A Word From GPLN: Newsletters Issue 86 / May – June 2022

Dear Reader,

Our 17th GPLN AGM in Rotterdam in May 2022 was a great success. Over 140 GPLN members from 60 different countries came together during meetings and social events to discuss past, current and future business, exchange sales leads and develop business within the GPLN project network. This number of attendees was excellent result, considering the Covid situation and absence of our delegates from China, Russia, Belarus, etc.

Due this fact and adequate meeting facilities we will hold our next annual global conference from June 3-5, 2023 again at the Hilton Hotel in Rotterdam.

Right after our AGM on June 6, 2023 our renown Heavy Transport and Lifting Seminar will take place at the same venue and is available also for none GPLN members.

More details and delegate registration for both our AGM and Seminar are available on our dedicated websites: https://gpln.net/agm-2023/ & https://gpln.net/technical-course/

Both GPLN events can be combined with Breakbulk Europe which follows from June 6-8, 2023 at Ahoy Convention Center Rotterdam. GPLN will exhibit again at this event and has secured the same prime location in the main hall with a 36 sqm booth which is the equivalent to 4 regular stands. GPLN members who wish to share our stand should contact us well in advance as space is limited.

As part of this year’s conference GPLN held also a photo competition among members. The winning photo, provided by Best Global Logistics from the Netherlands, shows an image of one of several modules transported from China to Singapore, with the largest module standing about 34 meters tall and weighed 900 tons in total (see below).

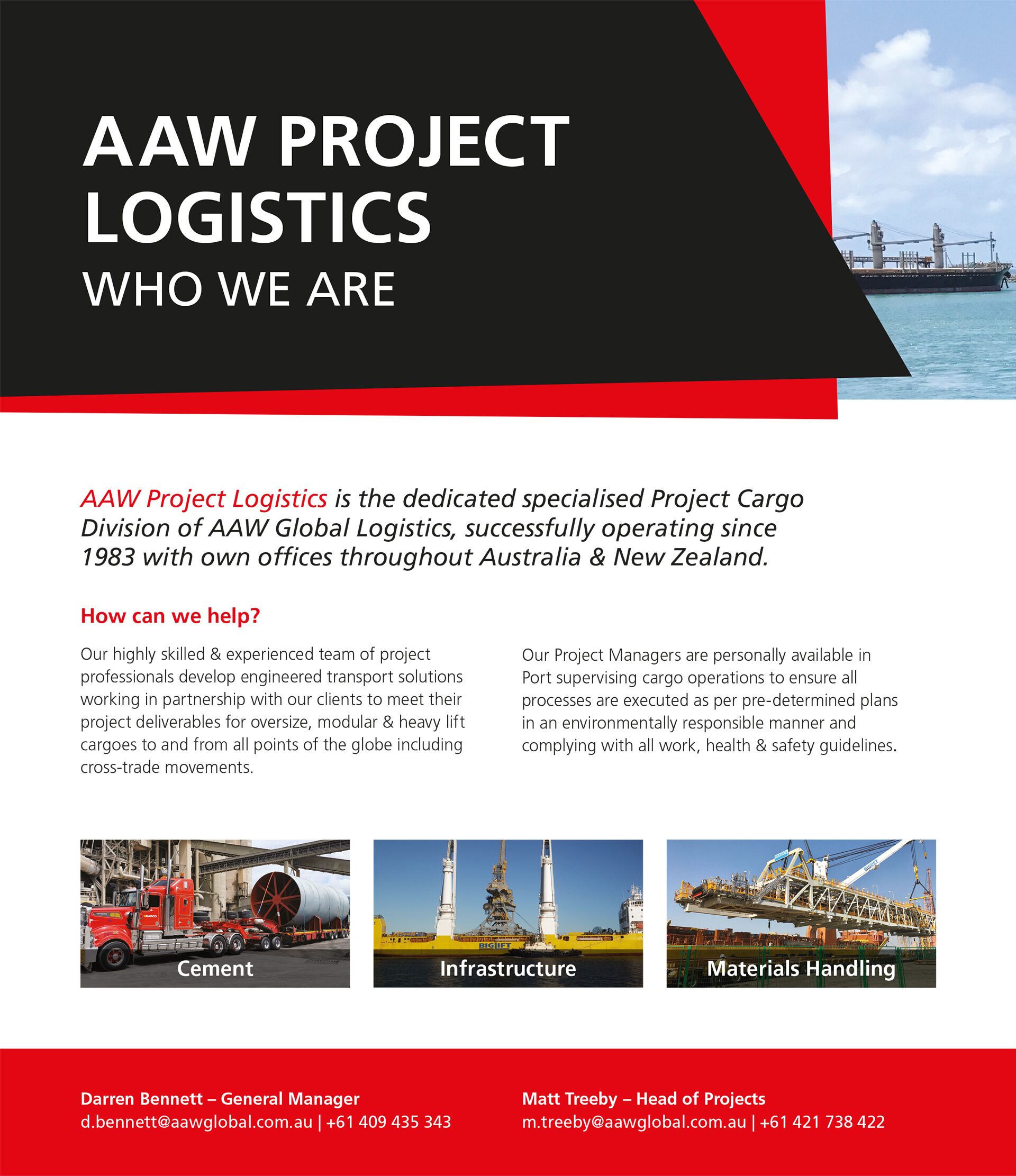

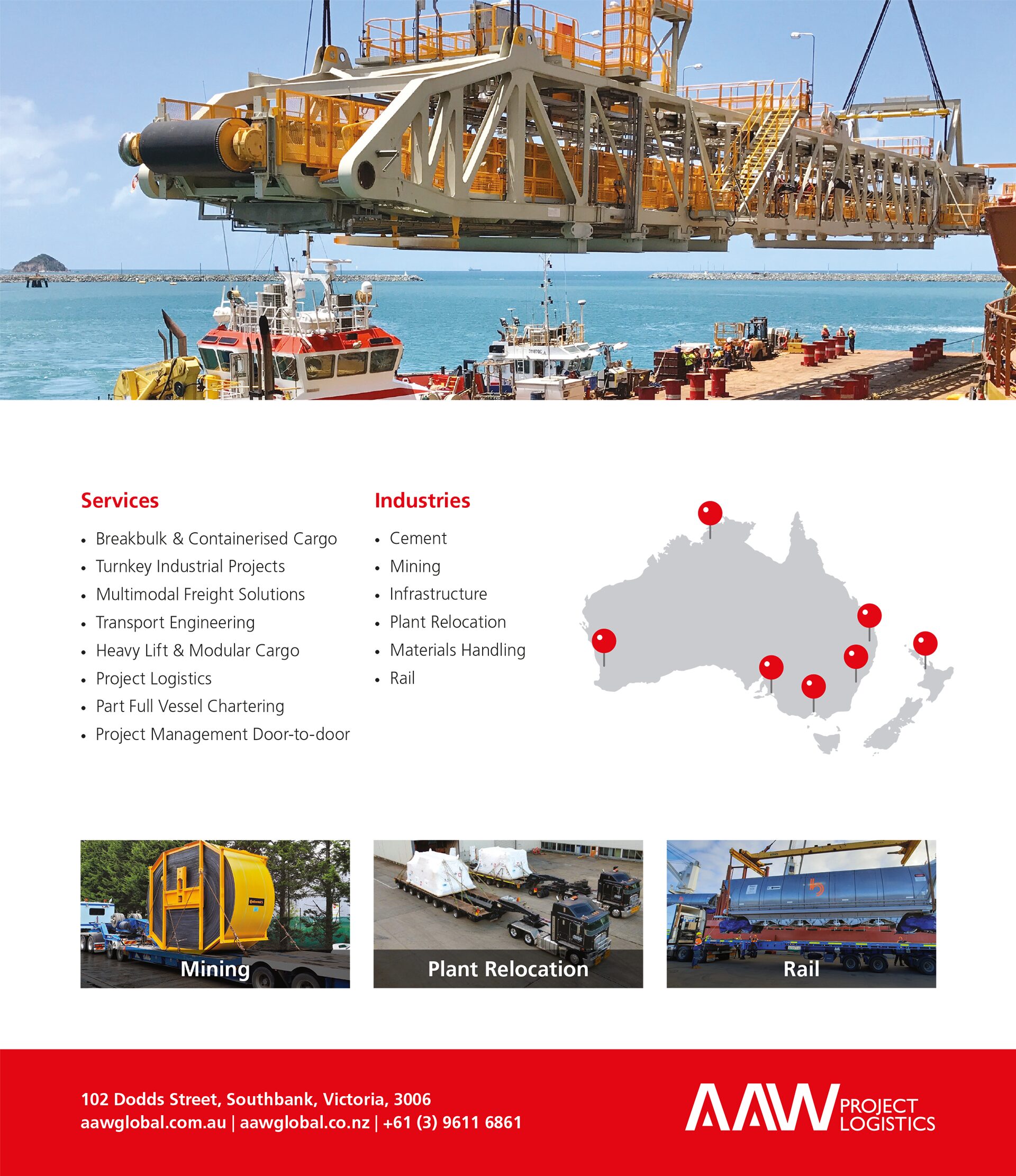

Furthermore, we would also like to take this opportunity to thank once more our sponsors for the great support of our conference. Please see below details:

Best regards,

Your GPLN team

Universal’s Trip to the stars

A highlight in the area of special transports: In June 2022, GPLN member Universal Transport from Germany transported a satellite for the ESA mission Earth CARE (Cloud, Aerosol and Radiation Explorer). It was the most valuable load in the company’s history. The satellite will be used as part of the Earth CARE mission, a joint venture between the European Space Agency and the Japanese space agency JAXA (Japan Aerospace Exploration Agency). The launch of this large and most complex earth exploration mission to date is scheduled for 2023.

The satellite was loaded in Immenstaad on Lake Constance. Three of the manufacturer’s employees joined the three-night transport in an escort vehicle. During the day, a security company kept a close eye on the valuable load, which was stored in a container for the transport.

“The challenge wasn’t the dimensions (4.2 m wide and nearly 4m high) or the weight of the freight for once, but the high value of such satellite,” explained branch manager Stephan Stender.

On June the 13th, the team started the first part of the journey from Lake Constance to the Hockenheim service station. After the second night, the convoy arrived at the border crossing in Venlo. The third stage led to the finish line at ESTEC in Noordwijk in the Netherlands. The European Space Research and Technology Centre is the technical heart of ESA, where most ESA projects such as Earth CARE are developed.

“It was a great honor for us to be able to carry out this special transport. After eight months of careful preparation, we were able to complete the order on time,” said project manager Maik Heese.

Earth CARE will use high-performance lidar and radar technology like never before in space. The aim is to provide data that will enable scientists to study the connection between clouds, aerosols and radiation with a level of detail previously not possible, to understand climate change processes better.

Megalift transport Splitting Columns

GPLN member Megalift from Malaysia handled recently two units of Splitting Columns in Port Klang. The dimension was (L) 30.65 m x (W) 3.90 m x (H) 4.20 m and weight 151 tons.

They successfully delivered two units of large Splitting Columns from the fabrication yard of their client to the jetty for an export shipment. Their client is one of the leading engineering companies in Malaysia specialising in fabricating oil and gas cargoes.

From the fabrication yard, Megalift cruised through the industrial terrains towards the location of the jetty. At the jetty, they drove in their hydraulic multi-axle trailers onto the barge before the team jacked down the cargoes. The roll-in operation had to be done swiftly to catch the brief interval of the water tide. Thankfully with years of experience, the Megalift team handled the operation really well.

|

New GPLN Members / May-June 2022 |

||

| India | Bangalore | Navio Shipping Pvt. Ltd. |

| India | Chennai | Navio Shipping Pvt. Ltd. |

| Iraq | Basra | Martrade Group |

| Qatar | Doha | Martrade Group |

| Turkey | Istanbul | Martrade Group |

| UAE | Abu Dhabi | Martrade Group |

| USA | Chicago | Falcon America LLC |

Conveyor delivers Pressure Vessels

GPLN member Conveyor Logistics Ltd. from Bangladesh has recently completed the delivery of 4 units of 100 cubic meter pressure vessels for Gandharbpur Water Treatment Plant Project. This is the largest water treatment plant being constructed in Bangladesh by Dhaka Water Supply and Sewerage Authority (DWASA). Conveyor Logistics Ltd. (CLL) has been working in this project as logistics and transportation service provider in partnership with Daher Technologies, France, employed by the main EPC contractor Suez OTV Veolia, a joint venture of Suez International and OTV Veolia. The pressure vessels have arrived in Chittagong Port on Flat Rack (FR) containers which have been discharged from mother vessel to port jetty site. Being large diameter pressure vessels and not suitable for road transportation, the pressure vessels had to be transported by waterway on tow-barge.

CLL was responsible for Customs clearance, loading on the tow-barge from a private jetty at Chattogram. A temporary jetty was built on the bank of Shitalakshiya river, nearby the project site, to discharge cargoes by using 150ton capacity lattice-boom, crawler crane, which was set on that barge.

The total weight of the pressure vessels was 91,800 MT and the total volume of the pressure vessels was approximately 741.813 CBM. 4 units of 9.522 meter long, 4.236 meter wide and 4.165-meter-high pressure vessels were received at the Chittagong Port on 1 flat tow-barge and were transported by waterway from Chittagong Port to the Water Treatment Plant project site at Gandharbpur, Rupganj, Narayanganj.

The distance from the Chittagong Port to the Project Site was approximately 290 km. We had to mobilize all heavy equipment, lifting devices, transporters by barge from Chattogram to the project site temporary jetty. The pressure vessels were hauled, from temporary jetty to the project site at Gandharbpur, by mechanical low-bed trailers.

Total Movements handle Multimodal Task

Successful Multimodal Movement for 590 MW Gas/Fuel Oil Power Plant in Bangladesh from the supplier’s factory in India to the load port, India. For this project, GPLN member Total Movements from India moved 5 units of Power Plant equipment’s and accessories with the widest piece being 8m and heaviest being 110 MT.

With the execution of the project being getting coincided with the fag end of the monsoon, detailed planning was carried out by our team. All the parameters on-road as well as on sea for cargo safety and stability were taken into consideration. The three ODCs by road were placed on suitable vehicles, lashed properly and moved out from the supplier’s plant to the load port.

The remaining two critical-shaped equipment (Neck) required extreme supervision as they were to be loaded on the barge by a LOLO operation that required a very high-capacity crane. This operation was executed under close supervision of our expert personnel, considering tidal factors and cargo safety.

The cargo was secured / lashed, moved by barge to the load port, brought alongside the vessel and loaded safely in a timely manner. A suitable technical study was done to ensure that everything goes according to plan. With support from all the stakeholders involved, the cargoes were loaded in a safe & timely manner.

Transmaritim international ship crane parts

GPLN member transmaritim international from Germany is always pleased to work on interesting projects in cooperation with their business partners. This time they successfully transported crane parts from Germany to South Africa on Mafi-Trailers by RORO vessel.

Bee Logistics handle various projects

GPLN member Bee Logistics Corporation from Vietnam were chosen by Thach Nham hydroelectric power plant for their equipment project.

They handled an equipment and machinery shipment by break bulk vessel for this hydroelectric power plant in Quang Ngai province, Vietnam. The full services covered customs clearance, land transportation and offloading heavy equipment at the job site.

Furthermore, Bee Logistics offered also a flexible and customized solution and completed a delivery project of oversized cargo from Da Nang port to VSIP Quang Ngai industrial zone. They handled a series of services, including getting approval on tax free portfolio for investment in fixed assets, customs clearance and inland delivery.

Despite a challenge the limited height of industrial zone gate did not trouble them. Unstuffing containers at Da Nang terminal was tailor-made and a flexible solution for a smooth delivery.

Ceta Logistics completes Gas Cooler Project

Another Gas Cooler Project that was carried out safely and quickly by GPLN member Ceta Logistics & Projects from Turkey. Thanks to our expert team and experience, we have recently completed logistic’s task and shipped Gas Coolers from Malaysia via Suleymaniyah in North Iraq to Khor Mor Gas Plant.

The total shipment consisted of 7000 CBM and each Gas Cooler had a weight of 44 tons and a dimension of 10m x 4,3m x 4,4m. We handled the cargo from Iskenderun Port to Sulaymaniyah and spent in total 1’300 km with the road freight.

ITM Projects brand-new jack and skidding sliding system

GPLN member ITM Projects from Mexico are ready to help with their offloading services for heavy cargo, with their brand-new jack and skidding sliding system. They can safely load, unload, or transfer any cargo up to 300 tons. Perfect for turbine rotors, transformers and much more and the ideal solution for remote or distant locations.

Star Shipping handles RORO shipment

GPLN member Star Shipping’s operation team from Pakistan handled a RORO project shipment during the Eid festival holidays at Karachi Port.

Cargo details: 2 units of Komatsu mechanical haul trucks with a total weight of 26 tons each, 1 unit of main body of Komatsu with a weight of 67 tons, 1 new unit of a complete colling tub Hydra Rig weighting 60 tons, and 21 various packages of accessories etc.

PROTRANSER handles multiple project cargo moves

GPLN member Protranser from China has recently delivered over 5300 CBM cargo for an energy project in Bangladesh by 4 lots including cables and 5 sets of transformers. It was a power grid system expansion and upgrade project which was signed during President Xi’s visit to Bangladesh in 2016. This project will promote the cooperation between Bangladesh and China on “One Belt, One Road”. The project consisted of over 4600 CBM cables and the weight and dimension of each one was 3 meters in diameter, 2 meters in width, and 10 tons in weight, whereas the weight of the main body of each transformer was 50 tons. The total value of these 4 lots of cargo was over 27 million dollars.

Our working scope included: collecting cargo at ports in Shanghai and Tianjin, chartering breakbulk vessel to Chittagong port, import customs clearance and delivering by trucks to the jobsite, 200 km away from the port.

Furthermore, they delivered 21 mining trucks from Shanghai port to jobsite in DRC via Durban port, South Africa. The weight of each one was from 25.9 tons to 31.7 tons, with a total volume of 2685 CBM. Working scope was from collecting cargo at Shanghai port, chartering breakbulk vessel from Shanghai to Durban and delivering trucks to DRC by low-bed trailers.

Protranser delivered as well 2 sets of excavators from Tianjin, North China, to Karachi, Pakistan by breakbulk vessel. The weight and dimension of each one was 21 tons and 9,75*2,85*3,25m, with a total volume of 4 packages / 42,264 kgs / 183 CBM. Our work scope included: picking up cargo from the factory, port service in Tianjin and chartering service from Tianjin to Karachi.

In another move Protranser delivered 6 sets of transformers from Wuhan, China to the Philippines by two lots. The gross weight of the main body was between 75 tons and 100 tons. The total volume was 167 packages / 714,764 kg / 1406 CBM. Working scope included: picking up cargo at factory in Wuhan, Central China, and delivery to Shanghai port by trucks.

Protranser’s team shipped also over 1500 CBM of tanks from Taicang, Jiangsu province to Callao, Peru. The longest tank was 25 meters. Due to the requirement of an epidemic control, tanks couldn’t be delivered directly to Taicang port by road and we therefore provided an alternative solution of delivering cargo to Jiangyin port by road and chartering a barge from Jiangyin port to Taicang port and reached the breakbulk vessel on time. Our working scope included: picking up cargo from factory, delivering to Jiangyin port by road, chartering barge from Jiangyin port to Taicang port and chartering Breakbulk vessel from Taicang port to Callao, Peru.

Finally, Protranser delivered 2 sets of tunnel trolleys from China to Tajikistan. The total gross weight of the cargo was 200 tons and all cargo was loaded on 7 trailers from Tajikistan. After repacking the cargo in steel frames at Karasu Port in Kashgar, Xinjiang province (according to the requirement of the port for Epidemic prevention and control,) it took 8 days to deliver the cargo to the jobsite in the mountains of Tajikistan via Dushanbe. We overcame the challenge of congestion at the border and the situation of snowmelt road collapse in Tajikistan and delivered the cargo to the jobsite on time.

EGL handles East-Owinat Substations

Hitachi ABB Power Grids provided state-owned Egyptian Electricity Transmission Company (EETC) with high-performance grid stabilization technology to help improve power quality and expand transmission capacity in the strategic Owinat development area in southwest Egypt, where desert wasteland is being reclaimed for agricultural use

On December 2021, a consortium had been established between GPLN member Egyptian Global Logistics (EGL) of Kadmar Group / Hitachi Energy / German Logistics Group, in order to handle the first statcom power transformer in Egypt’s history from Alexandria port to East-Owinat site. Two transformers (128 tons each) were shipped from Antwerp on a gearless vessel and off-loaded by 2 heavy-lift cranes at Alexandria port with a special arrangement with Port Authority and pre-technical engineering planning in cooperation with the German Logistics Group to guarantee a smooth port operations due direct delivery from crane hook to job site.

Scope of work: Lifting and transport engineering. Port, Route and site survey. Supply of two mobile crane 500 tons each to offload transformers into EGL trailers. Road permits from utilities. Transportation of transformers from port to site. Offloading to foundations by hydraulic jacks.

Challenges: Transport distance from port to site around 1,600 km.

Reconfigurations of hydraulic axles from 16 to 8 axles in order to reach foundation center. Total skidding distance for two transformer @ 45 meters. Rotations transformer 90ᵒ degrees. Site entrance not easy due many H.V cables 500KV and 220KV. Foundations access curved and sloped (25 degrees). Executions area width 6 meter only between control room and transformers foundations.

GPLN Duo handle Break Bulk Cargo

In the first semester of 2022, GPLN member Cargo Way from South America handled a cooperation shipment with GPLN partner Contitrans from Germany. The break bulk cargo was routed from China by Contitrans to Obligado city in Paraguay. Cargo Way was appointed as the South American agent, responsible for determining the best-suited discharging port – Imbituba, Brazil – for port operation and special bonded trucking to Paraguay. Customs strikes and port congestion were the unusual challenges that were well mitigated by the team, covering all the needs in South America.

“This shipment reinforced the importance of being part of GPLN and jobs between partners always end up in better service to the customer. “We are very proud of this operation.” said Rafael Catarino – COO of Cargo Way.