tons each), 1,750 CBM accessories and oil tanks from vessel to the job site of the Suez Canal Economic Zone (SCZONE).

Short Introductions: The Suez Canal Economic Zone (SCZONE) holds significant importance due to its strategic location on the Suez Canal, a crucial link for global trade. This prime position allows SCZONE to function as a major logistics hub, attracting businesses and investments. Additionally, the zone offers various incentives and streamlined processes, making it an attractive destination for companies seeking to establish themselves in the region. Overall, SCZONE plays a vital role in driving economic growth and development in Egypt

Project name: Eqtesadiya-Substation (SCZONE)

Client name: XD-EGEMAC

Cargo type:

3 units Transformer’s (135 ton/each)

General Cargo (Accessories) 1,750 CBM

Scope of work:

EGL made route and site survey before executions

Receive Transformers from Vessel (under Hook).

Offloading and Re-Loading Transformers by using Hydraulic Jacks, beams and supports.

In-Land Transportations to job site including accessories and oil tank’s.

Managed to get all necessary road permits from utilities

Jacking and skidding transformers to foundations

List of Equipment’s used:

Three Hydraulic Modular (TTL 36 axles).

Jacking & Skidding Enerpac system (Hydraulic & Pushing Jacks, steel & support beams, Rollers & wooden blocks)

Supply Forklift and Crane for offloading Jacking and Skidding tools.

Challenges: –

Tight executions schedules from date of release transformers from port till offloading to foundations.

Site entrance very narrow for heavy transformers.

Long skidding distance almost 18-meter length to center positions.

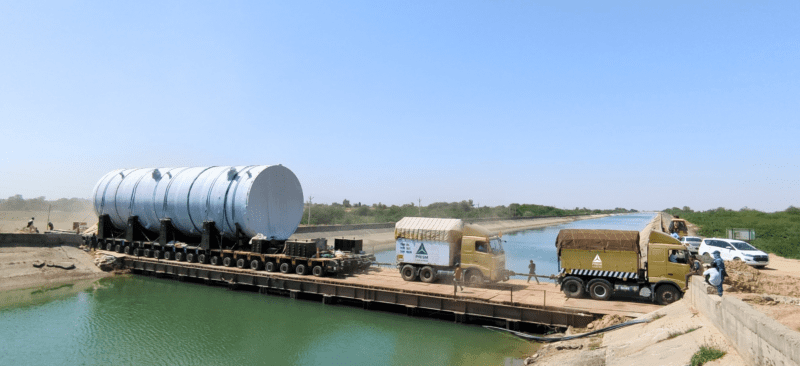

Prism Logistics handle Reactor Modules in the IOCL Panipat Project

GPLN member Prism Logistics Pvt. Ltd., from India, a company renowned for its proficiency in logistics management, recently undertook a critical project for IOCL’s esteemed Panipat Refinery. The project centred on the transportation and installation of VGO (Vacuum Gas Oil) Reactor modules, an endeavour demanding precision and flawless execution. With an unwavering commitment to quality and efficiency, Prism Logistics embarked on this venture, fully prepared to meet and exceed the expectations set forth by IOCL.

Indian Oil Corporation Limited (IOCL), a pioneering force in the Indian Oil and Natural Gas sector, has cemented its status as a household name, striving relentlessly to ensure the availability of petroleum products in every corner of the nation. As a Fortune 500 company, IOCL continuously seeks avenues for growth, relying on the expertise of various partners to navigate the complex landscape of the industry. In its pursuit of excellence, IOCL relies on competent logistics services and this is where Prism Logistics comes into play.

Project Overview:

The magnitude of the project cannot be overstated, as it involved the intricate orchestration of various logistical and engineering elements. The journey commenced at the manufacturing site located in L&T Hazira, Gujarat, where the VGO Reactor modules were meticulously crafted. These modules, comprising the Top Section, Bottom Section, and Skirt Section, boasted formidable dimensions and weights, presenting formidable challenges to be surmounted.

The Top Section, measuring an impressive 25.435 meters in length, 7.70 meters in width, and 7.20 meters in height, tipped the scales at a staggering 796 metric tons. Meanwhile, the Bottom Section, spanning 25.60 meters in length, 8.00 meters in width, and 7.70 meters in height, weighed an imposing 756 metric tons. The Skirt Section, standing at 9.575 meters in length, 8.75 meters in width, and 4.10 meters in height, added an additional weight of 108 metric tons to the logistical equation. Thereby amounting to a total of a whopping 1660 metric tons.

The scope of work undertaken by Prism Logistics encompassed a multifaceted approach, involving road transportation, barging, and civil modifications to ensure seamless integration of the reactor modules into the Panipat Refinery infrastructure. Each phase of the project demanded meticulous planning and precise execution to navigate the intricate logistical landscape effectively.

Road Transportation from L&T works to L&T RO-RO: The experts at Prism had to ensure the safe and efficient road transportation of the Over Dimensional Cargo from the manufacturing site in L&T Hazira, Gujarat to the designated L&T Roll-On/Roll-Off (RO-RO) facility.

Barging from L&T RO-RO jetty to Mundra Jetty: The logistics mavens at Prism ensured seamless transfer of the reactor modules onto barges for transportation via waterways to Mundra Jetty.

Road Transportation from Mundra Jetty to IOCL Panipat Site: The Prism officials closely coordinated the road transportation from Mundra Jetty to the IOCL Panipat Refinery, optimizing the routes and addressing all challenges en route.

Civil work for modification, Road modification & canal crossing: The Prism team undertook civil works at the IOCL Panipat site, including modifications for the reactor installation, road enhancements, and canal crossing to ensure smooth transportation.

Challenges Faced:

The endeavour was not without its challenges, as the dimensions and weights of the reactor modules posed significant logistical hurdles. Manoeuvring such colossal cargo demanded precision and expertise, with every aspect of the transportation process meticulously scrutinized to ensure the safety and integrity of the cargo.

The project’s multimodal nature, combining road and barge transportation, added further complexity to the equation. Additionally, civil works were required at the Panipat Refinery site to facilitate the installation of the reactor modules, necessitating careful coordination and execution.

Railway shutdowns posed another significant challenge, as the transportation route traversed multiple railway-level crossings. Coordination with Indian Railways was imperative to secure permissions and facilitate hassle-free movement of the cargo, underscoring the importance of effective stakeholder management.

Furthermore, the sheer weight of the cargo necessitated road fortification along certain sections of the transportation route. Traffic control measures were implemented to ensure the safe passage of the oversized cargo, with Prism Logistics personnel working tirelessly to minimize disruptions and ensure seamless transportation.

The creation of specialized bypasses and temporary 600 metric tons modular steel bridges across the Zazam and Tharad canals further exemplified the ingenuity and resourcefulness of Prism Logistics in overcoming logistical challenges. Removal and demolition of structures along the transportation route were undertaken with meticulous planning, with Prism Logistics liaising closely with relevant authorities to ensure minimal disruption to local infrastructure.

Government permissions were sought with meticulous attention to detail, with Prism Logistics coordinating closely with officials to secure essential approvals for various aspects of the project. The collective efforts of Prism Logistics personnel, comprising over 400 dedicated professionals from diverse fields, were instrumental in overcoming these challenges and ensuring the successful execution of the project.

How the Project Came About:

The success of the project can be attributed to a combination of factors, including careful planning, cost-efficiency, prompt delivery, and the unwavering dedication of Prism Logistics personnel. By meticulously addressing each challenge and leveraging their expertise, Prism Logistics demonstrated their ability to navigate complex logistical landscapes and deliver exceptional results.

Cost efficiency was achieved through meticulous planning and optimization of resources, ensuring that every aspect of the project was executed with maximum efficiency. Prompt delivery was facilitated by Prism Logistics’ commitment to deadlines, with meticulous attention to detail ensuring that project milestones were met in a timely manner.

The project’s success was a testament to Prism Logistics’ ability to conquer challenges and deliver exceptional results, thereby reinforcing its reputation as a trusted logistics partner. By prioritizing customer satisfaction and trust, Prism Logistics has solidified its position as a leader in the industry, earning the admiration and loyalty of clients.

The Success Story:

Despite the formidable challenges posed by the IOCL Panipat Project, Prism Logistics emerged triumphant, setting a new benchmark for excellence in the industry. Through meticulous planning, efficient execution, and unwavering dedication, Prism Logistics demonstrated its ability to overcome challenges and deliver exceptional results.

By adhering to safety standards and regulatory requirements, Prism Logistics ensured the seamless transportation and installation of the VGO Reactor modules, thereby earning accolades for their professionalism and expertise. Continuous communication and collaboration with stakeholders,

including IOCL and L&T, further underscored Prism Logistics’ commitment to delivering quality solutions and fostering enduring partnerships.

Conclusion:

In conclusion, Prism Logistics Pvt. Ltd. has showcased its ability to seamlessly integrate road, barge, and civil work components in the IOCL Panipat Project. The project’s successful execution is a testament to Prism Logistics’ dedication to excellence and their unwavering commitment to delivering quality solutions within the oil and gas industry.

Through meticulous planning, efficient execution, and effective stakeholder management, Prism Logistics has reinforced its reputation as a reliable partner in executing complex projects. As the top echelon of the company’s management ensured the immaculate execution of the project, Prism Logistics has cemented its position as a trusted name in the logistics industry, poised to tackle even the most formidable challenges with confidence and expertise.

Star Shipping handle Full Vessel Services at Port Qasim

During the month of Ramadan, in the middle of March 2024, GPLN member Star Shipping from Pakistan has a set a milestone for its contemporaries in Pakistan, by fully handling Vessel M.V Melody (Bulk Carrier) at Port Qasim for the export shipment of 28,000 metric-ton rice, destined for South Western Africa. Star Shipping was given this challenging task with a squeezed lead-time for handling and loading such an enormous export shipment of 28,000 MT rice (50 Kg bags) at Port Qasim, wherein most of the break bulk vessels take berth and the loading operation therefore remains haphazard due to high-frequency of traffic. Yet, as proven of our long track-record of successful and professional performances and achievements, we performed at our best and handled the whole operation successfully and according to our well-organized management plan.

Phoenix Global Freight Transport Heavy Transformer

The Project team of GPLN member Phoenix Global Freight from Greece recently achieved a remarkable milestone with the seamless transportation of an Out of Gauge and Overweight (OOG & OW) transformer and other OOG parts and crated equipment from Shanghai port to Piraeus port and onwards with six flatbed trailers to Kavala in Northern Greece. The main body was 83 tons with dimensions of 7.15 x 2.49 x 3.65 m, and the total volume: 37 PKGS / 133.080 tons / 271,08 CBM.

The project was executed with precision, utilizing private cranes boasting an impressive 120-ton lifting capacity. Operating at the RO/RO Piraeus terminal, our team orchestrated the meticulous handling of the transformer, employing the assistance of six flatbed trailers. The entire operation adhered to the highest safety standards, with all necessary licenses, permits, and surveys obtained.

Covering a challenging 550-kilometer route, the project culminated in a successful DDP (Delivered Duty Paid) delivery. This achievement not only underscores our commitment to excellence but also garnered admiration from local communities. Video: https://www.youtube.com/watch?v=ckqFjKHcD4E

Juno Logistics Moves Expensive Press Machines

Juno Logistics, Inc., a member of GPLN representing the US, has recently completed the final delivery of press machines utilizing 45 trucks carrying 183 packages weighing 1,077,500 kgs and 1,803 CBM. This project was worth over US $12M, originating from the Port of Savannah and concluding in Somerset and spanned from April 3rd to April 29th, showcasing Juno Logistics’ capability to manage and execute large-scale logistics operations under challenging conditions.

The project faced significant logistical challenges, primarily due to an unexpected reduction in loading appointments at the Port of Savannah. This complication arose from a bridge collapse in Baltimore, which redirected a higher volume of breakbulk cargo to Savannah. Concurrently, the port was transitioning some of its breakbulk operations to the Port of Brunswick, further reducing the availability of loading days from five to only Tuesdays and Thursdays.

Despite these obstacles, Juno Logistics’ Project Cargo Team demonstrated exceptional adaptability and foresight. The team engaged in proactive communication with port authorities to secure necessary loading appointments ahead of time, ensuring that the project stayed on schedule. The diverse fleet of specialized trailers used in this project included a 19-axle trailer, two 16-axle trailers, a 13-axle trailer, a 10-axle trailer, and an 8-axle trailer, each essential for the safe and efficient transport of high-value cargo.

By overcoming these hurdles, Juno Logistics not only ensured the timely delivery of the press machines but also affirmed their commitment to providing reliable, professional services. Each step of the process was managed with the utmost care and precision, reflecting Juno’s dedication to upholding the standards expected by GPLN members.

This successful project showcases Juno Logistics’ expertise in handling complex logistics challenges and reinforces their position as a leader in the project cargo sector. It is a testament to their ability to navigate through unexpected challenges with strategic planning and effective communication, ensuring client satisfaction and project success in demanding scenarios.

CKB Logistics complete State Point Liquid Cooling Project

GPLN member PT Cipta Krida Bahari (CKB Logistics) from Indonesia has completed the logistics project of mobilizing HD/OHT & Big Digger units owned by PT Trakindo Utama and PT United Tractors from Tanjung Priok, Jakarta to PT Antareja Mahada Makmur (AMM) – PT MIFA Bersaudara Jobsite in Meulaboh, West Aceh – Indonesia.

Mobilization of HD/OHT units started from CKB Logistics – Jakarta Mega Hub to Tanjung Priok port, Jakarta and sailed via Landing Craft Transport (LCT) to Meulaboh, West Aceh. Meanwhile, the Big Digger dismantle unit was mobilized to PT AMM – MIFA Jobsite with a total distance of 2,500 KM. Passing through the city of Meulaboh, the mobilization of units can run safely and smoothly despite obstacles and extreme terrain conditions. At the PT AMM – MIFA Jobsite, the Big Digger unit was reassembled using a crane and commissioned before it could be operated.

A prudent survey, operating plan analysis, routes, timeliness of operation and type of transportation are key factors for successful delivery, which are part of CKB Logistics solution to meet customer expectations. With the CKB Logistics extensive experience of more than 2 decades in handling various logistics projects, the mobilization of Heavy Equipment units was completed safely and smoothly.

Sea Cargo Logistics arrange Part Charter for Transformers

GPLN member Sea Cargo Logistics team from Mexico faced a logistical challenge involving the transportation of 5 big transformers and accessories accounting 550 tons of cargo, distributed in 77 packages, with a total volume of 1,100 CBM. Five of these packages stand out due to their high commercial value and dimensions.

Two of the largest transformers measured 8.31m x 4.22m x 4.68m with a weigh of 133 tons each another unit 5.90m x 5.26m x 4.53m and weight of 122 tons and 2 smaller units each 5.50m x 3.60m x 4.20m and weight of 35 tons.

The origin of the merchandise was the port of Mumbai, India, and the delivery of the cargo was made from the port of Altamira to the client’s site located in the interior of the Mexican Republic in San Luis Potosi, with an approx. 550 kms trip to the destination. We used specialized transportation equipment (modular units) to complete the journey without any issues.

Our scope on this operation also included the sea freight transport for which we arranged a part charter service with assistance of our chartering division located in Panama.

One of the main challenges we faced was the Panama Canal transit restrictions. Cargo ship transiting through the Panama Canal locks. Drought, driven by a combination of El Niño and climate change, has disrupted shipping through the Panama Canal affecting our original plans but completing the journey satisfactorily.

This accomplishment is proof of our team’s expertise, dedication, and tenacity to deliver projects under complex scenarios. We are happy to exceed our client’s expectations by providing a second to none service and clear communication throughout the process despite the challenges faced during the shipment.

Global Shipping Services handle Subsea Oilfield Equipment

GPLN member Global Shipping Services from USA handled recently a barge job going from Panama City/FL to Theodore/AL.

The commodity was 13 pieces of Subsea Oilfield Equipment, SFL/Cassettes and each piece had a dimension of 7.14m x 6.70m x 2.20m and a weight of 6,638 kg.

The Inland deck barge was a 280’ x 50’ x 12’ with dedicated tug.

The vessel departed Panama City in the early morning and arrived at the consignee facility in AL a few days later for discharge.

Due to lock issues along the inland waterway, it took three and half days to reach Panama City/FL.

PROTRANSER export Drilling Rigs

GPLN member PROTRANSER’s team from China delivered 2 sets of drilling rigs from Tianjin, China to Kolwezi, DRC. The total volume was 6 packages/ 43,740 kgs / 188.12 CBM. This equipment was shipped by Breakbulk vessel from Tianjin in China to Dar es Salaam, Tanzania, and delivered to jobsite in Kolwezi by trucks.